Direct to Film, abbreviated as DTF, is a relatively new printing technique in the world of textile printing. Unlike traditional methods such as screen printing and direct digital textile printing (DTG), DTF first prints the image onto a special film. This film is then transferred to the textile using a heat press.

Direct to Film, or DTF, is a promising technique that is becoming increasingly popular. The combination of high quality, versatility and flexibility makes DTF an excellent choice for companies looking for a reliable and efficient way to print textiles.

Although DTF delivers excellent results, it does require a higher level of maintenance and regular attention. It is therefore especially suitable for companies that are prepared to invest in time and expertise.

Read more

Who is direct to film suitable for?

Direct to Film (DTF) is a versatile printing technique that can be interesting for different target groups. Below you will find an overview of the typical profiles that benefit from DTF:

Companies and entrepreneurs

- Clothing companies: Both large and small clothing brands can use DTF to print t-shirts, hoodies, sportswear and more. It is ideal for short runs, prototypes and personalized products.

- Promotion and advertising agencies: DTF is perfect for creating promotional items such as printed clothing, bags and caps. The fast switching between designs makes it ideal for campaigns with different visuals.

- Sports clubs: For sports clubs, DTF is a good choice for printing tracksuits, shirts and other team clothing.

- Companies with their own brand shop: With DTF, companies can set up their own merchandise line and adapt it to the latest trends.

Creative entrepreneurs and hobbyists

- Designers: DTF offers designers a great deal of freedom to express their creativity. They can realize complex designs with many details and colors.

- Artists: Artists can transfer their artwork onto textiles and sell them as unique pieces.

- Hobbyists: For people who like to print clothes themselves, DTF is an accessible and versatile technique.

What do you need to work with DTF?

To work with Direct to Film (DTF), you need a number of specific equipment and materials. Below is an overview:

Essential equipment and materials for DTF:

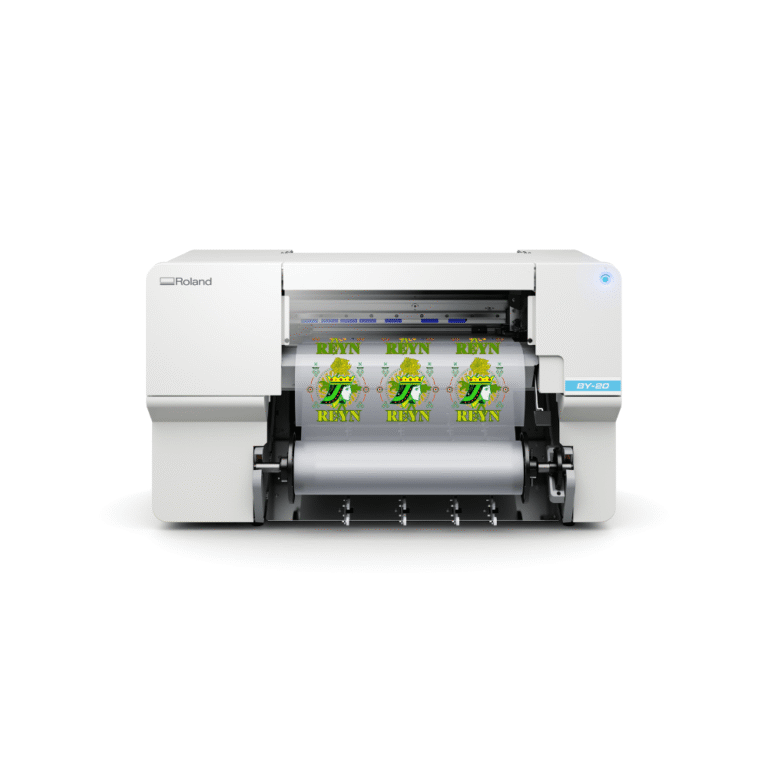

- DTF printer: This is the core of the system. A DTF printer is specially designed to print on a special transfer film.

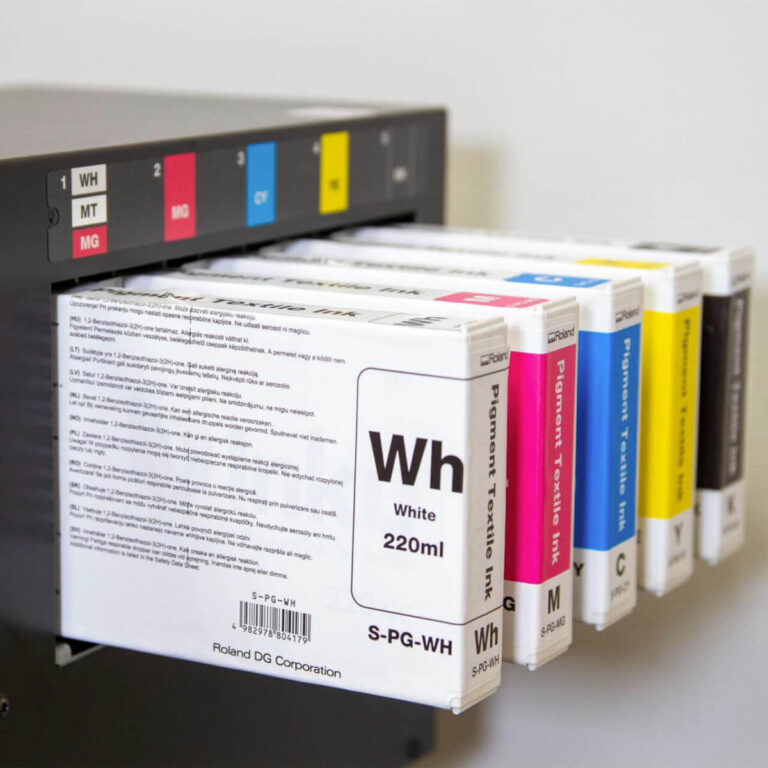

- DTF ink: This ink is specially formulated for DTF printers and adheres well to the film and the textile.

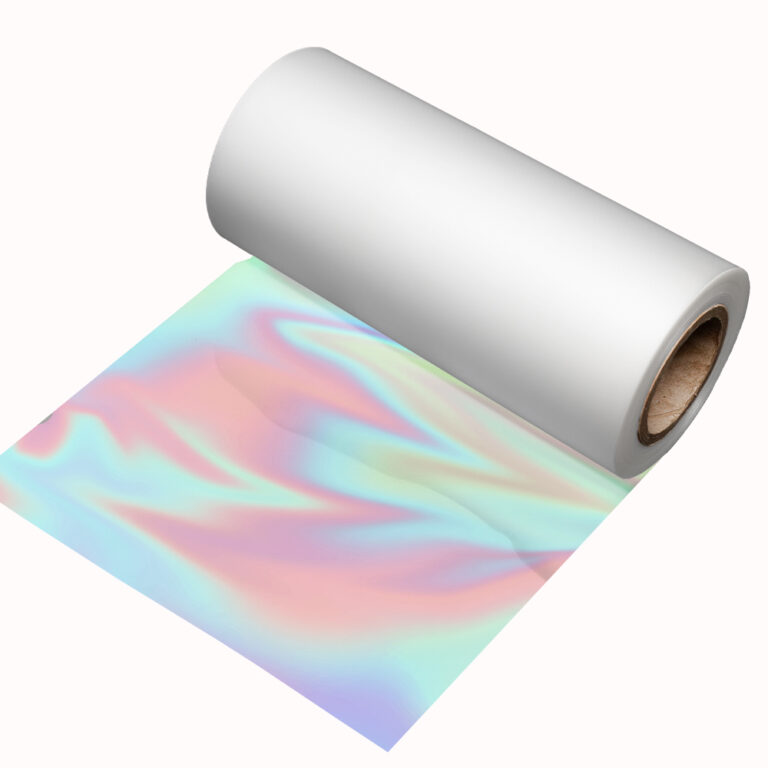

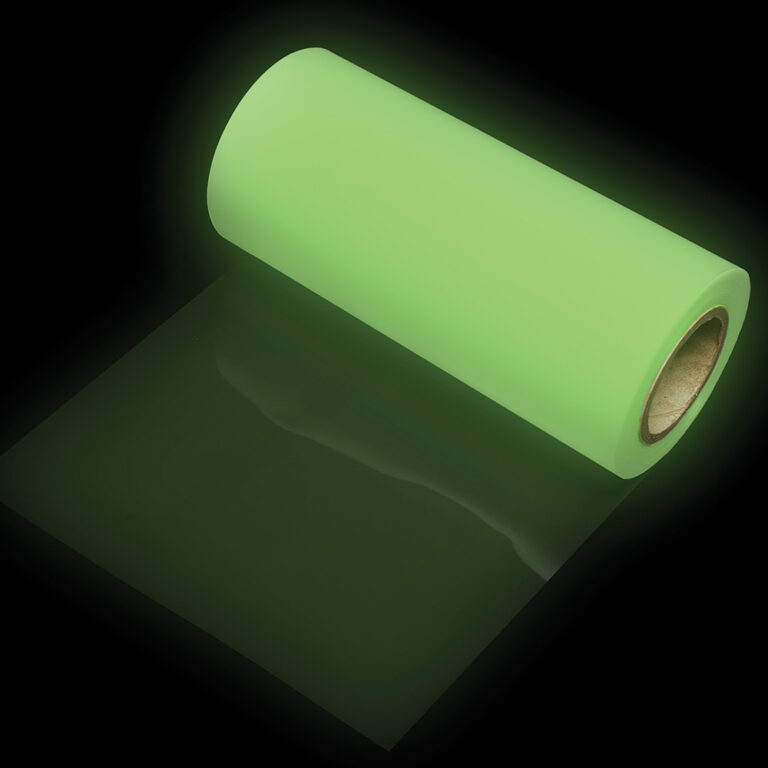

- DTF film: A transparent film on which the image is printed.

- DTF powder: This powder is applied to the wet ink and ensures a strong bond between the ink and the textile.

- Powder shaker: A machine that evenly distributes the powder over the printed film and removes excess powder.

- Heat press: To fix the powdered film to the textile.

- RIP software: This software prepares the designs for the DTF printing process.

Optional equipment:

- Pretreatment machine: For certain types of textiles, a pretreatment may be necessary to ensure better adhesion. guarantee.

- Automatic feeder: This can speed up the production process by automatically loading the film into the printer.

- Cutter: To cut the printed film to size.

Important considerations when choosing DTF:

- Cost: DTF equipment and materials can be a significant investment.

- Space: You need enough space for the equipment and production process.

- Maintenance: DTF printers require regular maintenance to ensure optimum performance.

- Quality of prints: The quality of the prints depends on the quality of the equipment, the ink, and the operator.

What should I pay attention to with Direct to Film?

When working with Direct to Film (DTF), there are a number of important things you should pay attention to in order to achieve optimal results:

Quality of the materials

- DTF ink: Always use high-quality DTF ink that is specially designed for your printer and textile type. A good ink ensures vibrant colours and a durable print.

- DTF film: Choose a film that can withstand high temperatures and adheres well to the textile.

- DTF powder: The powder must be finely dispersed and melt well to create a strong bond.

Printer settings

- Profiles: Use the correct colour profiles for your printer and textile type to ensure accurate colour reproduction.

- Density: Adjust the ink density to the design and textile. Too much ink can lead to a clogged print head, while too little ink can result in a faded print.

- Temperature: The temperature of the heat press is crucial for fixing the print. Too low a temperature can lead to a loose print, while too high a temperature can damage the fabric.

Preparing the fabric

- Washing instructions: Always follow the washing instructions of the fabric to prevent shrinkage and color change.

- Pretreatment: Some fabrics, such as polyester, require pretreatment to improve the adhesion of the print.

- Environmental factors

- Temperature and humidity: Extreme temperatures and humidity can affect the quality of the prints. Ensure a stable environment.

- Dust: Keep the workspace clean to prevent dust particles from getting on the prints.

Equipment maintenance

- Cleaning: Clean the print head and other parts of the printer regularly to prevent clogging.

- Calibration: Calibrate the printer regularly to keep the color reproduction accurate.

Other considerations

- Design: Keep the limitations of DTF in mind when designing your images. Small details and fine lines can be lost during the printing process.

- Textile type: DTF is suitable for many different textile types, but some materials require special treatment.

- Testing: Always perform a test print on a sample piece before printing a large print run.

By taking these considerations into account, you can significantly improve the quality of your DTF prints and ensure your customers are satisfied.

What DTF films are there?

Pros and Cons of Direct to Film

Direct to Film (DTF) is an increasingly popular technique in the world of textile printing. It offers many advantages, but there are also some disadvantages that you should be aware of.

Advantages of DTF

- Versatility: DTF is suitable for a wide range of textiles, from cotton to polyester.

- High quality: Prints are vibrant, sharp and have a soft handfeel.

- Durability: DTF prints are wash-resistant and wear-resistant.

- Flexibility: DTF is suitable for both small and large print runs.

- Fast drying time: Prints dry quickly, allowing you to quickly continue production.

- Preparatory work: DTF prints can be created and saved in advance, allowing them to be applied quickly when needed.

- White ink: DTF allows you to use white ink, which means you can print on dark fabrics.

- Detail level: DTF can produce very detailed images.

DTF disadvantages

- Investment costs: Purchasing a DTF printer and the associated materials can be a significant investment.

- Maintenance: DTF printers require regular maintenance to ensure optimum performance.

- Preparation: Preparing the film and applying the powder takes time.

- Environmental impact: Although DTF is more environmentally friendly than some other printing techniques, it still produces waste.

- Limitations for complex designs: For very complex Designs with many small details can cause problems during the printing process.

Summary

DTF is a versatile and promising technique that is becoming increasingly popular. The combination of high quality, versatility and flexibility makes DTF an excellent choice for companies looking for a reliable and efficient way to print textiles.

What do DTF films cost?

| DTF Films | Price per meter* | Costs* (A4 logo) | Printing costs* | Powder | Total A4 print* |

|---|---|---|---|---|---|

| TheMagicTouch DTF Film Base, width 60 cm | €1.39 | €0.16 | €0.20 | €0.13 | €0.49 |

| TheMagicTouch DTF Film Premium, width 60 cm | €1.79 | €0.21 | €0.20 | €0.13 | €0.54 |

| TheMagicTouch DTF Film Reflective, width 30 cm | €4.99 | €1.15 | €0.20 | €0.13 | €1.48 |

| TheMagicTouch DTF Film Foil Gold, width 30 cm | €2.99 | €0.69 | €0.20 | €0.13 | €1.02 |

| TheMagicTouch DTF Film Foil Gold, width 30 cm | €2.99 | €0.69 | €0.20 | €0.13 | €1.02 |

* The prices mentioned are an indication based on the DTF Printer Transfer Pro 40 and can vary considerably. Factors such as humidity, complexity of design, chosen settings and required maintenance can strongly influence ink and powder consumption. This can result in higher final printing costs. Test prints and maintenance prints are not included in the price.

What is UV DTF Printing?

UV Direct-to-Film (UV DTF) printing is a cutting-edge transfer technology that combines the vibrance of UV-curable inks with the versatility of film transfers. Unlike textile-based DTF, UV DTF is specifically engineered for hard substrates. It creates durable, scratch-resistant stickers that allow for high-quality branding on materials previously difficult to print on directly.

Key Applications: Ideal for personalizing tumblers, glass, metal, wood, plastic, ceramics, and acrylic.

The UV DTF Advantage: No Heat Press Required

The most significant evolution in this technology is the application process. Unlike traditional DTF, UV DTF eliminates the need for a heat press. This allows for seamless application on:

- Irregular Shapes: Curved or uneven surfaces where a flat press cannot reach.

- Heat-Sensitive Materials: Substrates that might warp or melt under traditional heat transfer methods.

- 3D Textured Effects: By layering ink and varnish, you can create “raised” or tactile stickers with a premium 3D finish.

Print on Almost Anything

Break free from the constraints of flatbed printing. With UV DTF transfers, your branding potential is unlimited by shape or size.

Popular Substrates Include:

- Sporting Goods: Helmets and Skateboards.

- Homeware: Flower Pots, Wine Glasses, and Mugs.

- Electronics: Laptops and Electrical Devices.

- Industrial: Signage and prototypes on wood, acrylic, or metal.

How Does UV DTF Printing Work? (Step-by-Step)

- Preparation: The protection layer is removed from Film A to expose the adhesive.

- Printing & Curing: Designs are printed directly onto the adhesive. The UV lamps “cure” (harden) the ink instantly, bonding it to the adhesive.

- 3D Layering: Because the ink cures instantly, multiple layers can be printed to create a raised, textured effect.

- Lamination: As the film exits the printer, Film B is laminated over the top to protect the design.

- Application: Peel Film B (which carries the design), position it on your substrate, and apply firm pressure from the center outwards.

- Finishing: Remove the transfer tape (Film B), leaving a permanent, high-durability graphic on the object.

What do you need?

- UV Film A: The specialized carrier film with a printable adhesive layer.

- UV Film B: The lamination/transfer film that encapsulates the design for easy application.

Frequently asked questions about Direct To Film / UV DTF Film

What exactly is Direct to Film (DTF) printing?

Direct to Film is a modern printing technique where designs are digitally printed onto a specialized clear PET film. After the ink is applied, a unique adhesive powder is layered onto the wet ink and cured with heat. This creates a flexible transfer that can be heat-pressed onto almost any fabric.

2. Which materials are compatible with DTF?

One of DTF’s greatest strengths is its versatility. Unlike Sublimation (polyester only) or DTG (mainly cotton), DTF works perfectly on:

* Cotton and organic blends.

* Polyester and high-performance sportswear.

* Nylon and treated synthetic fabrics (like softshells).

* Blended fabrics such as poly-cotton or tri-blends.

How durable is a DTF print?

DTF prints are highly durable and stretchable. Because the ink is bonded to the fabric via a specialized adhesive layer, the print does not crack or peel easily. It maintains color vibrancy even after numerous washes (up to 60°C) and offers a softer “hand-feel” compared to traditional vinyl or screen print transfers.

What is the difference between DTF and Screen Printing?

While Screen Printing is cost-effective for massive bulk orders with limited colors, DTF excels in detail and flexibility. DTF allows for photo-realistic images and complex color gradients without the high setup costs of screens. This makes it the superior choice for small to medium-sized orders requiring high-quality detail.

Can I use a regular inkjet printer for UV DTF?

No. UV DTF requires specialized UV-curable inks and UV lamps to harden the ink instantly. Standard inkjet inks will not bond to the adhesive film.

What equipment is needed to start UV DTF printing?

You will need a dedicated UV DTF Printer (like the Mimaki UJV300DTF-75), UV Film A & B, UV-curable inks, and a felt squeegee for professional application.

How long do UV DTF transfers last?

When applied correctly, UV DTF transfers are incredibly durable and can last up to 5 years under normal conditions.

Why is my UV DTF transfer peeling?

Peeling usually occurs due to insufficient pressure during application. We recommend using a felt squeegee to ensure the adhesive bonds fully to the edges of the substrate.