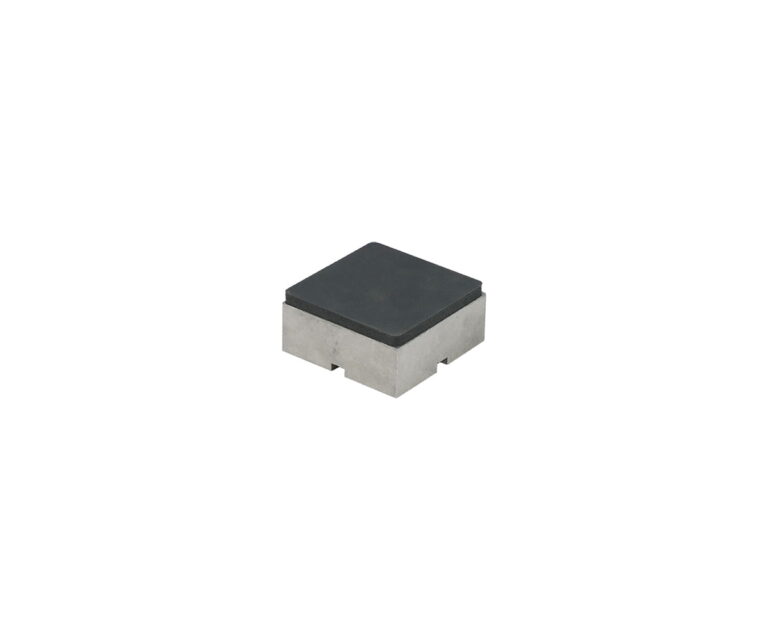

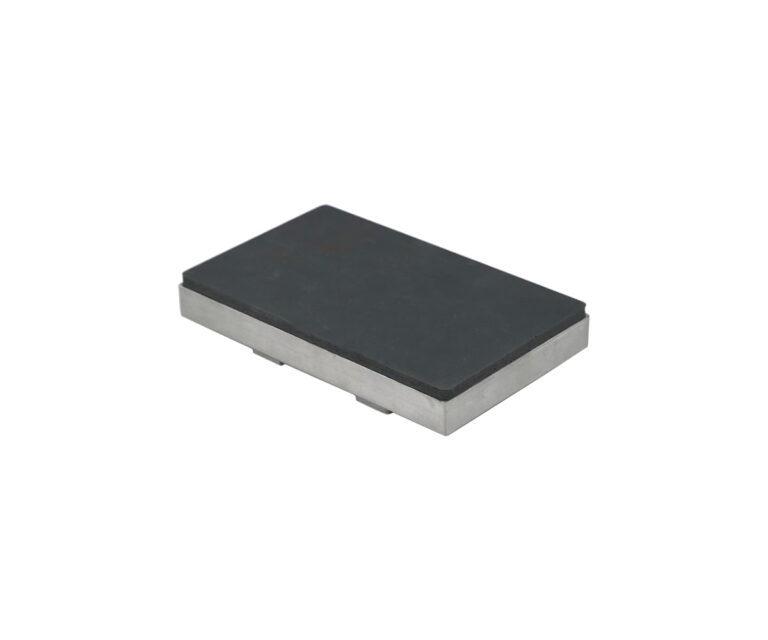

The Bottom Platen Heat Press is the stationary lower base plate of a heat press machine that serves as the work surface for positioning garments or substrates. Unlike the upper platen (the heat element), the bottom platen is typically unheated and is equipped with a heat-resistant silicone or rubber foam pad to provide a cushioned, stable pressing area.

Read more

Why It Matters: Impact and Use

The bottom platen is essential for achieving professional-grade results, understanding the role of the lower platen is vital for technical troubleshooting and production efficiency.

- Interchangeable Options: High-end presses allow users to swap the standard bottom platen for smaller versions (e.g., for sleeves, neck labels, or shoes). This is a key technical aspect for specialized decorators.

- Pressure Distribution: The silicone pad on the bottom platen is designed to be flexible. This allows it to absorb the “thickness” of seams, buttons, or zippers, ensuring that the actual print area receives even pressure. Without this flexibility, the heat press would only exert pressure on the thickest part of the garment, leading to transfer failure.

- Product Stability: The rubber surface provides grip, preventing the garment or transfer paper from shifting (ghosting) when the press is closed or opened.

- Versatility via Threadability: Many professional heat presses feature “threadable” bottom platens. This allows the operator to slide a garment over the platen so that only one layer of fabric is being pressed, eliminating the risk of transfers bleeding through to the back of the shirt.

All clamshell Heat Presses

Technical Components of the Bottom Platen

| Component | Technical Function | Maintenance Tip |

| Base Plate | Heavy-duty aluminum or steel structure that provides rigidity. | Ensure the base remains level and bolted securely. |

| Silicone Foam Pad | Provides the “rebound” necessary for even pressure. | Replace if it becomes permanently indented or loses its “squish.” |

| Platen Cover | A Teflon or fabric wrap that protects the silicone pad. | Keep clean of adhesive residue to prevent staining garments. |

Frequently Asked Questions

What is the purpose of the rubber pad on the bottom platen?

The rubber or silicone pad provides a cushioned surface that compensates for uneven areas like seams or zippers, ensuring that the heat press applies equal pressure across the entire transfer design.

Can I change the bottom platen on my heat press?

On many professional-grade machines (like TheMagicTouch HTP123 Pro or TheMagicTouch HTP256 Plus), the bottom platen is interchangeable. You can swap the standard plate for smaller sizes to press sleeves, bags, or infant-sized apparel more easily.

Is the bottom platen heated?

In most standard clamshell or swing-away presses, the bottom platen is unheated. However, specialized ‘Dual Heat’ presses exist where both the top and bottom platens are heated for specific technical applications like double-sided patches or heavy-duty foil.