The Controller is the central electronic processing unit—often referred to as the “brain”—of a heat press. It consists of a printed circuit board (PCB), a digital display, and interface buttons that allow the operator to program and monitor the three critical variables of heat transfer: Time, Temperature, and Pressure.

Read more

Why It Matters: Impact and Use

A high-precision controller is the foundation of a professional garment decoration workflow. In an industry where accuracy is paramount, the quality of the controller directly reflects a shop’s trustworthiness.

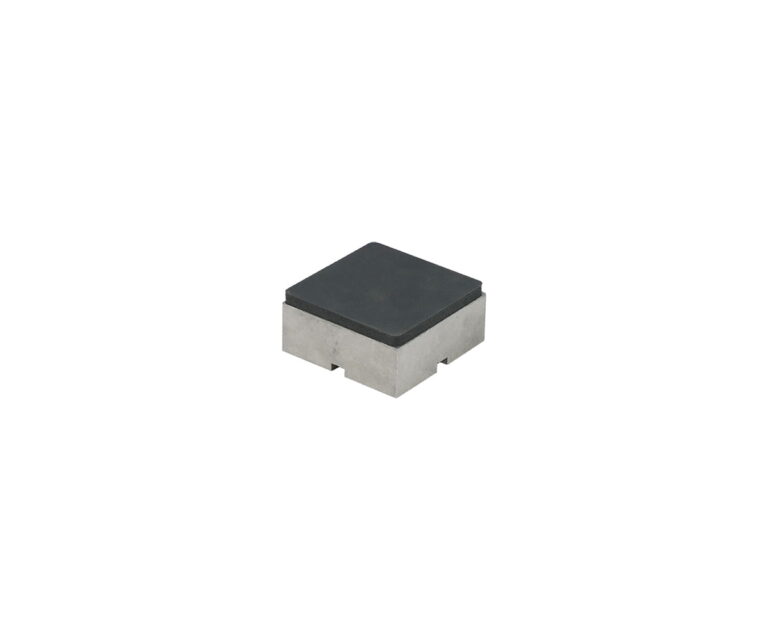

- Serviceability: On professional models, the controller is often a modular, self-contained unit. This “plug-and-play” design allows the user to replace the entire brain of the machine in minutes without professional electrical help, minimizing downtime and maximizing productivity.

- Thermal Regulation: The controller manages the heating element using logic (often PID control) to ensure the platen reaches the set temperature and stays there. Cheaper controllers may “swing” significantly in temperature, leading to inconsistent transfers.

- Timing Accuracy: Precision timing is essential for delicate foils or high-speed Direct to Film (DTF) transfers. A reliable controller ensures that a 15-second press is exactly 15 seconds every time.

- Advanced Features: Modern digital controllers often include production counters (to track daily output), “standby” or “eco” modes to save energy, and programmable presets for switching quickly between different transfer types.

All clamshell Heat Presses

Technical Components of a Controller

| Component | Technical Function | Importance |

| Microprocessor | Processes data from the temperature sensor (thermocouple). | Ensures logic-based heating to prevent “hot spots.” |

| Relay / SSR | Switches the power to the heating element on and off. | Critical for maintaining a steady temperature profile. |

| LCD/LED Display | Provides real-time feedback on current vs. set temperature. | Vital for user-monitored quality control. |

| Interface Buttons | Allows for the input of specific application “recipes.” | Simplifies the transition between different media. |

Frequently Asked Questions

What does the controller on a heat press do?

The controller regulates the heating element’s temperature and manages the countdown timer. It ensures that the press operates at the specific settings required for different transfer materials.

Can I replace the controller on my heat press myself?

On many professional models, the controller is designed as a modular unit. If the screen or buttons fail, you can usually swap out the entire control box with basic tools, avoiding the need for a full machine replacement.

Why is my heat press temperature fluctuating on the display?

Minor fluctuations (1-3 degrees) are normal as the controller cycles power. Large fluctuations often indicate a failing controller relay or a loose thermocouple (temperature sensor) connection.