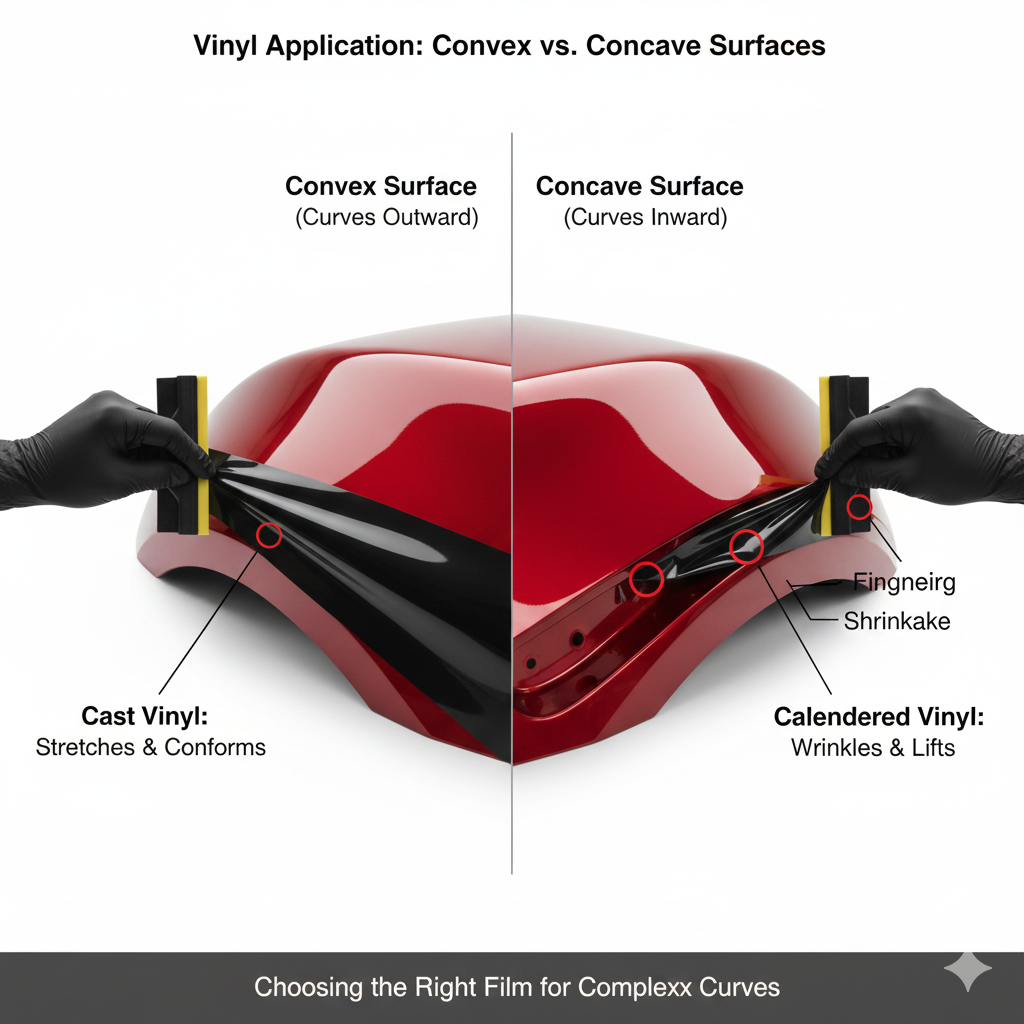

Why It Matters: Impact and UseIn the context of signage and decal application, Convex refers to a surface that curves outward, like the exterior of a ball or a vehicle fender. It is the geometric opposite of concave (which curves inward). When applying self-adhesive vinyl to a convex surface, the material must stretch or “fan out” to accommodate the increasing surface area of the curve.

Read more

Why It Matters: Impact and Use

Understanding surface geometry is a fundamental technical skill in the graphics industry. Improperly addressing a convex curve leads to common installation failures.

- Durability: Surfaces like motorcycle helmets, car bumpers, and gas tanks are almost entirely convex. Success on these substrates requires matching the correct film conformability to the degree of convexity.

- Material Stress: As vinyl is applied over a convex peak, it is pulled in multiple directions. If the wrong type of vinyl is used, the internal tension will cause the edges to lift—a failure known as “fingering.”

- Selection of Cast Vinyl: For complex convex surfaces, Cast Vinyl is essential. Because cast vinyl is manufactured without tension (liquid-state casting), it can be heated and molded to the outward curve without the “memory” effect that causes cheaper calendered films to shrink back to their original flat shape.

- Installation Technique: Installers often use a “bridge and heat” method on convex surfaces, where the vinyl is stretched slightly before being squeegeed down to ensure a smooth, wrinkle-free finish.

All Concave Vinyls

Technical Comparison: Surface Challenges

| Surface Type | Shape | Vinyl Reaction | Recommended Film |

| Convex | Curves Outward | Needs to stretch/expand. | Cast Vinyl (High Conformity) |

| Concave | Curves Inward | Needs to compress/recess. | Cast Vinyl (with Primer) |

| Flat | Level | No deformation required. | Calendered or Cast |

Frequently Asked Questions

What is the difference between convex and concave surfaces in vinyl wrapping?

A convex surface curves outward (like a dome), requiring the vinyl to stretch. A concave surface curves inward (like a bowl), requiring the vinyl to be tucked into a recess. Convex surfaces are generally easier to wrap than deep concave recesses.

Why does vinyl peel off convex surfaces?

This usually happens due to ‘mismatching’ the material. If a calendered vinyl is stretched over a convex curve, its ‘material memory’ will eventually cause it to shrink back, leading to edge lifting or wrinkles.

Which vinyl is best for convex curves?

Cast vinyl is the gold standard for convex surfaces. It is thinner and more stable than calendered vinyl, allowing it to conform to outward curves and stay in place permanently.