Definition: A Decal Transfer Paper, commonly known as a Waterslide Transfer, is a specialized media consisting of a thin, flexible lacquer or polymer film on a water-soluble paper carrier. When the printed media is submerged in water, the adhesive bond between the film and the paper dissolves, allowing the “decal” to slide off and be applied to smooth, non-porous surfaces.

Read more

Why It Matters: Impact and Use

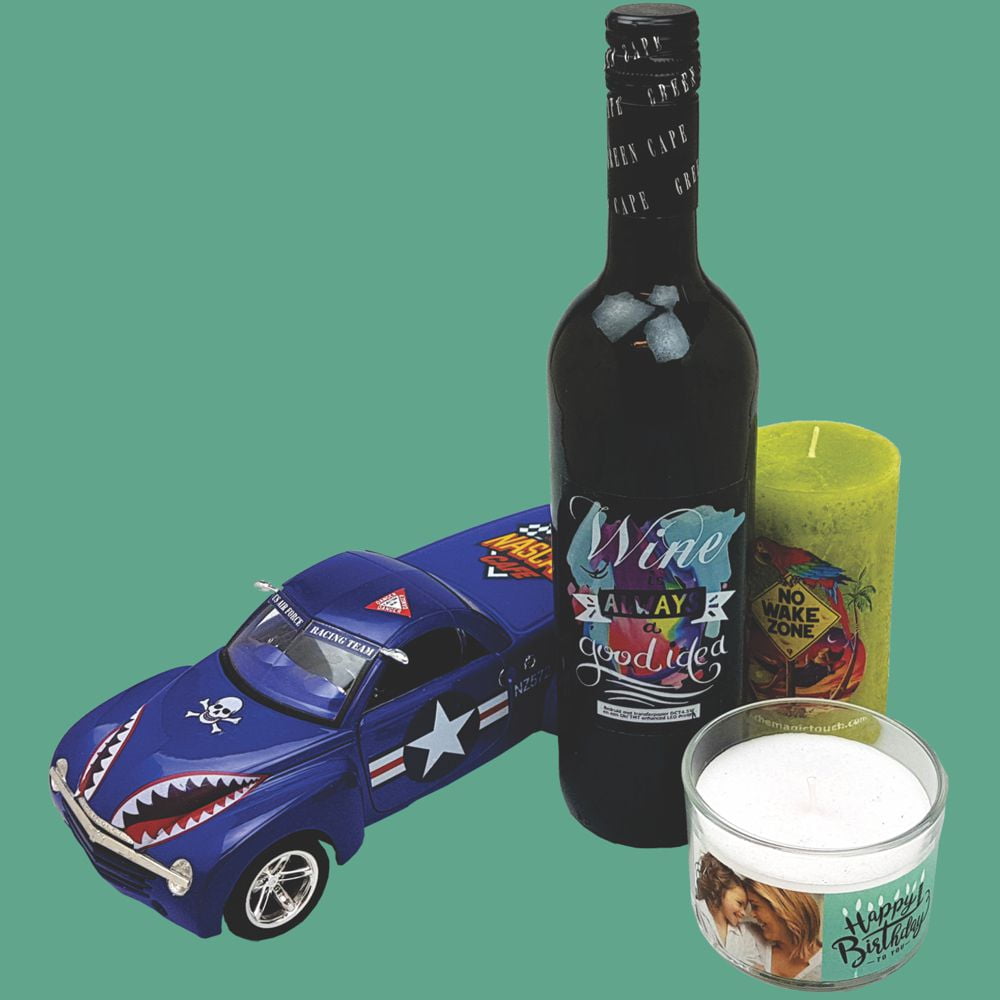

- Decal transfers are essential for decorating heat-sensitive or irregularly shaped items that cannot fit into a standard heat press. Mastering this technique demonstrates higher expertise in specialized product decoration.

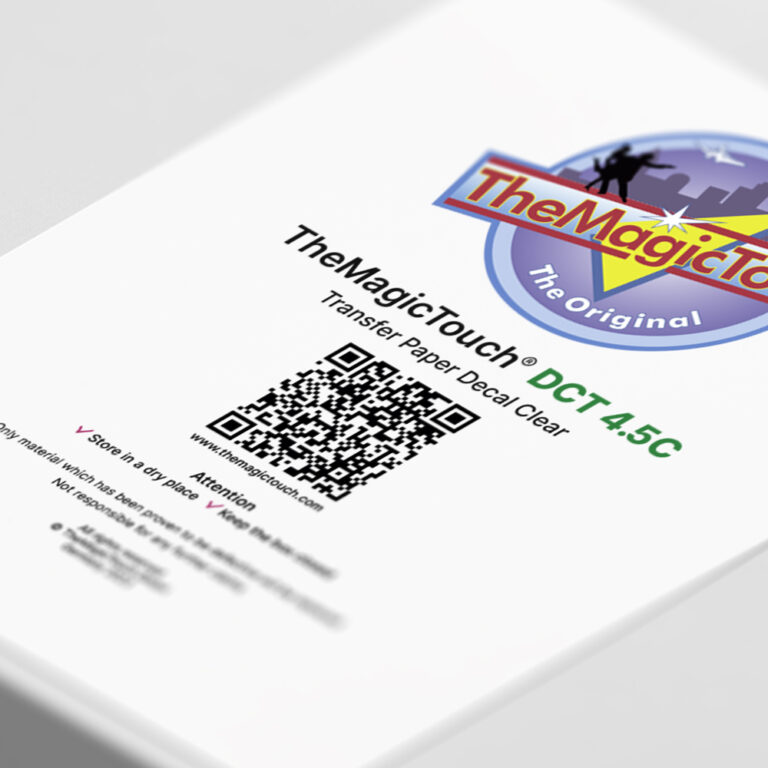

- DCT 4.5 Light C: A thinner version for even more seamless integration on light surfaces.

- Heat-Free Application: Unlike traditional heat transfers, decal transfers do not require high temperatures to bond. This makes them the primary solution for materials like candles, model airplanes, glass, and delicate ceramics that might crack or melt under a heat press.

- Ultra-Thin Profile: The transfer layer is microscopic in thickness, allowing it to conform to complex curves and contours. Once dried, it sits flush with the surface, often mimicking a factory-printed finish.

- Substrate Versatility: While often used for hobbies, professional-grade papers like TheMagicTouch DCT 4.5 series allow for commercial branding on industrial products, sports equipment, and home décor.

- Color Optimization: * DCT 4.5C (Clear): Ideal for light-colored or transparent surfaces where the background should show through.

- DCT 4.5W (White): Provides an opaque background for vibrant colors on dark or black substrates.

All clamshell Heat Presses

Technical Application Workflow

| Step | Action | Technical Note |

| 1. Print | Laser/LED Printing | Use the correct media setting to ensure toner fusion without melting the film. |

| 2. Soak | Water Submersion | Typically 30–60 seconds until the film “slides” freely on the paper. |

| 3. Position | Wet Application | The water acts as a lubricant, allowing you to slide the decal into the perfect position. |

| 4. Squeegee | Moisture Removal | Use a soft rubber squeegee or cloth to remove all air bubbles and excess water from underneath. |

| 5. Cure | Drying/Baking | Air dry for 24 hours or “oven-cure” at low temps (if the substrate allows) for increased durability. |

Frequently Asked Questions

What is the difference between DCT 4.5C and DCT 4.5W?

DCT 4.5C is clear and best for light surfaces. DCT 4.5W has a white carrier layer, which is necessary when applying transfers to dark or black objects so that the colors remain visible and opaque.

Are waterslide decal transfers dishwasher safe?

Standard waterslide decals are generally for decorative use and are water-resistant but not dishwasher safe. For items like mugs, hand-washing is recommended.

Why is my decal transfer peeling off?

Peeling usually occurs if air bubbles or water were trapped under the film during application. It is vital to use a squeegee to remove all moisture and to ensure the surface is completely free of grease or wax before applying.