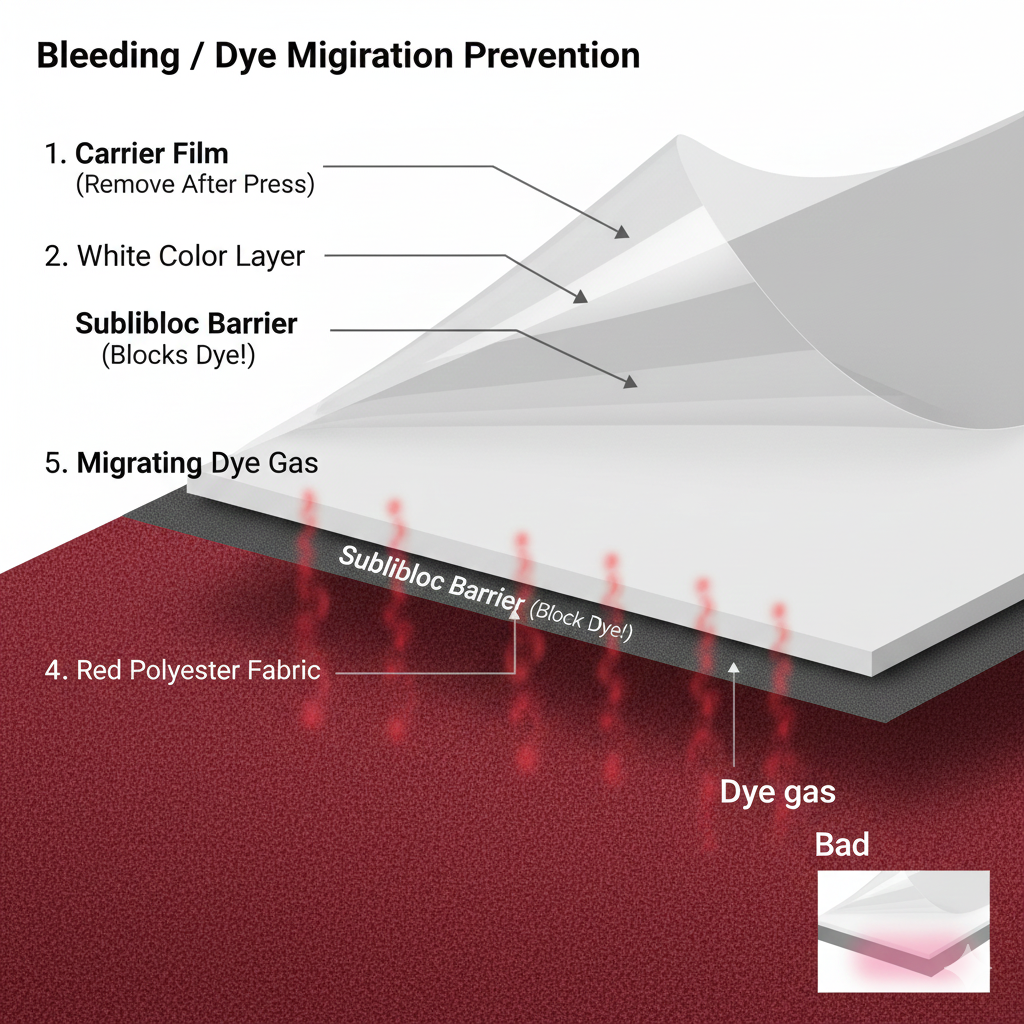

Bleeding, technically known as dye migration, is a chemical reaction where the dispersed dye pigments in synthetic fabrics (primarily polyester) become gaseous when heated and penetrate the color layer of the applied heat transfer material (flex foil or vinyl). This results in the garment color “bleeding” through the design, often changing white transfers into a muddy pink or grey.

Read more

Why It Matters: Impact and Use

In high-end garment decoration, bleeding is a major quality control hurdle. It often appears hours or even days after the pressing process, which can lead to costly customer returns and damage your brand’s E-E-A-T (Expertise, Authoritativeness, and Trustworthiness).

- Aesthetic Integrity: A crisp white logo on a red jersey turning pink is a sign of “amateur” production. Using the right technical materials prevents this “ghosting” effect.

- Delayed Failure: Because bleeding is a slow reaction triggered by the residual heat of the press, a product may look perfect during packaging but arrive at the customer’s door discolored.

- Substrate Sensitivity: The risk is significantly higher on Softshell jackets and 100% polyester sports jerseys. These garments are heavily dyed, providing more pigment that can migrate into the transfer.

Technical Prevention Strategies

To combat bleeding, professional decorators use two primary technical approaches:

| Strategy | Technical Mechanism | Best Use Case |

| Low-Temp Application | Using foils that activate at 120°C – 130°C. Since dye migration typically triggers at higher temperatures (150°C+), staying low prevents the reaction. | Standard polyester t-shirts and performance wear. |

| Sublibloc / Blockout | These foils contain an extra “activated carbon” or “sublistop” layer that acts as a physical barrier to trap migrating gases. | Softshell jackets, sublimated jerseys, and thick fleece. |

| Cooling Speed | Removing the garment from the heat press area and spreading it out to cool quickly reduces the window for gas reaction. | General best practice for all polyester work. |

Frequently Asked Questions

What causes bleeding in heat press transfers?

Bleeding is caused by the dye in polyester fabrics reacting to heat. The dyes turn into a gas and penetrate the heat transfer vinyl (HTV), causing the fabric color to show through the design.

How do I stop my white vinyl from turning pink on red shirts?

To prevent this, use a ‘Blockout’ or ‘Sublibloc’ flex foil. These materials have a built-in barrier layer specifically designed to stop dye migration on polyester garments.

Does washing cause heat transfer bleeding?

No. Bleeding is a heat-triggered chemical reaction, not a laundry issue. It is caused by the temperature of the heat press and the nature of the polyester fabric.