High Tack refers to a high level of initial adhesive strength or “stickiness” between a substrate and its carrier or an application medium. In the garment decoration and signage industries, it specifically describes the bond between Flex Foil (HTV) and its PET carrier, or the aggressive grab of an Application Tape.

Read more

Why It Matters: Impact and Use

Selecting a material with High Tack is a strategic technical choice that directly affects production speed and quality control. In a professional workflow, understanding tack levels is a key component of E-E-A-T (Expertise, Authoritativeness, and Trustworthiness), as it determines the feasibility of complex designs.

- The Trade-Off: While High Tack preserves detail, it requires more physical force to “weed” or “peel.” If the tack is too high for a large, solid design, it can lead to user fatigue or even slight stretching of the vinyl if not handled carefully.

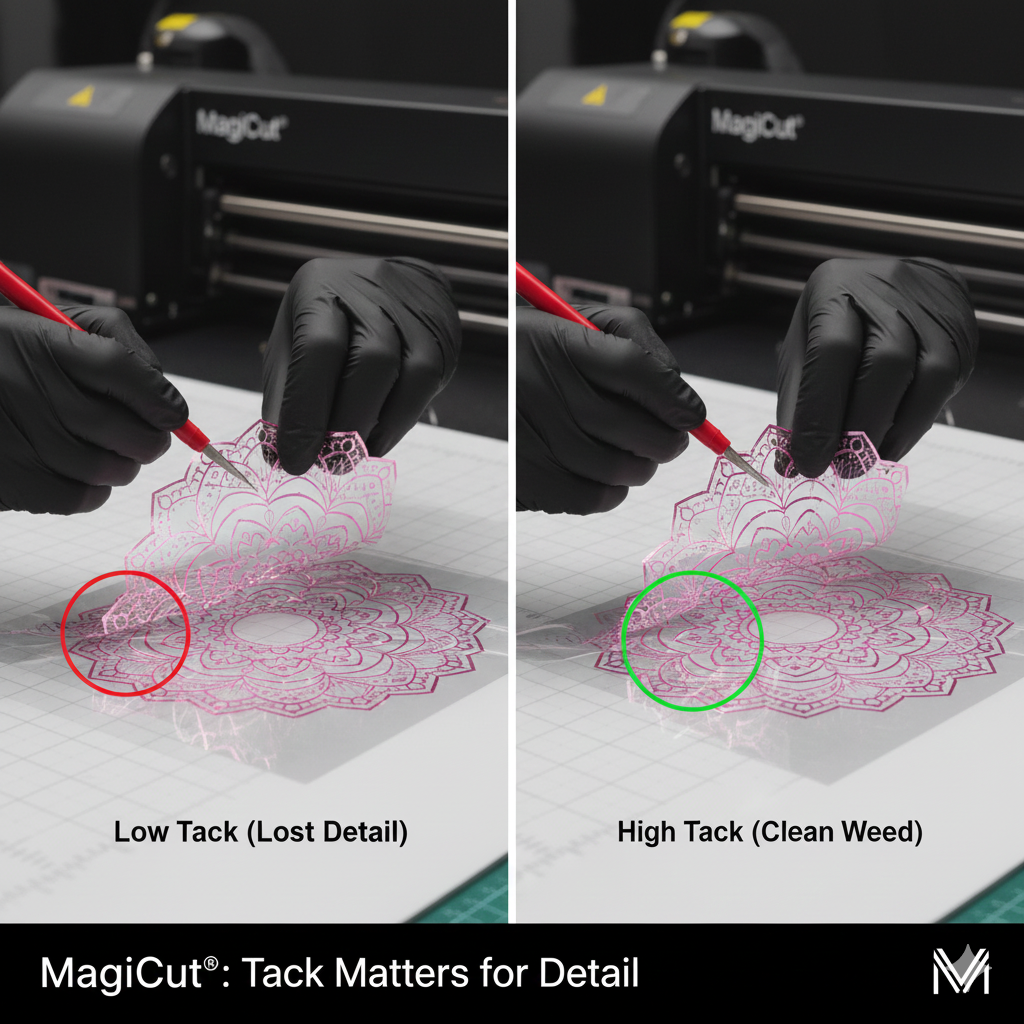

- Detail Retention During Weeding: High Tack is essential for “fine-line” graphics or small text. Because the vinyl adheres more strongly to the backing, intricate pieces are less likely to be accidentally “lifted” or pulled away while removing the excess material (weeding).

- Application Tape Reliability: For sign vinyl or multi-layer transfers, High Tack application tape is used to ensure that heavy or textured films are successfully lifted from their original liner without sliding or dropping.

- Complex Multi-Layering: When stacking different types of Flex Foil, a High Tack carrier allows for more aggressive handling of the garment between presses without the risk of the design shifting.

All High Tack Application Tapes

Comparison: Tack Levels in Flex Foil

| Tack Level | Adhesive Strength | Best Use Case | Benefit |

| Low Tack | Weak / Easy Release | Large blocks of color, simple shapes. | Effortless, fast weeding of large areas. |

| Medium Tack | Standard Balance | General logos, standard-sized text. | The “all-rounder” for most apparel jobs. |

| High Tack | Strong / Aggressive | Micro-text, intricate mandalas, fine lines. | Prevents loss of detail during the weeding process. |

Frequently Asked Questions

When should I choose a High Tack Flex Foil?

Choose High Tack when your design contains very small details, thin lines (under 1mm), or intricate fonts. The stronger adhesive on the carrier film ensures these tiny pieces don’t get pulled up during the weeding process.

Can High Tack adhesive make weeding more difficult?

Yes. Because the bond is stronger, you will need to apply more force to pull the unwanted vinyl away from the backing. For large, simple designs, a Medium or Low Tack foil is usually preferred to save time and reduce effort.

Does High Tack affect how the vinyl sticks to the shirt?

No. ‘Tack’ refers to the bond between the vinyl and its plastic carrier sheet, not the heat-activated adhesive on the back of the vinyl. The wash-fastness and garment adhesion are determined by the hotmelt layer and the heat press settings.