Low Tack refers to a light level of initial adhesive strength between a material and its substrate or carrier. In the context of Heat Transfer Vinyl (HTV) and Application Tape, it describes a “quick-release” property where the bond is strong enough to hold the material in place during storage, but weak enough to allow for effortless removal during the production process.

Read more

Why It Matters: Impact and Use

Choosing a Low Tack material is a strategic decision often made to increase production speed and reduce physical strain. Demonstrating knowledge of when to use Low Tack vs. High Tack is a key indicator of E-E-A-T (Expertise, Authoritativeness, and Trustworthiness) in professional garment decoration.

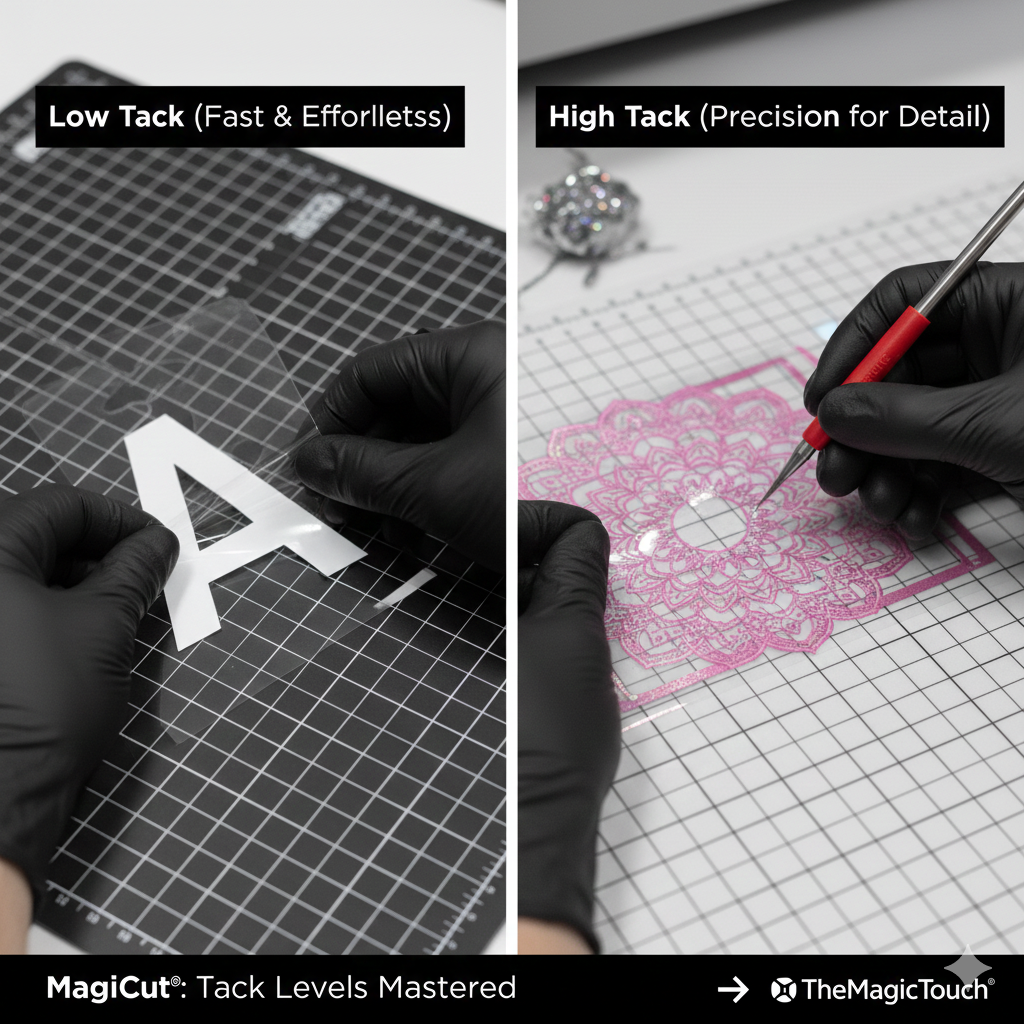

- The Technical Trade-off: The primary disadvantage of Low Tack is “lifting.” If a design has extremely fine lines or micro-details, the plotter blade or the weeding tool may accidentally pull these pieces off a Low Tack carrier. In those specific cases, a High Tack carrier would be the professional recommendation.

- Speed of Weeding: For designs with large, solid shapes or thick fonts, a Low Tack carrier is superior. It allows the user to “peel” away excess vinyl with minimal resistance, significantly reducing the time spent per garment.

- Application Tape Release: When using application tape for wall decals or sign vinyl, a Low Tack tape is essential for delicate surfaces (like painted drywall). It ensures the vinyl stays on the wall while the tape pulls away without damaging the paint or lifting the design.

- Reduced Material Distortion: Because Low Tack requires less force to remove, there is a lower risk of stretching the vinyl during the weeding process. This is particularly important for thin, “soft-flex” foils.

All clamshell Heat Presses

Comparison: Tack Levels in Garment Production

| Tack Level | Adhesive Strength | Best Use Case | Primary Benefit |

| Low Tack | Light / Easy Release | Large numbers, block letters, simple shapes. | High-speed production; easy on the hands. |

| Medium Tack | Standard | General-purpose logos and medium text. | The industry standard “all-rounder.” |

| High Tack | Strong / Aggressive | Script fonts, intricate details, fine lines. | Prevents small details from falling off. |

Frequently Asked Questions

When should I use Low Tack Application Tape?

Low Tack tape is best used for large graphics and delicate surfaces. It is ideal when you need to apply vinyl to a surface where the bond of the vinyl is only slightly stronger than the bond of the tape, such as on matte-painted walls.

Can Low Tack vinyl fall off the shirt after washing?

No. The term ‘Low Tack’ refers only to the adhesive on the carrier sheet that holds the vinyl before it is pressed. The permanent bond to the garment is created by the heat-activated ‘Hotmelt’ layer, which is independent of the tack level.

Is Low Tack better for beginners?

Low Tack is often easier for beginners because ‘weeding’ (removing the waste vinyl) requires much less physical effort. However, if the beginner is working on very intricate designs, a Medium or High Tack might be less frustrating as it holds small pieces in place better.