Migration (also known as Dye Migration or Bleeding) is the unwanted movement of fabric dyes into a heat-applied transfer or ink. This phenomenon occurs when the heat from a press causes the synthetic dyes in a garment (primarily polyester) to turn into a gas—a process called sublimation—which then penetrates the transfer adhesive and tints the final design.

Read more

Why It Matters

Migration is one of the most common “fail points” in professional garment decoration. Understanding how to combat it is essential and ensuring customer satisfaction with high-performance apparel.

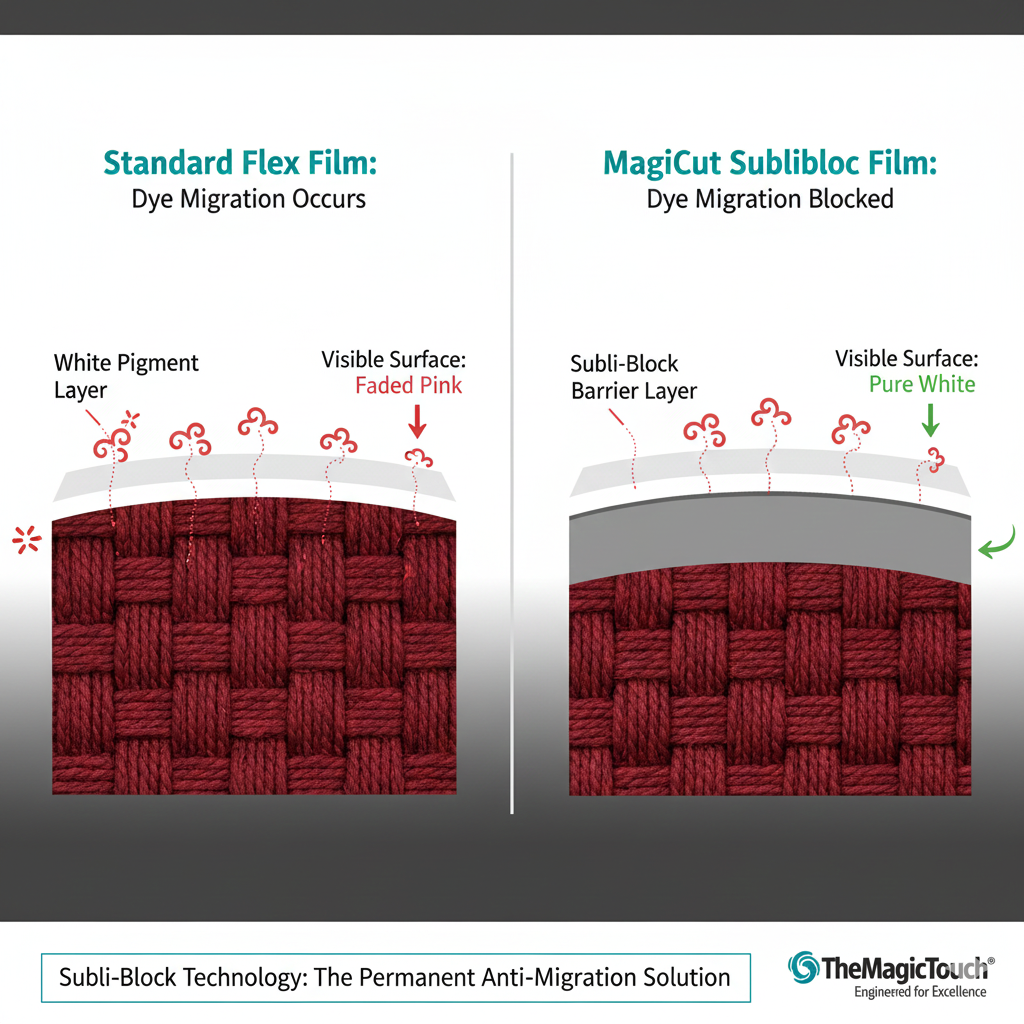

- Subli-Block Barriers: Utilizing specialized films like MagiCut Sublibloc, which feature an activated carbon or silver-pigment layer. This “shield” physically traps the migrating dye before it reaches the surface of the design.

- Color Distortion: The most frequent symptom of migration is a “color shift.” For example, a white logo applied to a red polyester football jersey may turn pink over time as the red dye seeps through the white vinyl.

- Delayed Reaction: Migration doesn’t always happen immediately. It can occur 24 to 48 hours after pressing or even after the first wash, making it a “hidden” quality control issue that can lead to costly returns.

- Fabric Limitations: Polyester and sublimated fabrics (like camouflage patterns or bright “safety” colors) are at the highest risk. The dyes used in these fabrics are designed to be heat-active, making them highly unstable when exposed to standard transfer temperatures.

- Technological Solutions: To prevent this, professionals use two primary strategies:

- Low-Temperature Transfers: Using materials like MagiCut 123Premium Ultra, which apply at temperatures below the dye-activation threshold (usually below 130°C).

- Subli-Block Barriers: Utilizing specialized films like MagiCut Sublibloc, which feature an activated carbon or silver-pigment layer. This “shield” physically traps the migrating dye before it reaches the surface of the design.

All clamshell Heat Presses

Migration Prevention Checklist

| Strategy | Technical Method | Best For |

| Lower Temperature | Pressing at 120°C–130°C. | Lightly dyed polyesters and blends. |

| Subli-Block Film | Using a “Block-Out” barrier layer. | Dark polyester, camo prints, softshells. |

| Shortened Time | Reducing dwell time to the minimum. | Standard sportswear with stable dyes. |

| Cooling Speed | A quick removal of the garment from the heat press and rapid colling down reduces the window for gas reaction. | General best practice for all polyester garments. |

Frequently Asked Questions

Why did my white vinyl turn the color of the shirt?

This is called Dye Migration. The heat from your press turned the shirt’s polyester dye into a gas, which traveled through the vinyl. To prevent this, you should use a ‘Subli-Block’ vinyl or a low-temperature application foil.

At what temperature does dye migration usually start?

Migration typically begins when the fabric is heated above 135°C (275°F). Using transfers that bond at 120°C-130°C is the most effective way to avoid activating the fabric dyes.

Can I stop migration once it has already happened?

Unfortunately, no. Once the dye has migrated into the transfer, it is permanently bonded. The only solution is to replace the garment and use a migration-resistant transfer material for the next print.