Multicolor (or Multi-colored) refers to the process of creating a design using two or more different colors of Flex Foil (HTV). This is achieved by either layering (stacking one color directly on top of another) or inlaying (fitting colors together like a puzzle so each piece touches the fabric directly).

Read more

Why It Matters: Impact and Use

Mastering multicolor applications is a vital skill for high-end custom apparel. Providing technical guidance on layering vs. inlaying demonstrates E-E-A-T (Expertise, Authoritativeness, and Trustworthiness) by ensuring the finished garment is both visually striking and durable through industrial wash cycles.

- Design Complexity: Multicolor designs significantly increase the perceived value of a garment, allowing decorators to charge a premium for complex, multi-tonal logos compared to single-color prints.

- The Layering Challenge: While stacking colors is the fastest way to create a multicolor design, not all Flex foils are compatible. Some materials, such as Glitter, Flocked, or Metallic foils, have textured or chemically treated surfaces that prevent a second layer from adhering properly. Always check the technical data sheet to confirm if a product is “layerable.”

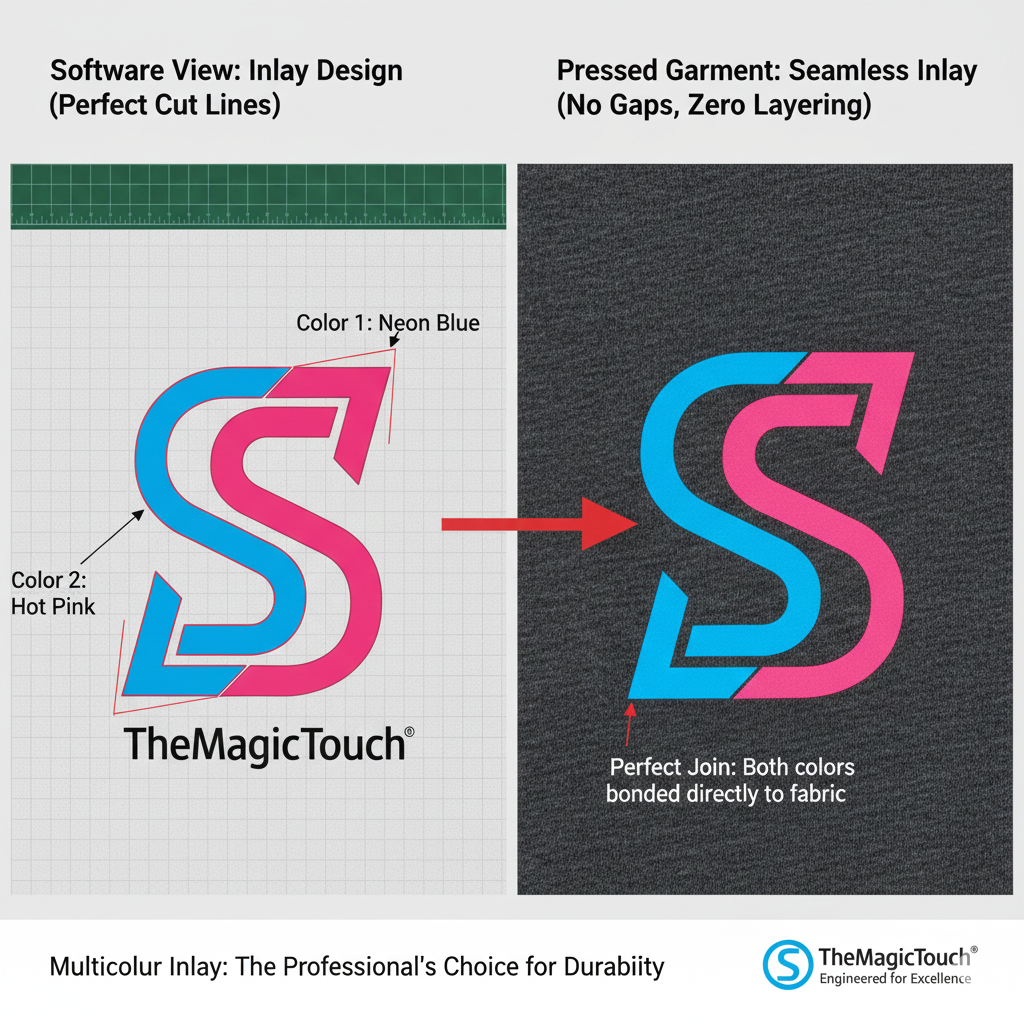

- Inlaying for Durability: To ensure maximum longevity, professionals often use the “inlay” method. By cutting the design so that each color fits perfectly into the gaps of the other, every piece of foil bonds directly to the textile fibers. This creates a thinner, more flexible “hand-feel” and eliminates the risk of top layers peeling off.

- Heat Sensitivity and Shrinkage: When working with multiple colors, each successive heat press cycle can cause the fabric or the first layer of foil to shrink slightly. This can lead to small gaps between colors. Using a Low-Temperature Flex or a “one-second tack” method can help maintain perfect registration.

All clamshell Heat Presses

Comparison: Layering vs. Inlaying

| Feature | Layering (Stacking) | Inlaying (Puzzle-fit) |

| Ease of Setup | High; easy to align. | Medium; requires precise cutting. |

| Thickness | Thicker; can feel heavy. | Thin; feels integrated into the fabric. |

| Durability | Dependent on foil-to-foil bond. | Maximum; all foil bonds to fabric. |

| Material Choice | Limited (no layering on Glitter/Flock). | Unlimited; any foil type can be used. |

Frequently Asked Questions

Can I layer Glitter Flex on top of Standard Flex?

Yes, you can generally layer Glitter on top of a smooth Standard Flex. However, you should never layer Standard Flex (or any other foil) on top of Glitter, as the textured surface prevents a secure bond.

How do I prevent gaps between colors in a multicolor design?

Gaps are usually caused by fabric shrinkage during heating. To prevent this, ‘pre-shrink’ the garment with a 5-second press before applying the first layer. Additionally, adding a 1-2mm ‘bleed’ or overlap in your design software can help cover any slight movement.

What is the ‘Short-Press’ technique for multicolor?

When layering, only press the first layers for 2-3 seconds—just enough to remove the carrier. This prevents over-heating the adhesive. Apply the final full-duration press only once the last color has been positioned.