Nylon is a synthetic polymer, specifically a polyamide, known for its exceptional strength, elasticity, and resistance to abrasion. Historically the primary choice for outerwear and rainwear, it is characterized by its smooth texture and high durability. While often confused with polyester, nylon is more elastic and has a higher moisture absorption rate.

Read more

Why It Matters: Impact and Use

In the garment decoration industry, Nylon is considered a “technical fabric.” Understanding its unique properties is a hallmark, as it requires specialized adhesives and lower heat settings compared to standard cotton or polyester.

Moisture Absorption: Unlike polyester, nylon can absorb small amounts of water. If a nylon garment is damp when pressed, the moisture can turn to steam, creating bubbles under the transfer. Pre-pressing for 2–3 seconds is essential to “de-gas” the fabric.

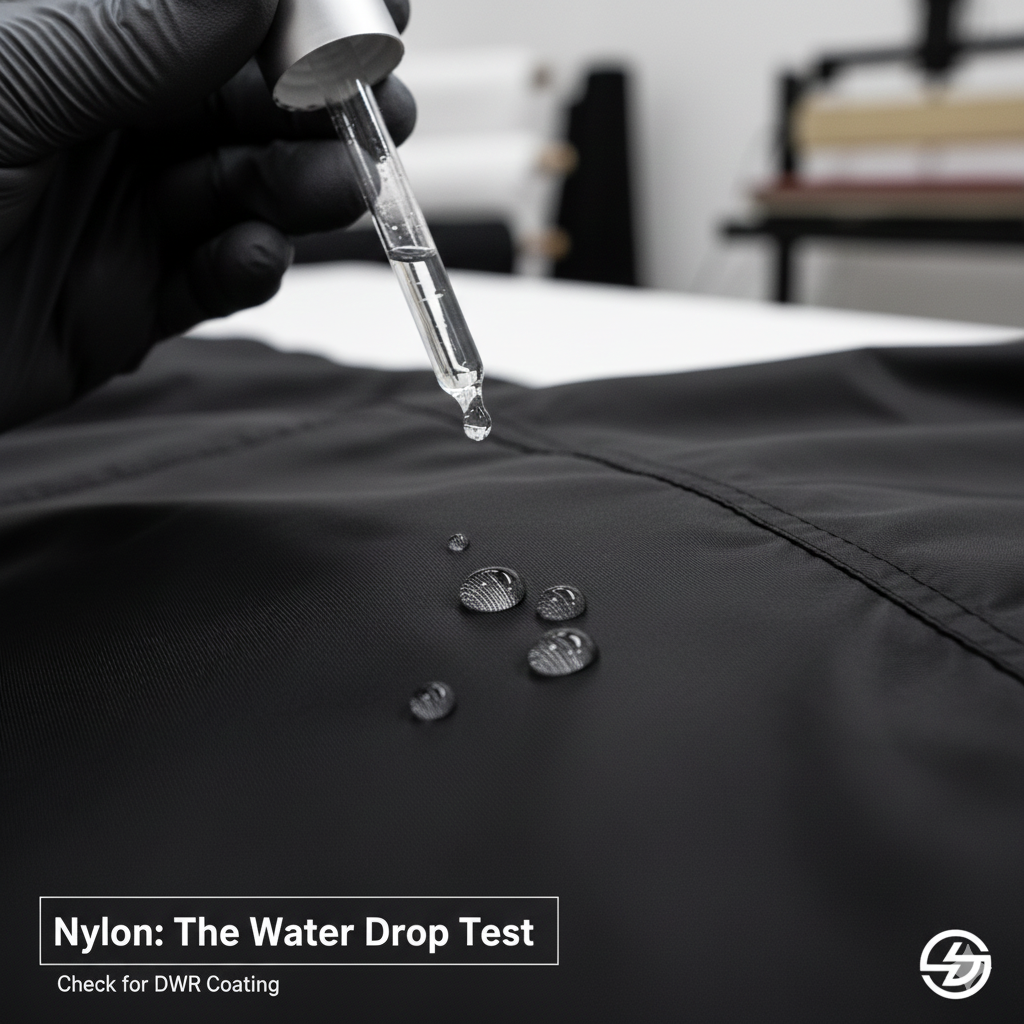

The Adhesion Challenge: Most nylon garments are treated with a DWR (Durable Water Repellent) coating or silicone impregnation to enhance water resistance. These coatings act as a “non-stick” surface, making it difficult for standard Heat Transfer Vinyl (HTV) to bond.

Heat Sensitivity: Nylon has a lower melting point than polyester. Excessive heat during the transfer process can cause “scorching” or leave a permanent “shiny” square mark (press mark) on the garment.

Specialized Solutions: To successfully decorate nylon, professionals use low-temperature or “Nylon-specific” adhesives. Products like Nylon Flex or TheMagicTouch WOW Dark (7.8) transfer paper are engineered to bond at lower temperatures (approx. 130°C–150°C), protecting the fabric while penetrating the water-repellent barrier.

All clamshell Heat Presses

Comparison: Nylon vs. Polyester for Decoration

| Property | Nylon (Polyamide) | Polyester |

| Durability | Higher; very resistant to tearing. | High; standard for most apparel. |

| Water Absorption | Higher (Hydrophilic). | Very Low (Hydrophobic). |

| Heat Resistance | Low; prone to scorching. | High; stable at standard temperatures. |

| Best Transfer Type | Nylon specific Flex, TheMagicTouch WOW Dark | Low temp HTV / DTF |

Frequently Asked Questions

Why does my vinyl peel off nylon jackets?

Nylon is often treated with water-repellent coatings (DWR) that prevent standard adhesives from sticking. You must use a specialized ‘Nylon Flex’ or a transfer paper designed for coated fabrics to ensure a permanent bond.

How do I prevent heat marks on nylon?

To avoid scorching nylon, use a low-temperature transfer (130°C-140°C) and TheMagicTouch release paper or protective cover. Reducing the pressure slightly can also help prevent the ‘shiny’ square mark left by the heat platen.

Can I sublimate on nylon?

While you can technically sublimate on some nylon, it is not recommended. Nylon fibers do not open up as effectively as polyester, leading to dull colors and poor wash-fastness. Additionally, the high heat required for sublimation often melts or damages nylon fabric.