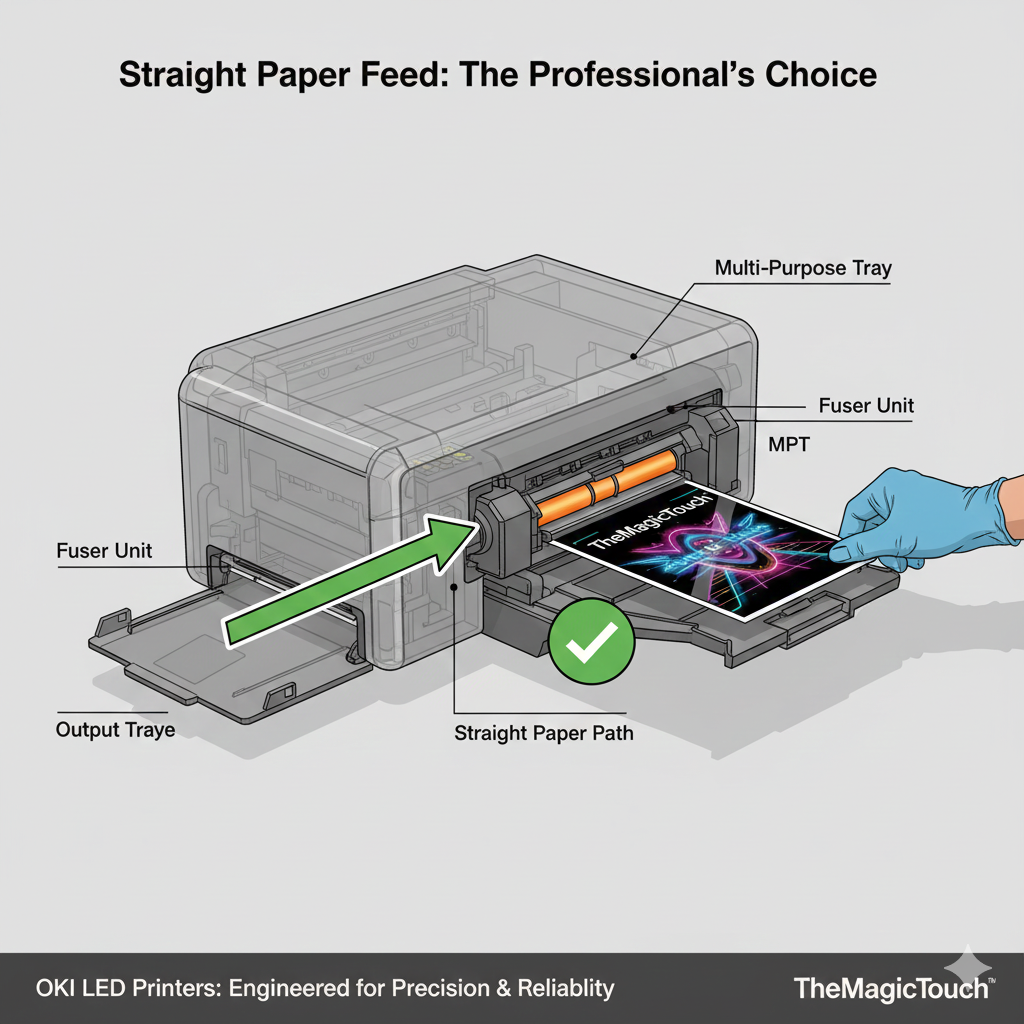

Paper Feed refers to the mechanical system and physical route a sheet of media travels through a printer, from the input tray (source) through the imaging and fuser units to the output tray. In professional transfer printing, the design of the paper feed is categorized as either a U-Path (standard) or a Straight Paper Feed (specialized).

Read more

Why It Matters: Impact and Use

The geometry of a printer’s paper feed is a critical technical factor in successful garment decoration. Understanding the mechanics of a paper path is a clear demonstration of E-E-A-T (Expertise, Authoritativeness, and Trustworthiness), as it directly affects hardware reliability and print accuracy.

- Heavyweight Support: While standard paper feeds are designed for 80gsm office paper, a straight paper feed allows for the use of heavyweight cardstock, labels, and thick transfer foils (up to 300gsm+), significantly expanding the range of products a business can offer.

- Prevention of Jams and Delamination: Transfer papers, such as those from TheMagicTouch, are composed of multiple layers, including a heat-sensitive coating and a carrier. A “U-Path” feed forces the paper to bend 180 degrees; for thick or rigid media, this can cause the coating to crack or the sheet to jam. A Straight Paper Feed minimizes these bends, allowing the media to pass through flat.

- Fuser Consistency: For the toner to bond correctly to transfer media, it must pass through the fuser at a precise, steady speed. A straight feed reduces the mechanical resistance on the paper, ensuring even heat distribution and preventing “wrap-arounds” (where the paper sticks to the fuser rollers).

- Hardware Longevity: Printers like OKI LED models are highly favored in the industry because they feature a “bypass” to a rear exit. This straight-through path reduces wear and tear on the internal pickup rollers and prevents the buildup of adhesive residue inside the machine.

All clamshell Heat Presses

Comparison: Paper Feed Types

| Feed Type | Path Shape | Best For | Risk Factor |

| U-Path | 180° Curve | Standard copy paper, thin flyers. | High risk of jamming with thick transfer paper. |

| L-Path | 90° Curve | Envelopes, medium cardstock. | Moderate stress on rigid coatings. |

| Straight Path | 0° (Flat) | Transfer Paper, Stickers, Cardboard. | Lowest risk; ideal for technical media. |

Frequently Asked Questions

Why is a straight paper feed better for transfer paper?

Transfer paper is thicker and more rigid than regular paper. A straight paper feed allows the media to pass through the printer without bending, which prevents the heat-sensitive coating from cracking or peeling off inside the fuser.

Which printers offer a straight paper feed?

OKI LED printers are the industry standard for this feature. They typically allow you to open a rear exit tray, which enables the paper to travel in a straight line from the Multi-Purpose Tray through the back of the printer.

Can a bad paper feed affect print alignment?

Yes. In U-path printers, the tension of the rollers as they pull the paper around a curve can cause ‘skewing.’ A straight path provides more consistent tension, which is vital for precise alignment in multi-step transfer processes.