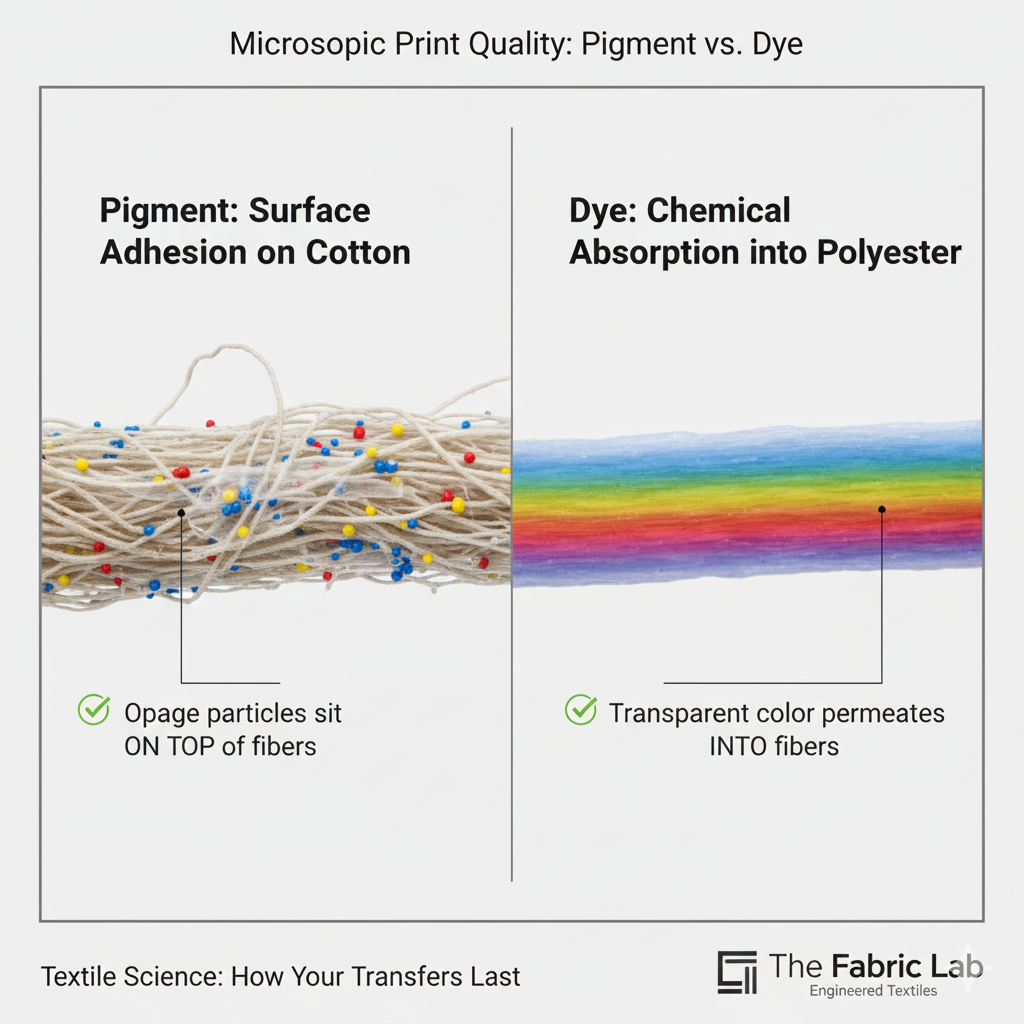

A Pigment is a finely ground, solid coloring substance that is insoluble in the liquid or medium in which it is dispersed. Unlike dyes, which dissolve and chemically bond with fibers, pigments are microscopic particles that sit on the surface of a material, held in place by a binder or fused via heat. In digital printing, Toner used in LED and Laser printers is essentially a dry, powdered form of pigment encapsulated in plastic resin.

Read more

Why It Matters: Impact and Use

Understanding the difference between pigments and dyes is fundamental to achieving professional-grade garment decoration. This technical knowledge is a key component of E-E-A-T (Expertise, Authoritativeness, and Trustworthiness), as it dictates the washability, opacity, and color vibrance of the finished product.

- Color Consistency: Pigments offer a wide color gamut and highly predictable results. In LED printing, the precise placement of toner particles ensures sharp edges and fine detail that are difficult to achieve with liquid dyes that might “bleed” into the fabric.

- Surface Adhesion vs. Absorption: Because pigments remain on the surface of the fabric fibers rather than soaking in, they provide excellent Opacity. This makes pigment-based systems (like LED Toner or DTF inks) ideal for printing on dark garments where the design needs to “sit” on top of the fabric to remain visible.

- UV and Fade Resistance: Pigment particles are naturally more stable than dye molecules. This results in superior lightfastness, meaning designs are less likely to fade when exposed to sunlight, making them perfect for workwear and outdoor apparel.

- Durability and Hand-Feel: Since the pigment is fused to the surface using a polymer binder (in the case of transfer paper), the “hand-feel” (texture) is more noticeable than sublimation. However, the mechanical bond created by heat and pressure ensures that the print remains durable through numerous wash cycles.

Comparison: Pigment vs. Dye

| Feature | Pigment (Toner/DTF) | Dye (Sublimation) |

| Location | Sits on top of the fiber. | Absorbed into the fiber. |

| Best Substrate | Cotton, Polyesters, Blends, Dark fabrics. | Light-colored 100% Polyester. |

| Opacity | High (Excellent for dark colors). | Low (Transparent). |

| Feel | Slightly textured (the “hand”). | Zero feel (integrated into fabric). |

| Fade Resistance | Excellent (High UV stability). | Good, but sensitive to extreme UV. |

Frequently Asked Questions

Why are pigments better for dark shirts than dyes?

Pigments are opaque and sit on top of the fabric fibers. Because they do not soak in, they can effectively cover the dark color of the shirt. Dyes are transparent and would be ‘lost’ or muddied by the dark background of the fabric.

Is toner considered a pigment?

Yes. Toner used in LED and Laser printers is a dry mixture of plastic resins and pigment particles. When heated in a fuser or heat press, the resin melts, acting as a binder that locks the pigment onto the surface of the transfer paper or garment.

Do pigment prints crack over time?

If the pigment is applied using high-quality transfer paper and the correct heat/pressure settings, it should remain flexible. Cracking usually occurs if the pressure was too light during the transfer or if the garment is washed at temperatures exceeding the manufacturer’s recommendation.