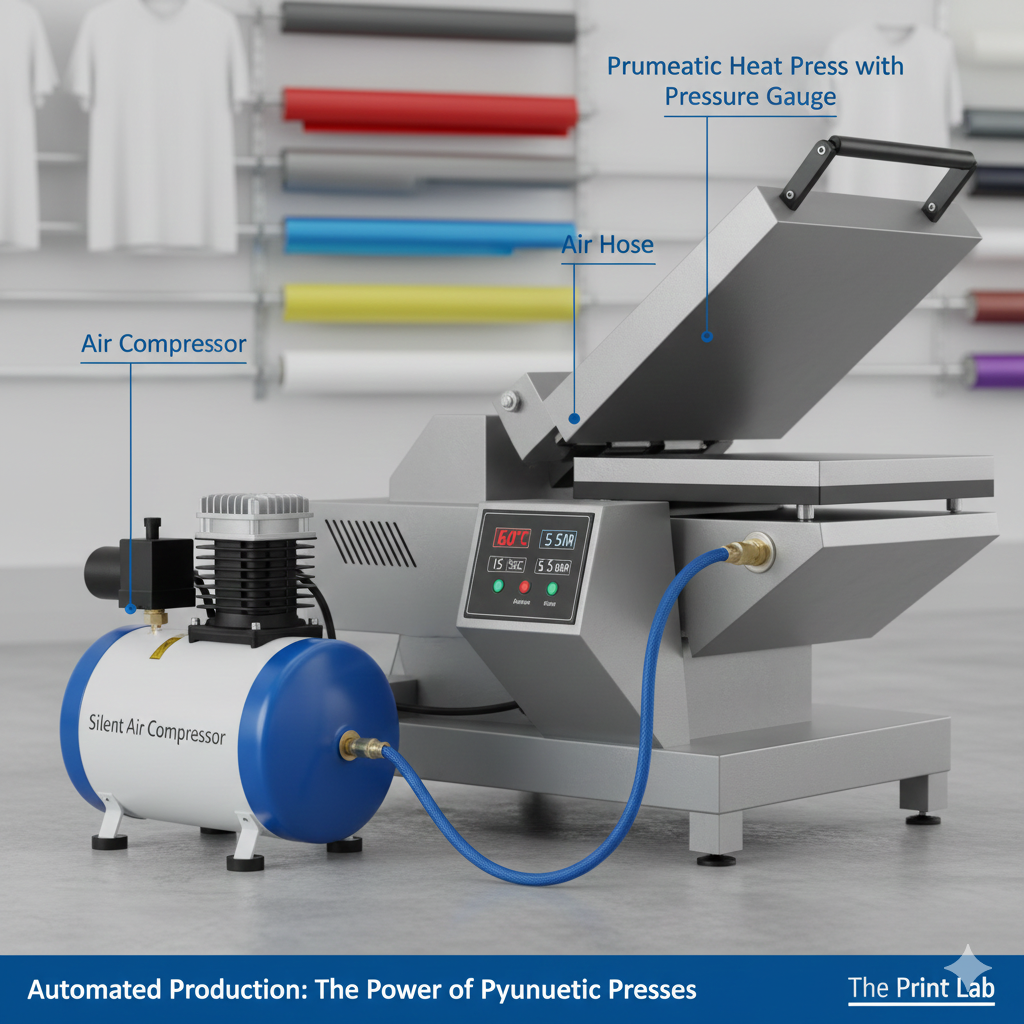

Pneumatic refers to a system that uses compressed air to transmit and control power. In the printing industry, a Pneumatic Heat Press (such as the Insta HTP728) is an automated machine that utilizes an air cylinder to close the heat platen and apply pressure. This system requires an external Air Compressor to provide the necessary force, replacing the manual lever-and-arm effort required by traditional presses.

Read more

Why It Matters: Impact and Use

For high-volume production facilities, switching to pneumatic technology is a strategic move by ensuring industrial-grade consistency and operator safety.

- Automatic Opening: Most pneumatic machines are “auto-open,” meaning the platen lifts automatically once the timer reaches zero. This prevents scorched garments and allows the operator to prep the next item while the current one is being pressed.

- Precision Pressure Control: Unlike manual presses where pressure is “felt” through resistance, pneumatic presses use a digital or analog Pressure Gauge (PSI/Bars). This allows for exact replication of settings, which is vital for technical transfers like DTF or Screen Print Transfers that require specific, heavy pressure to bond.

- Uniformity Across Large Batches: Manual fatigue often leads to inconsistent pressure toward the end of a shift. A pneumatic press delivers the exact same force on the 1st garment as it does on the 500th, ensuring a 0% failure rate due to under-pressing.

- Ergonomics & Workforce Health: Operating a manual press for 8 hours can lead to repetitive strain injuries. Pneumatic presses usually feature push-button or foot-pedal activation, creating a safer and more efficient working environment.

All clamshell Heat Presses

Comparison: Pneumatic vs. Manual Heat Press

| Feature | Pneumatic Heat Press | Manual Heat Press |

| Pressure Source | Compressed Air (Cylinder) | Physical Muscle Power |

| Consistency | Perfect; measured in PSI/Bars. | Variable; based on operator feel. |

| Production Speed | High (Semi-automatic). | Moderate (Manual). |

| Setup Requirement | Requires an Air Compressor. | Plug-and-play. |

| Best For | High-volume shops & Workwear. | Hobbyists & Low-volume boutiques. |

Frequently Asked Questions

Do I need a special air compressor for a pneumatic heat press?

Most pneumatic presses require a compressor with a tank size of at least 24-50 liters and the ability to maintain 6-8 bars of pressure. For a quieter office environment, a ‘Silent’ compressor is highly recommended.

Can a pneumatic press handle thick items like hoodies?

Yes. Pneumatic presses are excellent for thick items because the air cylinder automatically compensates for the thickness of the substrate to maintain the set pressure, whereas manual presses often need the height adjusted via a knob.

Is a pneumatic heat press faster than a manual one?

While the dwell time (pressing time) is the same, the overall production speed is faster because the operator exerts less energy and the automatic opening allows for a more fluid workflow.