Post-Press is a secondary heat application step performed immediately after the initial transfer and the removal of the carrier sheet. By applying heat and pressure a second time directly to the “naked” design (usually protected by a finishing sheet), the transfer is permanently fused into the textile fibers. This process is essential for Direct To Film (DTF), White Toner Transfer Paper, and various Flex Foils.

Read more

Why It Matters: Impact and Use

In professional garment decoration, the Post-Press is often the difference between a “retail-quality” garment and one that peels after three washes. Implementing this step is a hallmark of E-E-A-T (Expertise, Authoritativeness, and Trustworthiness), ensuring the longevity and hand-feel of the finished product.

- The T.Seal Advantage: For cotton garments, specialized finishing sheets like TheMagicTouch T.Seal use a soft silicone coating to “lock” the transfer into the pores of the cotton. This not only increases durability but also makes the print stretchier and more breathable.

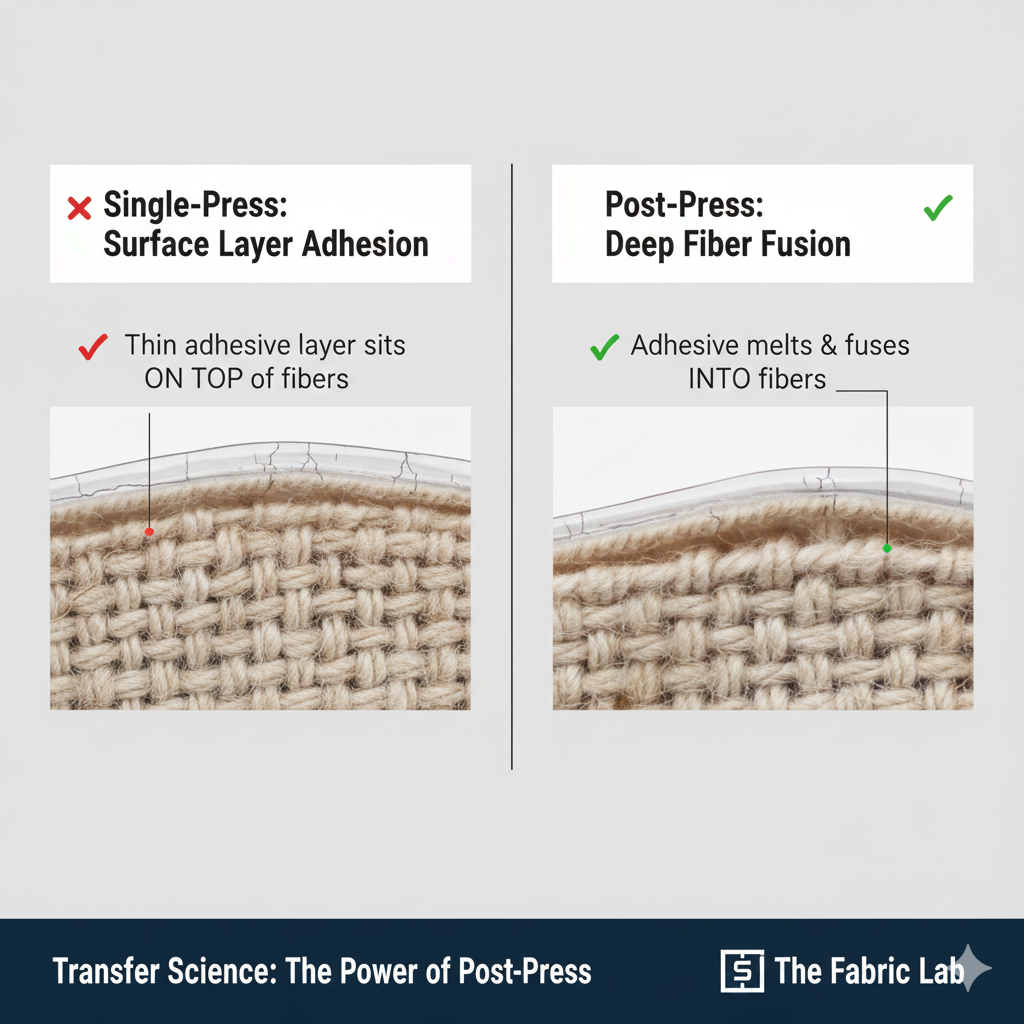

- Maximum Washability: The initial press bonds the adhesive to the surface. The Post-Press “liquefies” the adhesive again, forcing it deeper into the “valleys” of the fabric weave. This mechanical lock is what prevents cracking and peeling during high-temperature laundry cycles.

- Surface Texture & Finish: Depending on the protective sheet used, a Post-Press can change the aesthetic of the print. A Teflon sheet creates a glossy finish, while Parchment or Silicone paper creates a professional matte look that reduces the “plastic” appearance of the transfer.

- Improved “Hand-Feel”: By flattening the transfer into the garment, the design feels thinner and more integrated into the fabric, rather than sitting like a thick layer on top. This is a key metric for customer satisfaction and high CTR (Click-Through Rate) on product reviews.

All clamshell Heat Presses

Comparison: Initial Press vs. Post-Press

| Feature | Initial Press | Post-Press (Finishing) |

| Primary Goal | Bond transfer to garment surface. | Deep fiber fusion and texture finishing. |

| Carrier Sheet | Present (Plastic or Paper). | Removed (Design is exposed). |

| Protection | Carrier protects the design. | Must use Teflon, Silicone, or T.Seal. |

| Duration | 10–30 seconds (Standard). | 5–10 seconds (Quick set). |

Frequently Asked Questions

Is a post-press mandatory for DTF transfers?

While not strictly ‘mandatory’ to see the image, it is highly recommended for commercial durability. A post-press ensures the DTF adhesive is fully embedded in the fabric, which significantly increases the wash-fastness and prevents the edges from lifting.

What happens if I don’t use a cover sheet during post-press?

If you do not use a protective sheet (like Teflon or Silicone paper), the exposed transfer ink or vinyl will melt and stick directly to the top platen of your heat press. This can ruin the garment and require a difficult cleanup of the heat press.

Can I use post-pressing to fix a design that is starting to peel?

Yes, often. If a transfer is lifting because it wasn’t pressed correctly the first time, you can sometimes ‘save’ the garment by performing a heavy-pressure post-press with a finishing sheet to re-melt the adhesive into the fibers.