A Powder Shaker is a specialized machine used in the Direct to Film (DTF) printing workflow to apply TPU (Thermoplastic Polyurethane) adhesive powder to a wet-ink film. Its primary function is to distribute the powder evenly across the printed design, shake off the excess from the unprinted areas, and (in automatic models) heat the film to “cure” or melt the powder into a tacky, solid layer.

Read more

Why It Matters: Impact and Use

In the DTF industry, the powder shaker is the engine of high-volume production. Mastering the “powdering” stage is a critical marker of E-E-A-T (Expertise, Authoritativeness, and Trustworthiness), as the consistency of the adhesive layer determines the stretch, durability, and wash-fastness of the final garment.

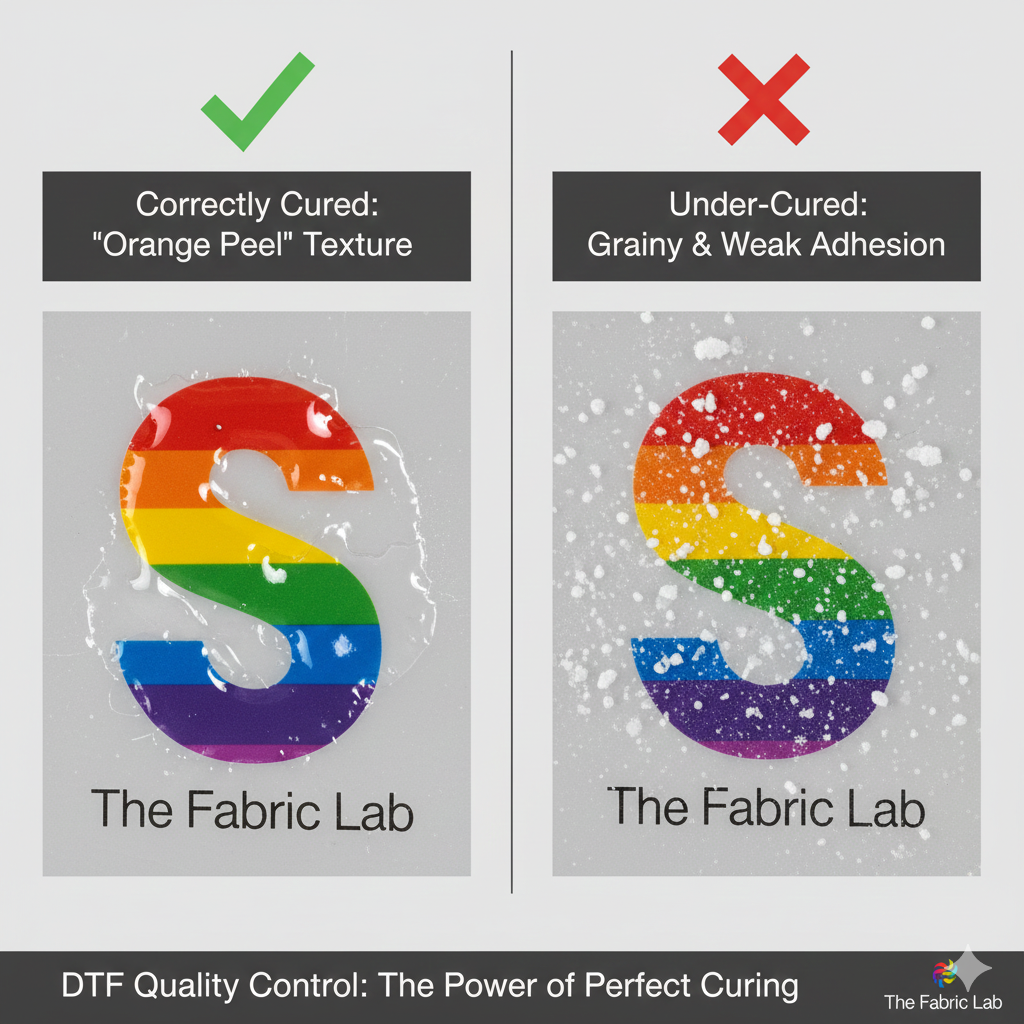

- Curing Control: The integrated heating tunnel in a shaker-dryer must maintain a precise temperature (usually 110°C–150°C). Under-curing leaves the powder grainy; over-curing can make the film brittle or oily (the “migrating plasticizer” effect).

- The Bonding Agent: Without the powder, DTF ink has no way to adhere to fabric. The shaker ensures that every pixel of wet ink is “grabbed” by the adhesive, creating a uniform glue layer that prevents “pinholes” or weak spots in the transfer.

- Manual vs. Automatic Workflows: * Manual Shakers: Used by boutique shops, these require the operator to manually dust the film and use a separate DTF Curing Oven.

- Automatic Shaker-Dryers: Designed for industrial use, these units connect directly to the DTF printer. They automate the entire process—powdering, vibrating (to remove excess), curing, and rewinding the finished roll—dramatically increasing ROI (Return on Investment) through labor savings.

- Consistency & Precision: Automatic shakers use a “weighted” vibration system. If the excess powder isn’t removed perfectly from the clear parts of the film, “speckling” occurs on the garment. A high-quality shaker ensures a clean “no-weed” result.

All clamshell Heat Presses

Comparison: Manual vs. Automatic DTF Powdering

| Feature | Manual Process | Automatic Powder Shaker |

| Production Scale | Low (Single sheets/small batches). | High (Continuous roll-to-roll). |

| Consistency | Variable; depends on manual shaking. | Precise; mechanical vibration. |

| Curing Method | External Oven or Heat Press. | Integrated Infrared/Fan Oven. |

| Space Requirement | Small (Desktop). | Significant (Floor-standing unit). |

| Labor Intensity | High; requires constant attention. | Low; fully automated “set and forget.” |

Frequently Asked Questions

Why do I need to shake the powder off the DTF film?

The powder only needs to stick to the wet ink. Any excess powder left on the clear areas of the film will transfer to the garment as tiny, unwanted white dots (speckling). An automatic shaker uses vibration to ensure only the design is coated.

What is the ‘melted’ powder supposed to look like?

Once it passes through the shaker’s oven, the powder should have an ‘orange peel’ texture. It should be melted and shiny, not grainy or dry, but it should not be so hot that the film starts to warp or the ink begins to boil.

Is DTF powder hazardous?

DTF adhesive powder is a fine particulate that should not be inhaled. When using a powder shaker—especially an automatic one—it is vital to have proper air filtration or a fume extractor connected to the oven to remove gasses and airborne dust.