A Pressure Roller, often referred to as a Pinch Roller, is a precision-engineered rubber or grit-textured wheel found in cutting plotters and inkjet printers. Its primary function is to exert downward force on the media (vinyl, paper, or film) against the drive roller (or grit shaft). This creates the necessary friction to move the material forward and backward with extreme accuracy during the printing or cutting process.

Read more

Why It Matters: Impact and Use

In the world of signage and garment decoration, the quality and placement of pressure rollers are fundamental to hardware performance. Understanding their role is a key technical indicator of E-E-A-T (Expertise, Authoritativeness, and Trustworthiness), as poor roller management is the leading cause of tracking errors and wasted material.

- Feed Reliability: Without synchronized pressure, the media may slip or skew. This is particularly critical in Print & Cut workflows, where the plotter must align perfectly with pre-printed registration marks.

- Tracking Accuracy: For long “runs” of vinyl cutting (e.g., 3-meter banners), even a fraction of a millimeter of slippage can cause the start and end of a design to misalign. High-quality pressure rollers ensure “true tracking” over long distances.

- Media Stabilization: Pressure rollers prevent the media from “tunneling” or arching in the middle. In wide-format printers, multiple rollers are distributed across the width of the machine to keep the material perfectly flat against the print bed, preventing costly head strikes.

- Adjustable Tension: Professional plotters allow users to adjust the “force” of individual rollers. For example, inner rollers may be set to a lighter tension to prevent leaving “track marks” on sensitive media like thin heat transfer vinyl (HTV) or soft window films.

All clamshell Heat Presses

Comparison: Roller Requirements by Machine Size

| Machine Type | Typical Roller Count | Primary Function |

| Desktop Plotter (e.g., Cameo) | 2 Rollers | Basic hobby-grade media feeding. |

| Professional Plotter (60cm) | 2 – 3 Rollers | Precision tracking for garment vinyl. |

| Wide-Format Printer (160cm) | 10 – 15+ Rollers | Keeping heavy rolls flat and tensioned. |

| Flatbed Cutter | Vacuum System | Replaces rollers to avoid any physical marks on media. |

Frequently Asked Questions

Why is my vinyl slipping during cutting?

Slippage is usually caused by dirty or worn pressure rollers. Dust and adhesive residue can build up on the rubber, reducing friction. Clean them regularly with a lint-free cloth and isopropyl alcohol to maintain grip.

Can pressure rollers leave marks on my transfers?

Yes, especially on ‘soft’ materials like flock or thin HTV. To prevent this, ensure the rollers are placed only over the ‘waste’ areas of the vinyl or reduce the downward pressure setting if your machine allows it.

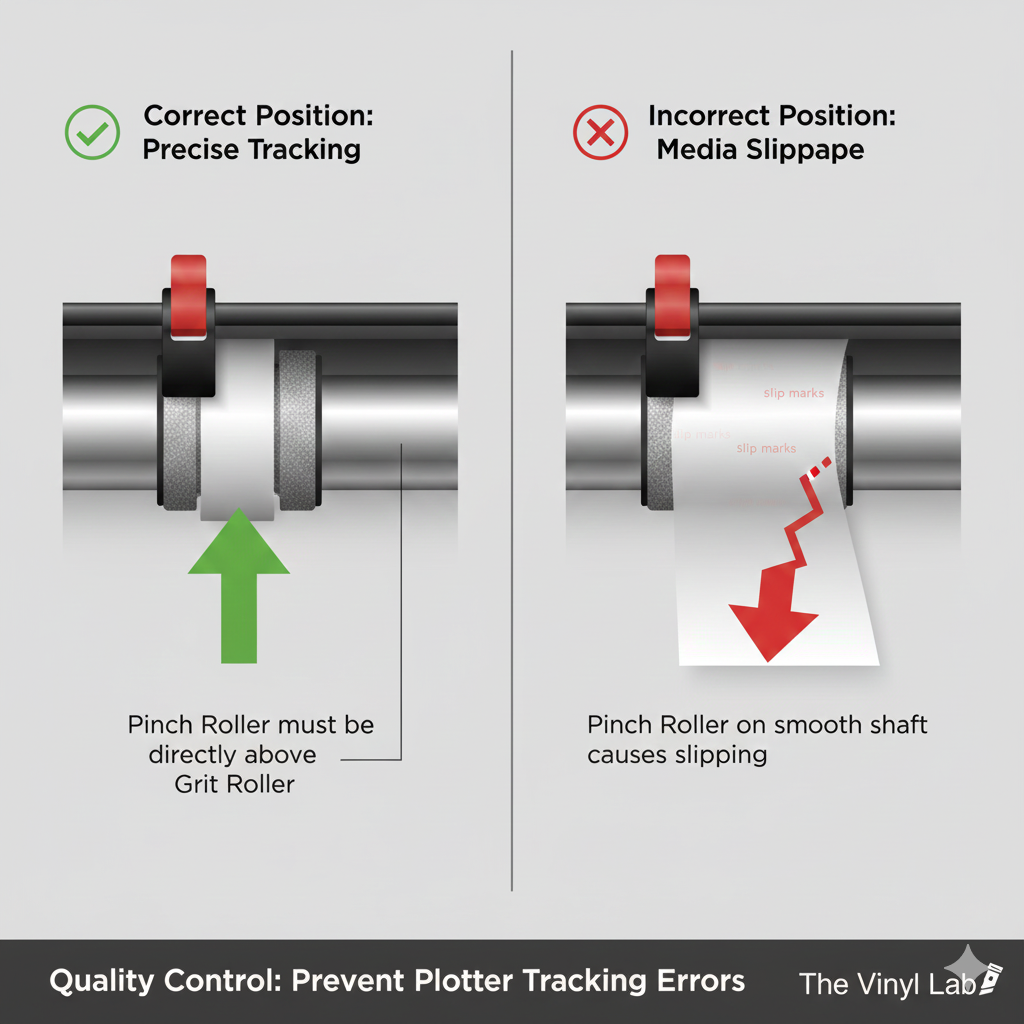

Where should I position my pinch rollers?

Pinch rollers must always be positioned directly over the grit rollers (the textured metal sections on the drive shaft). If a roller is placed over a smooth section of the shaft, it will not have the traction to move the media accurately.