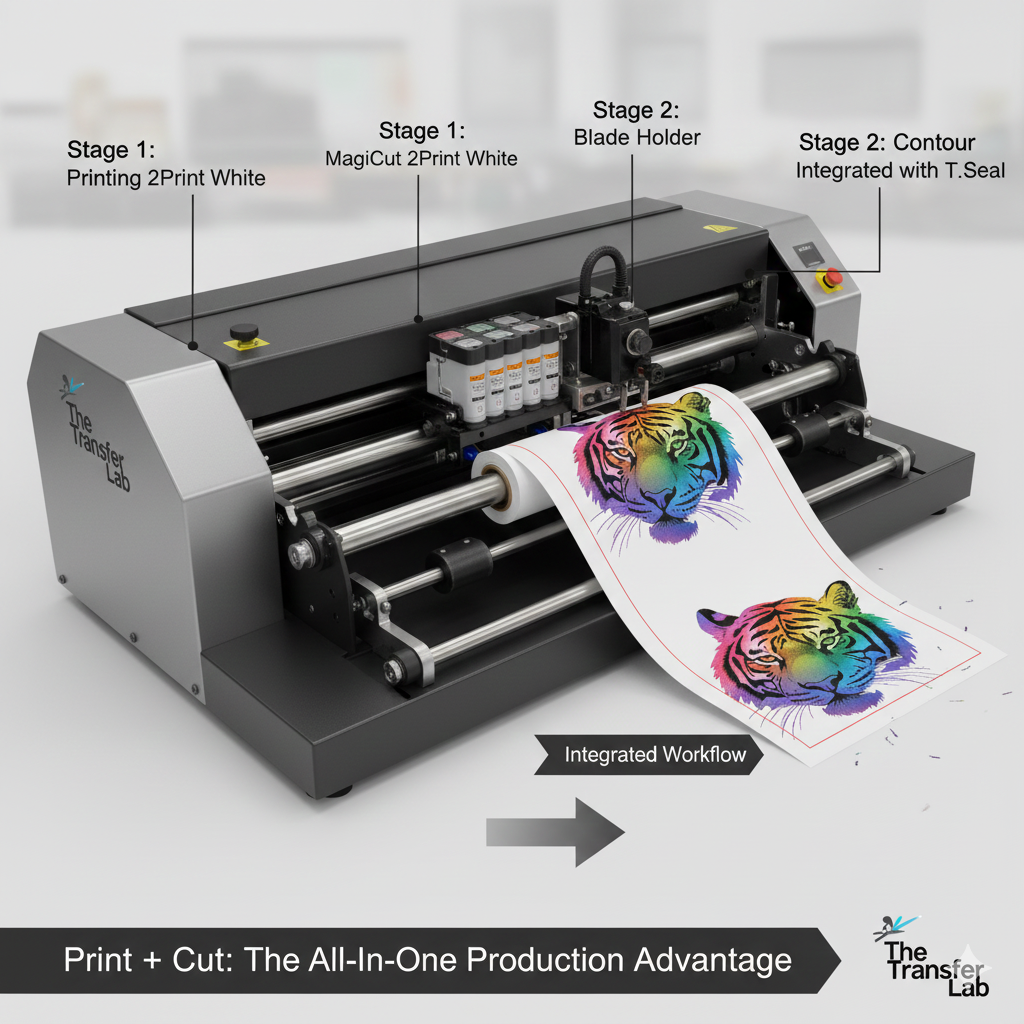

Print + Cut refers to an all-in-one production workflow performed by a single machine capable of both digital inkjet printing and precision contour cutting. Unlike “Print & Cut,” which requires transferring media between two separate devices, a Print + Cut system (such as the Roland VersaSTUDIO BN2-20) performs both tasks sequentially on the same internal drive system without the media ever leaving the machine.

Read more

Why It Matters: Impact and Use

For small-to-medium businesses and custom print shops, Print + Cut technology offers a streamlined, “set-it-and-forget-it” solution. This integrated approach is a key technical differentiator, as it drastically reduces human error and production time.

- Versatile Media Support: This technology is specifically designed for high-performance materials like MagiCut 2Print White printable Heat Transfer Vinyl (HTV), enabling the creation of vibrant, custom-shaped transfers for both light and dark textiles in one sitting.

- No Registration Marks Required: Because the machine knows exactly where it printed the image relative to its own cutting head, you often do not need to print optical registration marks. This saves valuable space on the media, allowing for more designs per meter and increasing your ROI (Return on Investment).

- Seamless Workflow: The machine first prints the design with specialized inks (like Eco-Solvent) and then automatically switches to the cutting blade to trim the contours. This eliminates the risk of misaligning the media when moving it from a printer to a separate plotter.

- Space-Saving Design: Combining two industrial functions into one footprint is ideal for boutique shops or home-based businesses where floor space is at a premium.

All clamshell Heat Presses

Comparison: Print + Cut vs. Print & Cut

| Feature | Print + Cut (Integrated) | Print & Cut (Separate) |

| Equipment | 1 Machine (Printer/Cutter) | 2 Machines (Printer + Plotter) |

| Workflow | Automatic; continuous. | Manual; media must be moved. |

| Registration Marks | Usually unnecessary. | Mandatory for alignment. |

| Media Waste | Lower (no marks needed). | Higher (space needed for marks). |

| Best For | Prototyping, small shops, stickers. | High-speed, high-volume production. |

Frequently Asked Questions

Why is Print + Cut more efficient than using two separate machines?

Print + Cut is more efficient because it eliminates the manual step of moving media from the printer to the cutter. Since the machine tracks the media position internally, it also eliminates the time spent by a plotter’s optical eye searching for registration marks.

Can I use a Print + Cut machine for just printing or just cutting independently?

Yes. Integrated machines offer complete flexibility. You can use the device as a standalone high-quality printer for items like posters or banners, or as a standalone vinyl cutter for simple lettering and pinstriping. This “two-in-one” capability allows you to maximize your workspace and handle a wider variety of jobs with a single footprint.

Is the cutting quality of an integrated machine as good as a standalone plotter?

Yes. Integrated Print + Cut machines use professional-grade servo motors and blades that offer the same precision as standalone cutters, making them perfect for intricate vinyl lettering and contour-cut stickers.