A Printhead is the precision-engineered core component of an inkjet printer responsible for transferring ink onto a substrate. It houses hundreds—sometimes thousands—of microscopic nozzles (nozzle plate) that eject ink droplets in precise patterns. This technology is the foundation of Dye Sublimation, Direct To Film (DTF), Direct To Garment (DTG), and Eco-Solvent printing systems.

Read more

Why It Matters: Impact and Use

In the digital printing industry, the printhead is the most critical and often the most expensive consumable part of the machine. Understanding its maintenance is a primary indicator of E-E-A-T (Expertise, Authoritativeness, and Trustworthiness), as printhead health directly dictates the resolution and color accuracy of the final product.

- Impact on Print Quality: A healthy printhead ensures smooth gradients and sharp text. If even a few nozzles “misfire” (spray at an angle) or “clog” (stop spraying), the color balance of the entire design shifts, leading to customer rejections and wasted media.

- Microscopic Precision: Printheads operate using either Piezoelectric (using electric pulses to squeeze ink) or Thermal (using heat to boil ink) technology. They must fire millions of droplets per second with sub-micron accuracy to achieve high-definition results.

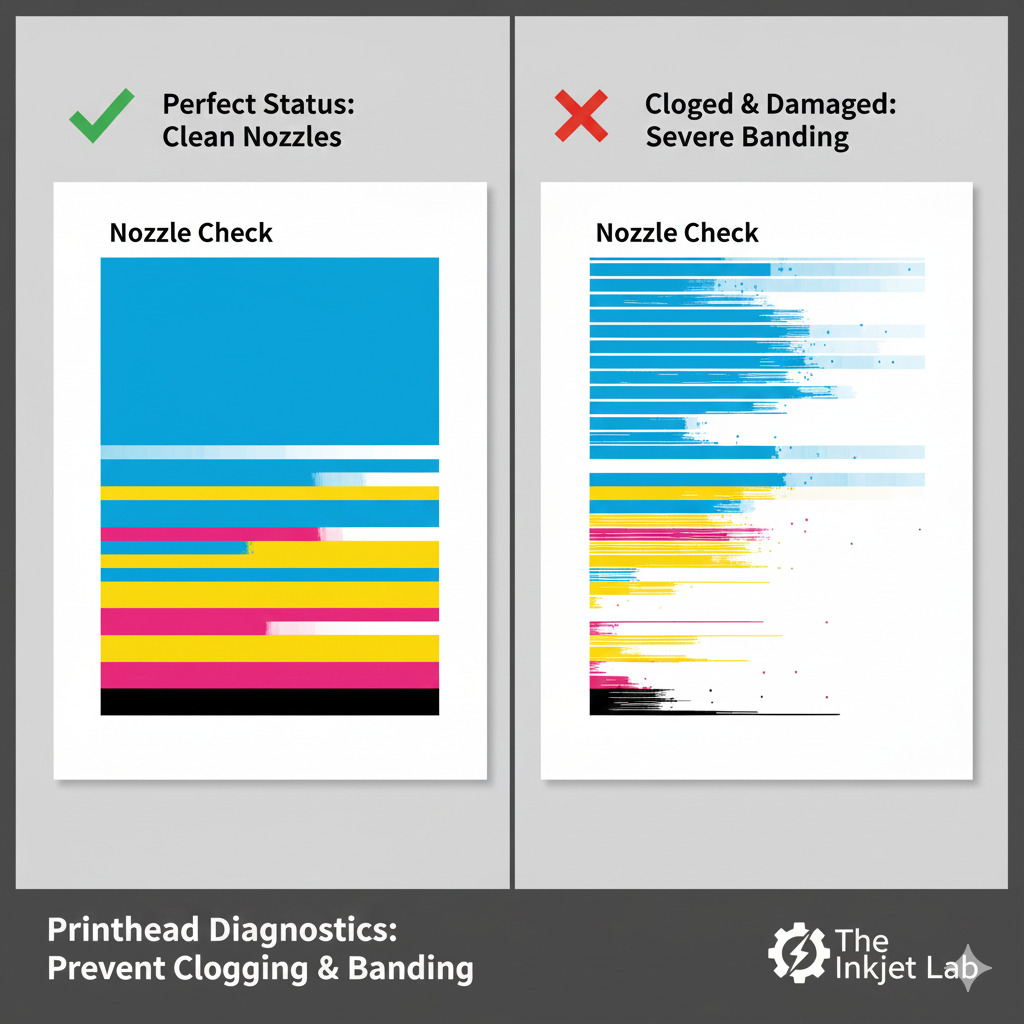

- The “Clogged Nozzle” Risk: Because the nozzle openings are thinner than a human hair, they are highly susceptible to “drying out.” If the printer is left idle, the ink (especially DTF white ink or Sublimation ink) can solidify, leading to Banding—horizontal lines across the print that ruin the output.

- Maintenance & ROI: Regular Nozzle Checks and cleaning cycles are mandatory. For advanced systems like DTF, automated circulation and “wet capping” stations are used to keep the printhead moist. Neglecting these steps can lead to permanent hardware failure, significantly impacting your ROI (Return on Investment).

All clamshell Heat Presses

Printhead Maintenance Checklist

| Action | Frequency | Purpose |

| Nozzle Check | Daily (before production) | To identify missing or misfiring nozzles. |

| Cleaning Cycle | As needed | Uses internal pumps to flush dried ink. |

| Manual Cleaning | Weekly / Monthly | Cleaning the “wiper blade” and “capping station” around the head. |

| Ink Circulation | Constant (Automatic) | Essential for DTF white ink to prevent pigment settling. |

Frequently Asked Questions

What causes a printhead to clog?

The most common causes are inactivity, low humidity, and air bubbles. If ink is left sitting in the nozzles without movement, the carrier liquid evaporates, leaving behind solid pigment particles that block the flow.

Can a clogged printhead be fixed?

Most minor clogs can be cleared using the printer’s internal cleaning utility or a specialized cleaning solution. However, if the ink has dried completely inside the head (deflection), it may require professional ultrasonic cleaning or a full replacement.

How long does a professional printhead last?

With perfect maintenance, a piezoelectric printhead (like those in Epson or Roland machines) can last several years. However, in high-production DTF environments, they are often considered high-wear parts that may need replacement every 12-24 months.