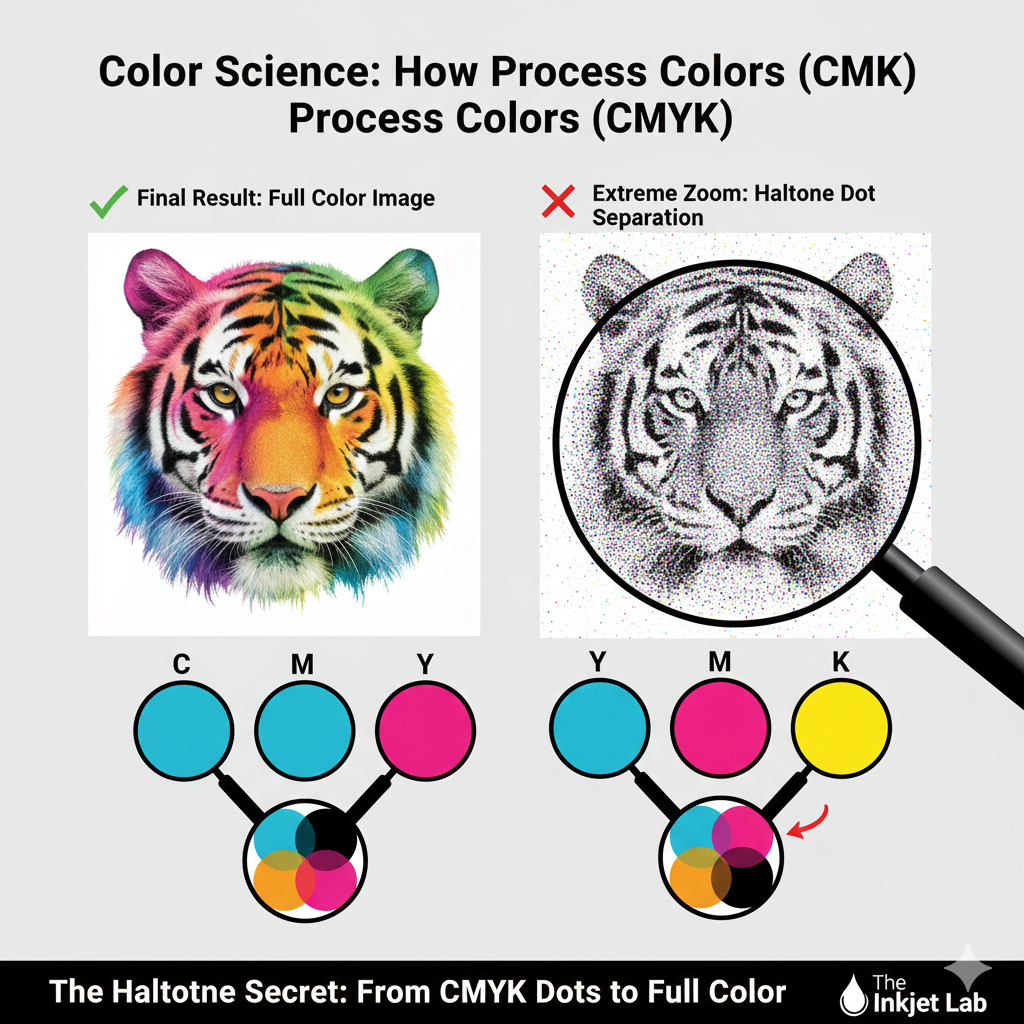

Process Colors refers to the subtractive color model used in the majority of the world’s commercial and home printing systems. This method creates a vast spectrum of colors by overlapping small dots of four primary inks: Cyan (C), Magenta (M), Yellow (Y), and Black (K). The letter “K” stands for “Key,” referring to the “Key Plate” used in traditional printing to add detail and contrast to an image.

Read more

Why It Matters: Impact and Use

Understanding the mechanics of process colors is vital for anyone in digital decoration, as it dictates how a design moves from a digital screen to a physical product. Expertise in color theory is ensuring that brand colors are reproduced accurately across different media.

- Technical Accuracy in DTF & Sublimation: In processes like Direct To Film (DTF) or Sublimation, the RIP software must precisely calculate the “ink limit” of these four colors to prevent bleeding while still achieving a vibrant result.

- Halftoning & Dithering: Printers do not actually mix inks to create new colors inside the tank. Instead, they print tiny dots of the four process colors in varying sizes and densities. The human eye then perceives these overlapping dots as a single, solid color. This is why a print looks different under a magnifying glass than it does from a distance.

- RGB vs. CMYK Gamut: Computers screens use the RGB (Red, Green, Blue) additive model, which has a wider “gamut” (range of colors) than CMYK. This is why some “neon” or “fluorescent” colors seen on a monitor may look “dull” when printed using standard process colors. Managing this transition is key to maintaining a high CTR (Click-Through Rate) for e-commerce product photos.

All clamshell Heat Presses

Comparison: RGB vs. CMYK (Process Colors)

| Feature | RGB (Red, Green, Blue) | CMYK (Process Colors) |

| Media Type | Digital Screens (Light). | Physical Media (Ink/Toner). |

| Color Method | Additive (Adds to black). | Subtractive (Subtracts from white). |

| Gamut Range | Wide (Includes neon/brights). | Limited (Standard print range). |

| Primary Use | Web Design, Social Media. | Apparel, Signage, Brochures. |

Frequently Asked Questions

Why is Black called ‘K’ in CMYK?

The ‘K’ stands for ‘Key.’ In traditional offset printing, the black plate was the ‘Key Plate’ that provided the essential detail and alignment for the other three colors (Cyan, Magenta, and Yellow).

Why do my printed colors look less bright than my screen?

This is due to the difference in color gamuts. Screens use light (RGB) to create color, allowing for brighter neons. Printers use physical ink (CMYK), which absorbs light, resulting in a slightly smaller range of reproducible colors.

Can process colors create every possible color?

While CMYK can create thousands of colors, it cannot perfectly reproduce specific ‘Spot Colors’ (like Pantone) or metallic/neon shades. For those, specialized fifth-color inks or metallic foils are required.