In the garment decoration and heat transfer industry, Recovery Time is the duration required for a heat press’s heating element (the upper platen) to return to its programmed operating temperature after a pressing cycle is completed. When the hot platen contacts a room-temperature substrate—such as a t-shirt, hoodie, or ceramic tile—the substrate acts as a “heat sink,” absorbing thermal energy and causing the platen’s temperature to drop momentarily.

Read more

Why It Matters: Impact and Use

Recovery time is a critical performance metric that directly influences both production speed and product durability. Understanding this technical aspect is vital for establishing E-E-A-T (Expertise, Authoritativeness, and Trustworthiness) in professional printing environments.

- Quality Control: Professional-grade presses use advanced PID (Proportional-Integral-Derivative) controllers to minimize the recovery gap, ensuring the temperature stays within a very narrow range (Index: Thermal Stability).

- Consistency and Adhesion: Most transfer materials (DTF, Sublimation, or HTV) have a specific “melt window.” If an operator begins the next press before the machine has recovered (e.g., pressing at 145°C when the recipe calls for 160°C), the adhesive may not fully bond. This leads to poor wash-fastness and customer complaints.

- Throughput & ROI: In high-volume “Print-on-Demand” shops, every second counts. A high-quality press with a fast recovery time allows for continuous workflow. A press that takes 45 seconds to recover between shirts significantly lowers your daily output and overall ROI (Return on Investment).

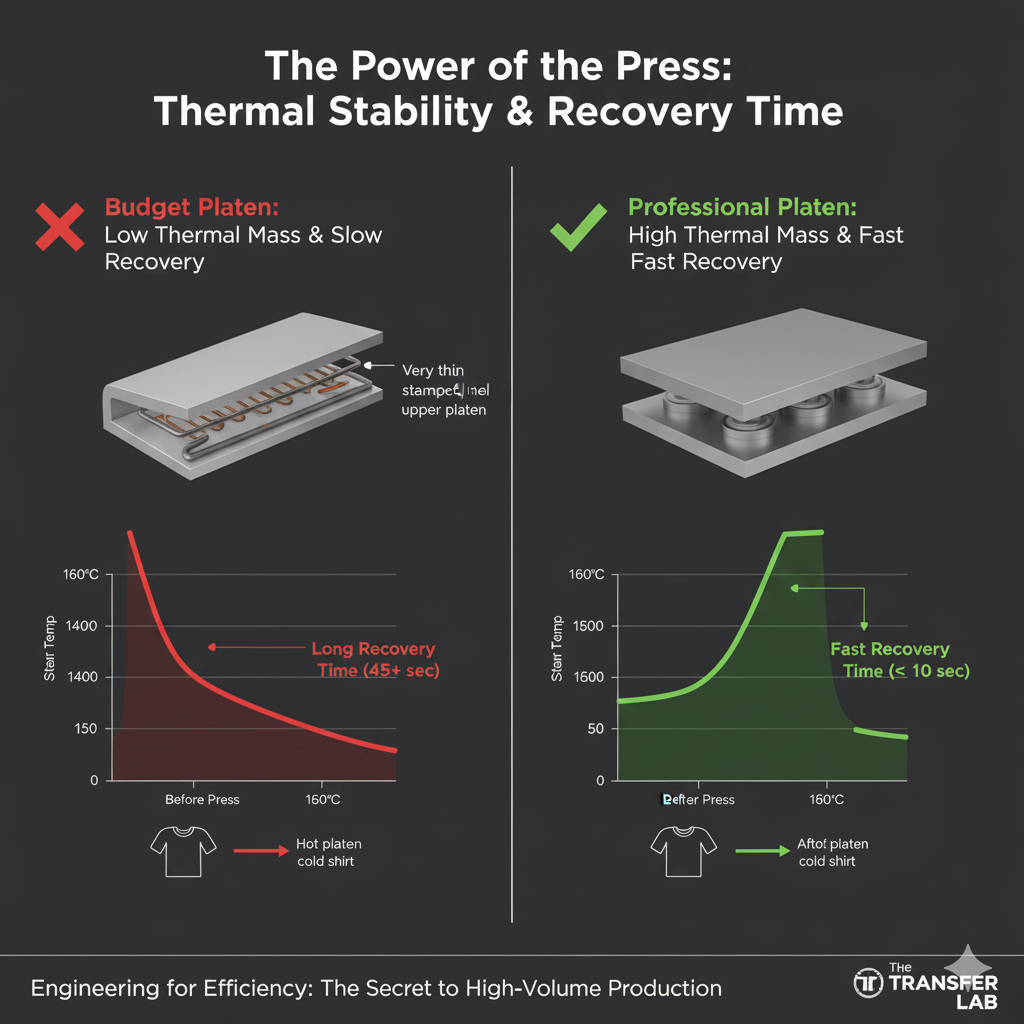

- Thermal Mass vs. Wattage: Recovery speed is determined by two main factors:

- Wattage: Higher wattage heating elements can pump energy back into the platen faster.

- Platen Thickness: Thicker aluminum platens have higher “thermal mass,” meaning they hold heat better and drop in temperature less severely than thinner, cheaper plates.

- Quality Control: Professional-grade presses use advanced PID (Proportional-Integral-Derivative) controllers to minimize the recovery gap, ensuring the temperature stays within a very narrow range (Index: Thermal Stability).

All clamshell Heat Presses

Comparison: Hobbyist vs. Professional Recovery

| Feature | Budget / Hobbyist Press | Professional Press (e.g., TheMagicTouch) |

| Typical Drop | 10°C – 20°C per cycle | 2°C – 5°C per cycle |

| Recovery Speed | 30 – 60 Seconds | 5 – 15 Seconds |

| Platen Material | Thin / Stamped Steel | Thick Cast Aluminum |

| Workflow | Intermittent (Slow) | Continuous (High Volume) |

Frequently Asked Questions

Why does my heat press temperature drop during a press?

This is a natural thermodynamic reaction. The cold garment absorbs heat from the platen. The amount of drop depends on the thickness of the platen and the energy efficiency of the heating element.

Can I start the next press before the recovery time is finished?

It is not recommended. If the temperature is below the manufacturer’s specification for the transfer media, the adhesive may not activate correctly, resulting in the design peeling off after washing.

How can I improve the recovery time of my heat press?

While you cannot change the wattage, you can help the press by ‘pre-heating’ your lower platen and garments. This ensures the machine isn’t losing extra heat to a cold base or damp fabric.