In the garment decoration industry, Stretch refers to the elasticity and recovery properties of a Heat Transfer Vinyl (HTV) or “Flexfolie.” It is the ability of the transfer material to expand in tandem with the textile fibers when pulled and, crucially, to return to its original shape without cracking, peeling, or deforming.

Read more

Why It Matters: Impact and Use

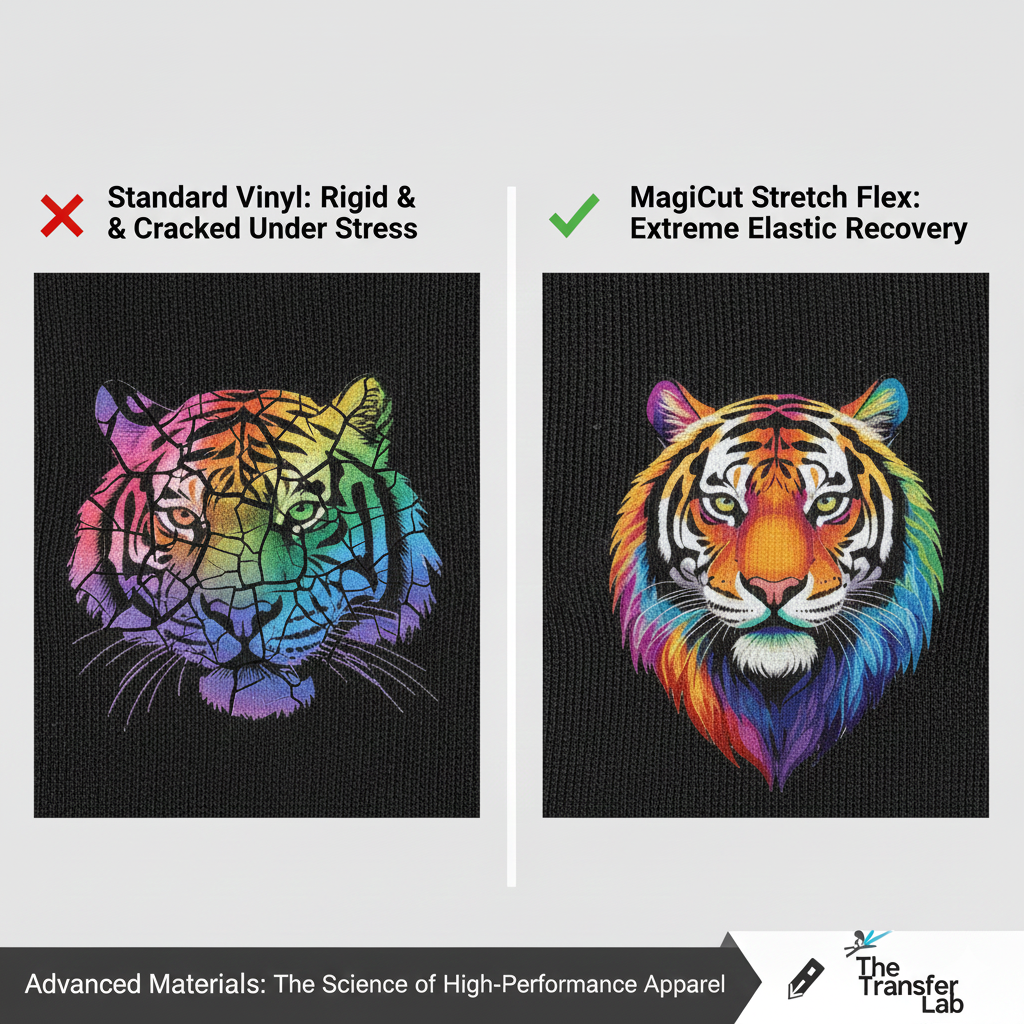

For professional decorators, choosing a material with high stretchability is essential for ensuring the longevity and “hand-feel” of custom apparel. Utilizing the correct technical media is a core component of E-E-A-T (Expertise, Authoritativeness, and Trustworthiness), preventing the common “cracked logo” syndrome found in low-quality sportswear.

- Optimizing ROI: While specialized stretch vinyl may have a higher price point per meter, it significantly increases your ROI (Return on Investment) by reducing returns and warranty claims from customers whose logos cracked after the first use.

- Performance on High-Lycra Fabrics: Modern performance wear—such as leggings, cycling jerseys, and swimwear—contains high percentages of Elastane or Lycra. Standard vinyl is too rigid for these textiles; as the athlete moves, the fabric stretches, but the vinyl resists, leading to Delamination (the bond breaking).

- Durability and Recovery: A true “Stretch” flex (like MagiCut Stretch) is engineered with a thinner, more pliable polyurethane (PU) base. This allows the design to mirror the movement of the wearer, ensuring that the print remains intact even after hundreds of stretch-and-recovery cycles.

- Soft “Hand” (Texture): Stretch films are typically thinner than standard flex. This results in a much softer feel on the garment, which is particularly important for children’s clothing and base layers where skin irritation must be avoided.

All clamshell Heat Presses

Comparison: Standard Flex vs. Stretch Flex

| Feature | Standard Flexfolie | MagiCut Stretch Flex |

| Ideal Fabric | 100% Cotton, Poly/Cotton | Lycra, Spandex, Performance Poly |

| Material Thickness | 90–100 Microns | 50–60 Microns (Ultra-thin) |

| Elasticity | Low (Will crack if over-pulled) | High (Extreme elastic recovery) |

| Application | T-shirts, Hoodies, Tote bags | Leggings, Swimwear, Compression gear |

Frequently Asked Questions

Why does my vinyl crack when the shirt is stretched?

Cracking occurs when the elasticity of the vinyl is lower than the elasticity of the fabric. If you are printing on rib-knit or spandex-blend shirts, you must use a specialized Stretch Flexfolie that can expand with the fibers.

Can I use MagiCut Stretch on regular cotton T-shirts?

Yes! While it is designed for high-stretch fabrics, MagiCut Stretch works excellently on cotton. Many professionals prefer it for all garments because its thin profile provides a premium, screen-printed feel.

How do I wash garments with stretch transfers?

To maintain the elasticity, it is recommended to wash the garment inside out at a maximum of 40°C-60°C. Avoid using fabric softeners, as they can break down the elastic bonds in both the fabric and the adhesive.