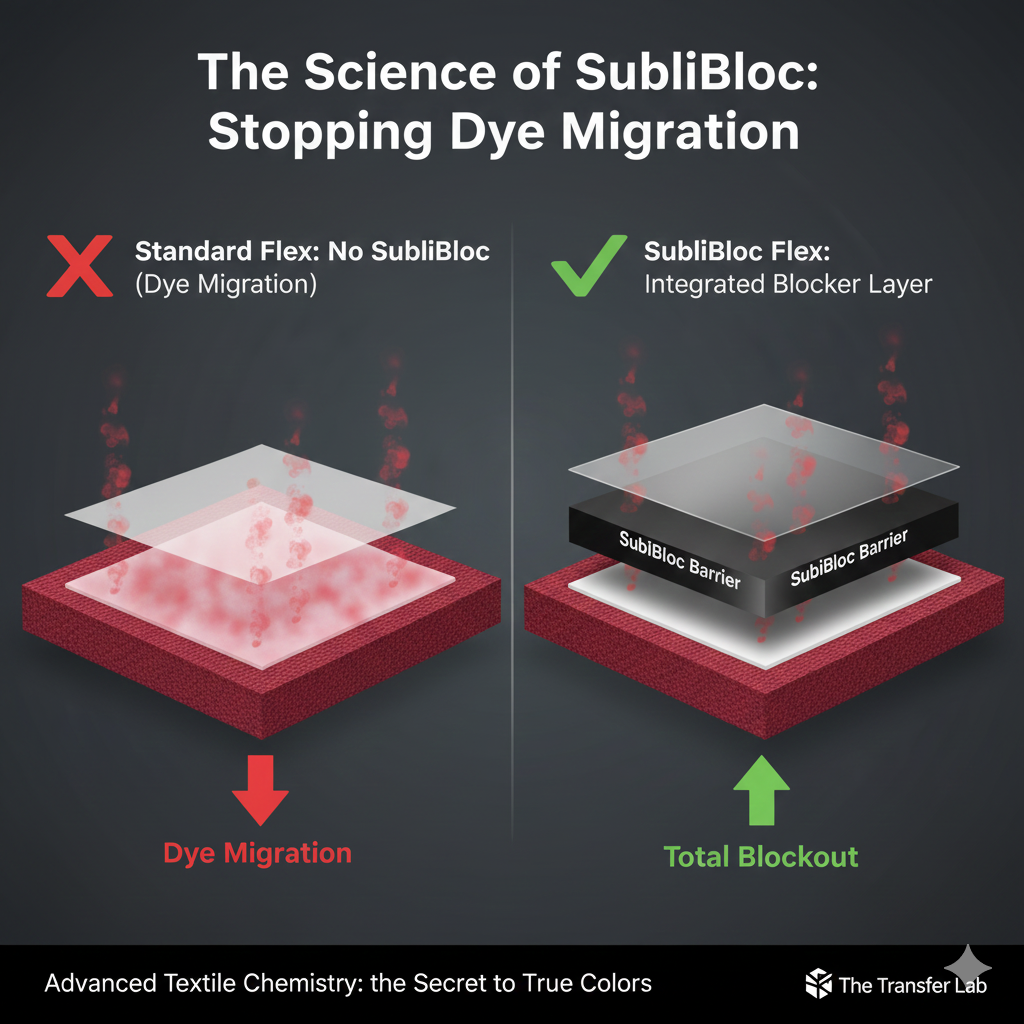

SubliBloc (also known as Subli-Stop or BlockOut) is a specialized technical barrier integrated into professional-grade Heat Transfer Vinyl (Flexfolie) or printable media. Its primary function is to serve as an impenetrable “shield” that prevents the migrated dyes of polyester fabrics from “bleeding” into the applied transfer during and after the heat press process.

Read more

Why It Matters: Impact and Use

In the high-performance sportswear and teamwear industry, Dye Migration is a common technical failure that undermines E-E-A-T (Expertise, Authoritativeness, and Trustworthiness). Without a SubliBloc layer, a vibrant white logo applied to a red polyester jersey will slowly turn pink over time as the fabric dyes “gas out” into the vinyl.

- Optimizing ROI: While SubliBloc media may have a slightly higher upfront cost, it eliminates the need for expensive “re-dos” and customer returns caused by faded or discolored logos, significantly improving your long-term ROI (Return on Investment).

- Preventing “Bleeding”: Polyester is colored via sublimation, where dyes are bonded to fibers using intense heat. When you reheat that garment to apply a transfer, those dyes can reactivate. SubliBloc contains a charcoal or aluminum-based layer that physically traps these gaseous dyes, maintaining the original color of your print.

- Low-Temperature Application: Most SubliBloc films are engineered to activate at lower temperatures (e.g., 130°C – 140°C). By reducing the heat required for the transfer, the polyester dyes in the garment are less likely to reactivate, providing a secondary layer of protection against discoloration.

- Essential for High-Contrast Designs: The risk of bleeding is highest when applying light-colored transfers (White, Yellow, Neon) onto dark polyester garments (Navy, Red, Black). SubliBloc ensures that a “White” print stays “White” for the entire lifespan of the garment.

All clamshell Heat Presses

Comparison: Standard Flex vs. SubliBloc Flex

| Feature | Standard Flexfolie | SubliBloc / Subli-Stop |

| Barrier Layer | None | Integrated Charcoal/Blocker Layer |

| Application Temp | Standard (150°C – 160°C) | Low Temp (130°C – 140°C) |

| Primary Use | Cotton and Poly/Cotton blends | Sublimated Polyester / Teamwear |

| Bleed Resistance | Low (Susceptible to migration) | Maximum (Total Blockout) |

Frequently Asked Questions

Why did my white vinyl turn the color of the T-shirt

This is called ‘Dye Migration.’ The dyes in polyester fabric turn into gas when heated and ‘bleed’ into the vinyl. To prevent this, you must use a SubliBloc or Subli-Stop vinyl which contains a special barrier layer to trap the dyes.

Does SubliBloc make the transfer feel thicker?

Because it contains an extra technical layer, SubliBloc vinyl is often slightly thicker than standard flex. However, modern premium versions are engineered to remain flexible and soft to the touch while maintaining total opacity.

Can I use SubliBloc on softshell jackets?

Yes. Softshell jackets are notorious for extreme dye migration. Using a SubliBloc Flex is highly recommended for softshells to ensure your logos do not suffer from discoloration over time.