A Swing-Away heat press is a professional-grade machine where the upper heating platen pivots horizontally 90 to 180 degrees away from the lower platen. Unlike a “Clamshell” press that opens like a book, the swing-away design moves the heat source completely out of the operator’s workspace, providing a clear, top-down view and unobstructed access to the printing surface.

Read more

Why It Matters: Impact and Use

Swing-Away (Heat Press Design)

Definition: A Swing-Away heat press is a professional-grade machine where the upper heating platen pivots horizontally 90 to 180 degrees away from the lower platen. Unlike a “Clamshell” press that opens like a book, the swing-away design moves the heat source completely out of the operator’s workspace, providing a clear, top-down view and unobstructed access to the printing surface.

Why It Matters: Impact and Use

For professional decorators and high-output businesses, the swing-away design is often the preferred choice for safety, precision, and versatility. Investing in this architecture enables the handling of a wider variety of substrates that standard presses cannot manage.

- High-Pressure Capabilities: The robust central-pivot construction of swing-away models allows for significantly higher pressure values. This is a technical necessity for specific transfer papers, such as TheMagicTouch WoW Dark, which require intense pressure to “marry” the transfer layers successfully.

- Enhanced Safety & Ergonomics: By moving the 160°C+ heating element away from the workspace, the risk of accidental burns to the operator’s hands and arms is significantly reduced. This creates a more comfortable, “heat-free” environment for meticulous layout work.

- Precision Placement: Because the upper platen is moved to the side, the operator has a perfect 90-degree view of the garment. This is crucial for Schema (alignment) of complex multi-layered transfers or small chest logos where accuracy is vital for a high-quality finished product.

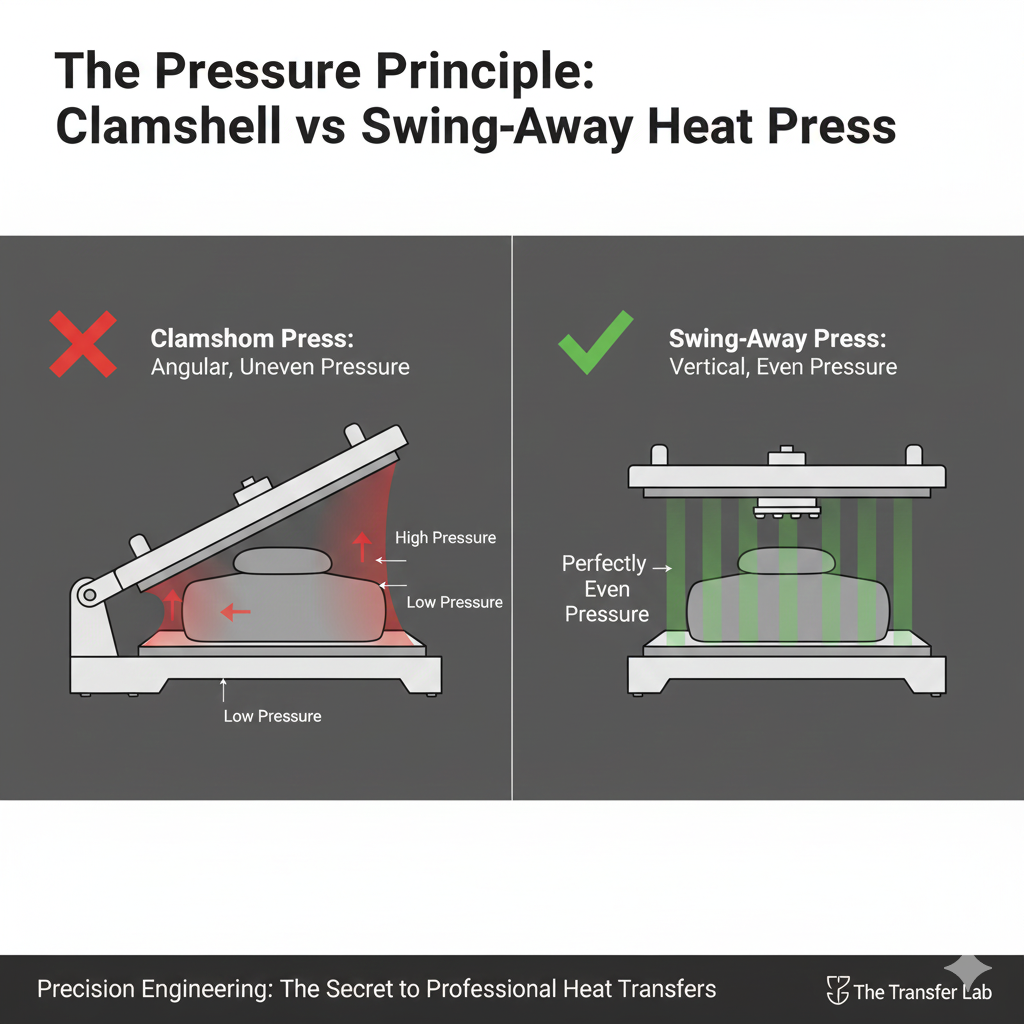

- Linear Pressure Distribution: Swing-away presses typically apply pressure vertically (straight down) rather than at an angle. This ensures perfectly even pressure across the entire surface—an essential requirement for thick items like ceramic tiles, plaques, or heavy hoodies where a clamshell might “pinch” the back edge.

All clamshell Heat Presses

Comparison: Swing-Away vs. Clamshell

| Feature | Swing-Away Heat Press | Clamshell Heat Press |

| Space Required | High (Needs side clearance) | Low (Compact footprint) |

| Pressure Direction | Vertical (Even/Linear) | Angular (Scissor-like) |

| Safety | High (Heat moved away) | Moderate (Heat remains above hands) |

| Substrate Thickness | Versatile (Tiles, Woods, Garments) | Mostly Garments & Thin items |

| Layout Visibility | 100% Unobstructed | Partially Obstructed |

Frequently Asked Questions

Is a swing-away heat press better than a clamshell?

It depends on your needs. Swing-away presses offer better safety and more even pressure for thick items, while clamshell presses are faster for high-volume t-shirt production and take up less bench space.

Does a swing-away press require more space?

Yes. Because the top platen swings to the side, you need clear workspace to the left or right of the machine. It is not ideal for cramped ‘corner’ setups.

Why is vertical pressure important?

Vertical pressure ensures that the heat and weight are applied equally to the front and back of the substrate. This prevents ‘ghosting’ in sublimation and ensures that laser transfers bond correctly to the entire surface.