Teflon is the registered brand name for Polytetrafluoroethylene (PTFE), a synthetic fluoropolymer of tetrafluoroethylene. Known for being one of the most slippery substances in existence, its molecular structure provides exceptional heat resistance (up to 260°C), high chemical stability, and a very low coefficient of friction. In the printing industry, it is primarily used as a non-stick coating for heat press platens or as a protective reusable sheet.

Read more

Why It Matters: Impact and Use

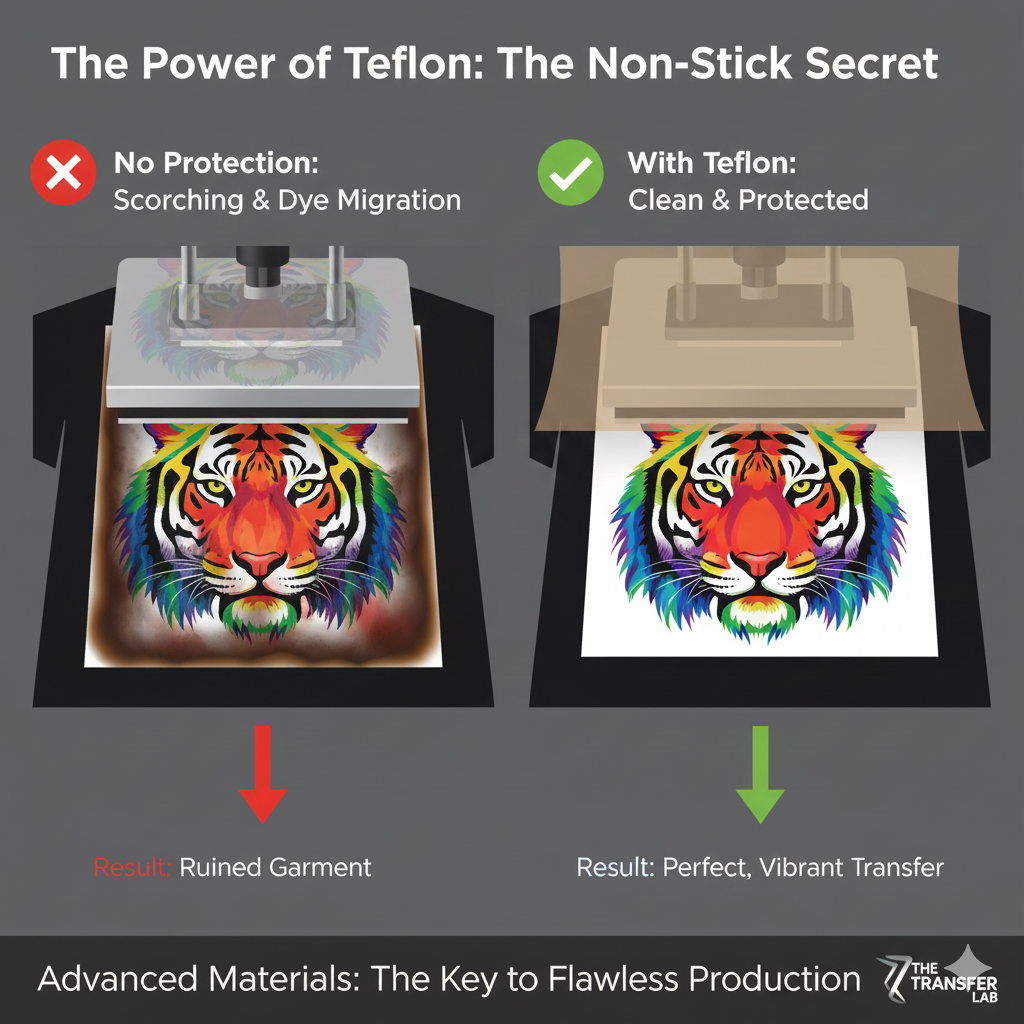

In heat transfer and sublimation printing, Teflon is a critical safeguard for both the equipment and the garment. Utilizing Teflon effectively is a hallmark of professional E-E-A-T (Expertise, Authoritativeness, and Trustworthiness), as it prevents common production failures like “ghosting” or “ink migration.”

- Friction Reduction: The low coefficient of friction allows the heat press to glide open and closed without pulling or shifting the transfer media, which is vital for maintaining sharp registration and high-quality output.

- Non-Stick Platen Protection: Most professional heat press plates are factory-coated with Teflon. This ensures that if a transfer is placed upside down or adhesive escapes the edges, it will not permanently bond to the metal heating element.

- Preventing Contamination: During the Sublimation process, dyes turn into a gas. Without a Teflon sheet or coating, these gases can settle on the upper platen and “re-sublimate” onto the next garment, causing unwanted stains or “ghosting.” A Teflon surface can be easily wiped clean, protecting your ROI (Return on Investment) by reducing spoiled stock.

All clamshell Heat Presses

Comparison: Teflon-Coated Platen vs. Separate Teflon Sheet

| Feature | Teflon-Coated Platen | Separate Teflon Sheet |

| Primary Function | Permanent non-stick surface. | Removable protective barrier. |

| Maintenance | Requires careful cleaning to avoid scratches. | Easily replaceable if damaged or stained. |

| Heat Impact | Direct heat transfer. | Minor heat buffer (helps prevent scorching). |

| Versatility | Fixed to the machine. | Can be used as a “wrap” or loose sheet. |

Frequently Asked Questions

Do I need to use a Teflon sheet if my press is already Teflon-coated?

While not always strictly necessary, using an additional Teflon sheet provides an extra layer of protection. It is easier to clean or replace a sheet than it is to repair a scratched coating on the expensive heating platen.

How do I clean ink or adhesive off my Teflon surface?

You should wipe the Teflon surface while it is still warm using a soft, non-abrasive cloth. For stubborn residue, a small amount of specialized citrus-based cleaner can be used, but avoid metal scrapers which will ruin the non-stick properties.

Can a Teflon sheet cause my transfers to fail?

Teflon is a slight insulator. If you use an exceptionally thick sheet, you may need to increase your pressing time by 5-10 seconds or increase the temperature by 5°C to compensate for the thermal barrier.