Textile Film, widely known as Flex Film or Heat Transfer Vinyl (HTV), is a specialized decorative medium consisting of a pigmented polyurethane (PU) or polyvinyl chloride (PVC) layer mounted on a clear, heat-resistant carrier sheet. It is designed to be cut into custom shapes, logos, or lettering using a digital cutting plotter and then fused onto fabric using heat and pressure.

Read more

Why It Matters: Impact and Use

In the custom apparel and sportswear industries, Textile Film is the primary method for adding names, numbers, and single-color logos to garments. Mastering the technical application of these films is a core component of E-E-A-T (Expertise, Authoritativeness, and Trustworthiness), ensuring that decorated products withstand the rigors of athletic use and frequent laundering.

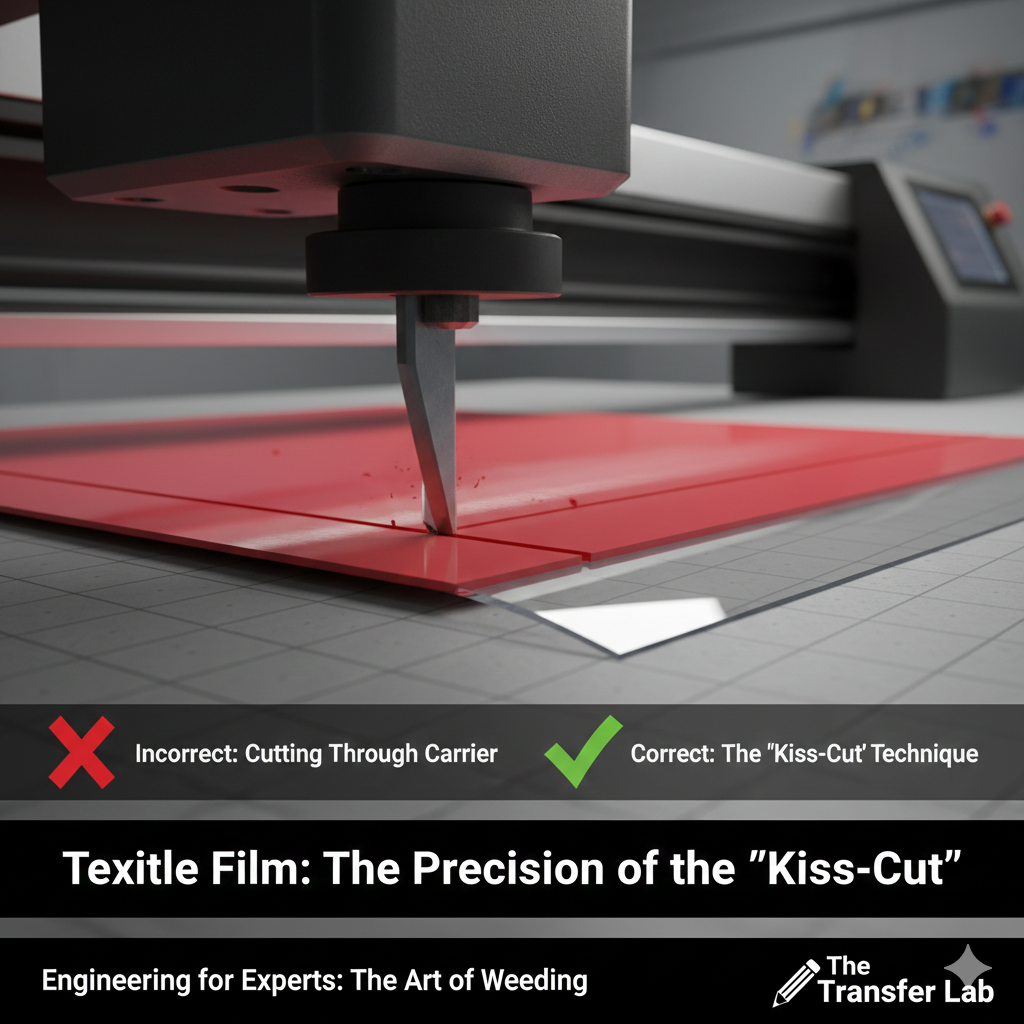

- Precision Plotting & Weeding: The construction of the film allows a cutting plotter to perform a “kiss-cut”—cutting through the color layer while leaving the carrier intact. The process of removing the unwanted excess material is known as “Weeding.”

- Durability and “Hand-Feel”: Modern textile films are engineered to be incredibly thin (often 50–90 microns). This provides a soft “hand-feel” that moves with the garment, preventing the rigid, plastic-like sensation found in lower-quality alternatives.

- Specialized Applications: Textile films are available in various technical formulations to solve specific challenges:

- Stretch Flex: High elasticity for Lycra and Spandex.

- Subli-Block: Prevents dye migration on sublimated polyester.

- High-Tack: Features a sticky carrier for intricate, detailed designs that are difficult to weed.

- Production ROI: Because it requires no ink or drying time, Textile Film is the most cost-effective and efficient way to handle “runs of one” (personalization), significantly increasing a shop’s ROI (Return on Investment) for teamwear and uniforms.

All clamshell Heat Presses

Comparison: Textile Film vs. Screen Printing

| Feature | Textile Film (Flex/HTV) | Screen Printing |

| Setup Time | Minimal (Cut & Press) | Extensive (Screens & Emulsion) |

| Ideal Run Size | 1 – 20 pieces | 50+ pieces |

| Personalization | Easy (Names/Numbers) | Difficult / Expensive |

| Color Depth | Solid, vibrant colors | Possible gradients / halftones |

Frequently Asked Questions

What is the difference between Flex Film and HTV?

There is no functional difference. ‘Flex Film’ or ‘Textile Film’ are the terms commonly used in Europe, while ‘Heat Transfer Vinyl (HTV)’ is the standard terminology used in the United States.

Why is my textile film peeling off after washing?

Peeling is usually caused by insufficient pressure or heat during the application process, or ‘cold peeling’ a film that was designed for ‘hot peel.’ Always check the specific technical data sheet for the film’s required settings.

Do I need to mirror my design before cutting textile film?

Yes. Because you are cutting through the back of the color layer (the side with the adhesive), you must mirror or flip your design horizontally so that it appears correctly when turned over and pressed onto the garment.