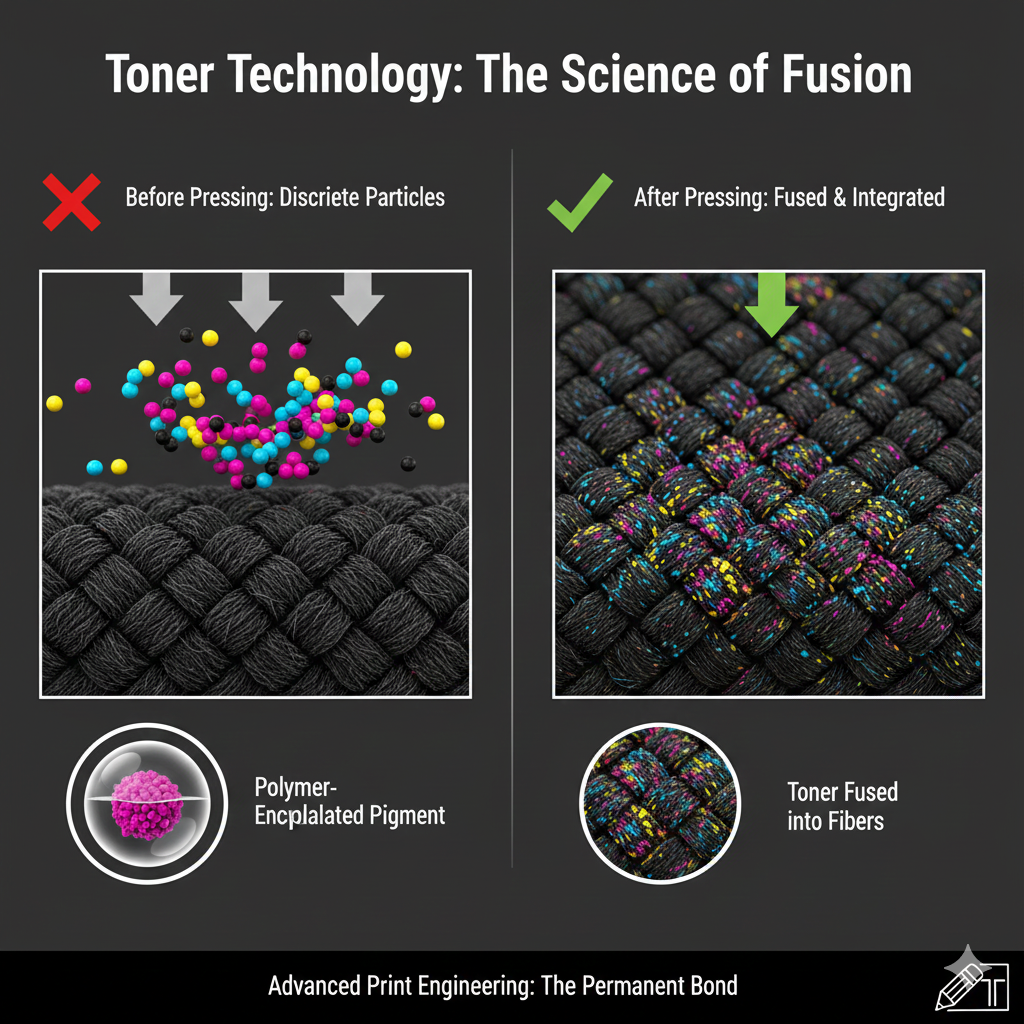

Toner is the dry, powdery printing medium used in electrostatic printing systems, such as Laser and LED printers. Unlike liquid ink, toner is composed of microscopic pigment particles encapsulated in a polymer resin (plastic). These particles are engineered to hold a specific electrostatic charge, allowing them to be precisely manipulated by a laser beam or LED array and eventually fused to a substrate using intense heat and pressure.

Read more

Why It Matters: Impact and Use

In the world of professional heat transfers, toner is the “engine” of the design. Understanding its chemical and physical properties is vital for establishing E-E-A-T (Expertise, Authoritativeness, and Trustworthiness), as the quality of the toner directly impacts the durability and color fidelity of the final decorated product.

- Electrostatic Precision: Printers use a drum or belt to create a “latent image” via static electricity. The toner particles jump from the developer unit to the charged areas of the drum with extreme precision. This allows for high-resolution graphics and sharp text that liquid inkjet systems often struggle to replicate on transfer media.

- The Fusing Process (Fixation): Because toner is plastic-based, it must be “fused” to the paper. Inside the printer, heated rollers melt the polymer resin, bonding the pigment to the transfer sheet. This is a critical step; if the toner is not properly fused, it will flake off during the heat press cycle.

- White Toner Technology: One of the most significant advancements in the industry is the development of White Toner. This allows decorators to print a solid white base or white highlights, enabling full-color transfers onto dark textiles and hard surfaces that were previously impossible with standard CMYK printers.

- Durability and Wash-Fastness: Toner-based transfers are known for their high resistance to UV fading and chemical degradation. When correctly applied with a heat press, the plastic polymer of the toner “remelts” and weaves into the fibers of the garment, creating a bond that can last for dozens of wash cycles.

- ROI and Maintenance: Toner does not “dry out” like liquid ink, making it much more reliable for businesses that do not print every day. This reliability reduces maintenance costs and head-cleaning waste, leading to a better ROI (Return on Investment).

All clamshell Heat Presses

Comparison: Toner vs. Inkjet Ink

| Feature | Laser/LED Toner | Inkjet Ink |

| Composition | Dry Polymer / Plastic Powder | Liquid Pigment or Dye |

| Application Method | Static Electricity & Heat | Piezo or Thermal Spray |

| Clogging Risk | Extremely Low | High (if not used regularly) |

| Media Compatibility | Wide (Papers, Films, Hard Surfaces) | Mostly Absorbent Media |

| Best For | High-Speed, Professional Transfers | Photographic Photos / Hobbyist |

Frequently Asked Questions

Can I use standard office toner for heat transfers?

Yes, standard laser/LED toner can be used for many transfers. However, professional-grade toners (like those in OKI or Ricoh printers) are specifically formulated to have a higher pigment density and better melting points for superior results on textiles.

Why is my toner flaking off the transfer paper?

This is usually a ‘fusing’ issue. If the printer’s media settings are set to ‘Plain Paper’ instead of ‘Heavy’ or ‘Label’ mode, the fuser does not get hot enough to melt the toner onto the thick transfer sheet.

Does white toner work the same way as colored toner?

Yes. It follows the same electrostatic process. The only difference is the pigment inside. White toner is essential for creating an underbase so that CMYK colors appear vibrant on dark-colored garments.