Toner Transfer is a specialized category of digital transfer media designed exclusively for color Laser and LED printers. Unlike standard “film-based” transfers that apply a plastic coating or “window” over the entire surface, a true toner transfer—such as TheMagicTouch CPM 6.2—utilizes the chemical properties of the toner itself as the bonding agent. The process transfers only the printed toner particles to the substrate, resulting in a clean, professional finish with no visible residue on the unprinted areas.

Read more

Why It Matters: Impact and Use

Toner transfer technology is a game-changer for “hard surface” decoration. It allows businesses to offer a massive range of personalized products without the high setup costs of screen printing or the material limitations of sublimation.

- “No-Background” Finish: Because only the toner moves from the paper to the product, there is no “clear box” or polymer film surrounding the design. This makes it ideal for high-end items like awards, leather notebooks, and wooden crates where the original texture of the material should remain visible.

- Extreme Versatility: Toner transfers can decorate materials that are traditionally difficult to print on, provided they can withstand the heat and pressure of a press.

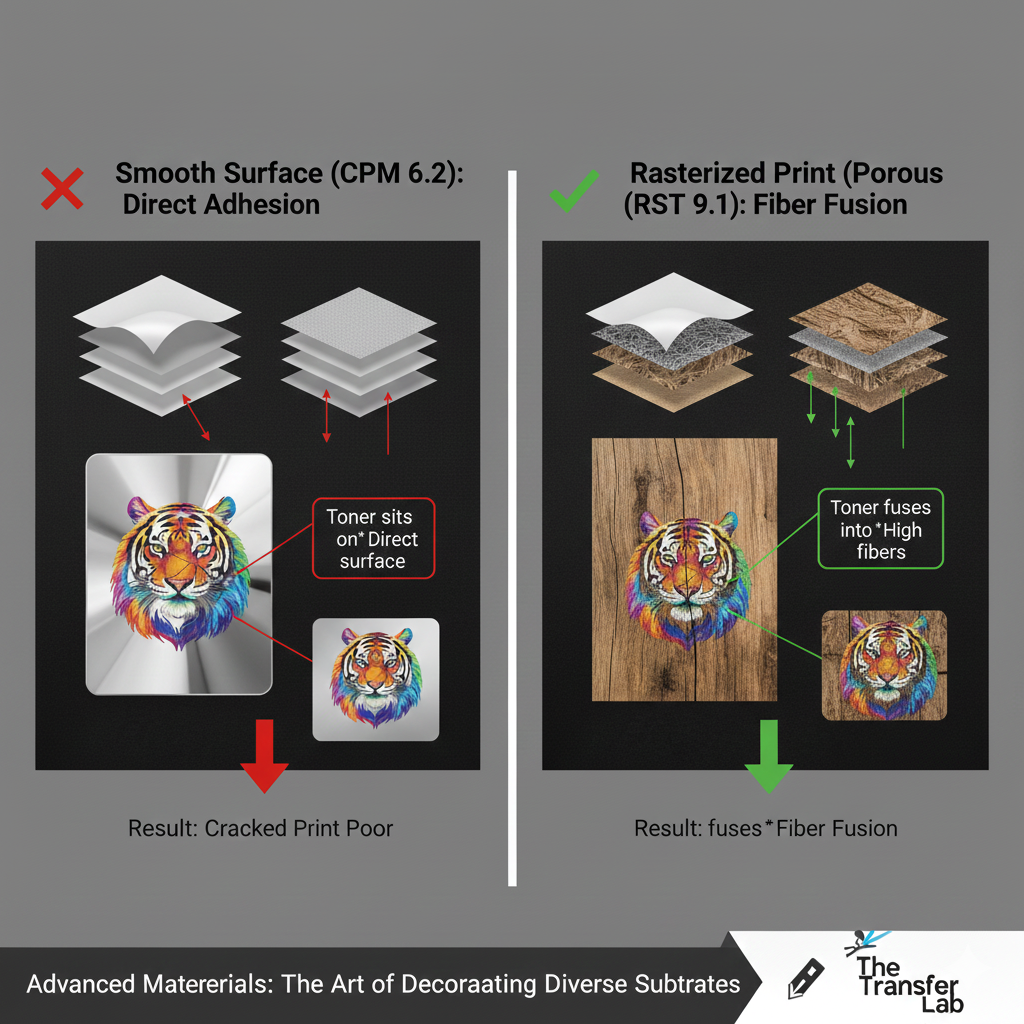

- TheMagicTouch CPM 6.2: The “Global Player” for smooth surfaces including metal, glass, acrylic, PU leather, and magnetic foil.

- TheMagicTouch RST 9.1: Specifically engineered for porous or rough surfaces like untreated wood, cork, and stone.

- Technical Precision & Tools: Achieving a perfect transfer on hard goods often requires managing thermal shock and surface irregularities. The use of specialized Application Tools, such as the TheMagicTouch Application Sponge, helps distribute pressure evenly and protects delicate surfaces like acrylic from cracking under the heat press.

- Production ROI: This method offers a significantly higher ROI (Return on Investment) for short-run promotional items. You can produce a single custom-printed ceramic tile or a leather menu cover in under two minutes with virtually zero cleanup.

All clamshell Heat Presses

Comparison: Toner Transfer vs. Standard Film Transfer

| Feature | Toner Transfer (TheMagicTouch CPM 6.2 / TheMagicTouch RST 9.1) | Standard Film Transfer (TheMagicTouch TTC 3.1 / TheMagicTouch WOW Dark) |

| Transfer Layer | Toner Only (No Film) | Toner + Polymer Coating |

| Primary Use | Hard Surfaces (Wood, Metal, Glass) | Textiles (T-shirts, Bags, Caps) |

| Background | None (Self-Weeding effect) | Possible “window” if not trimmed |

| Texture | Mimics the substrate | Slightly raised or plastic feel |

Frequently Asked Questions

What is the difference between TheMagicTouch CPM 6.2 and TheMagicTouch RST 9.1?

TheMagicTouch CPM 6.2 is designed for smooth, non-porous hard surfaces like metal, glass, and acrylic. heMagicTouch RST 9.1 is specifically developed for porous or rougher surfaces like wood and cork, where the toner needs to settle deeper into the texture for a permanent bond.

Do I need a special printer for toner transfers?

You need a high-quality dry-toner Laser or LED printer. While standard CMYK printers work for light surfaces, using a White Toner printer (like OKI) with TheMagicTouch CPM 6.2 allows you to print vibrant colors onto dark or colored hard surfaces.

How durable are toner transfers on hard surfaces?

Once fused by the heat press, the toner becomes part of the surface. On items like metal or wood, it is extremely durable. For glass or ceramics, these are generally intended for decorative use and are not recommended for heavy dishwasher cycles.