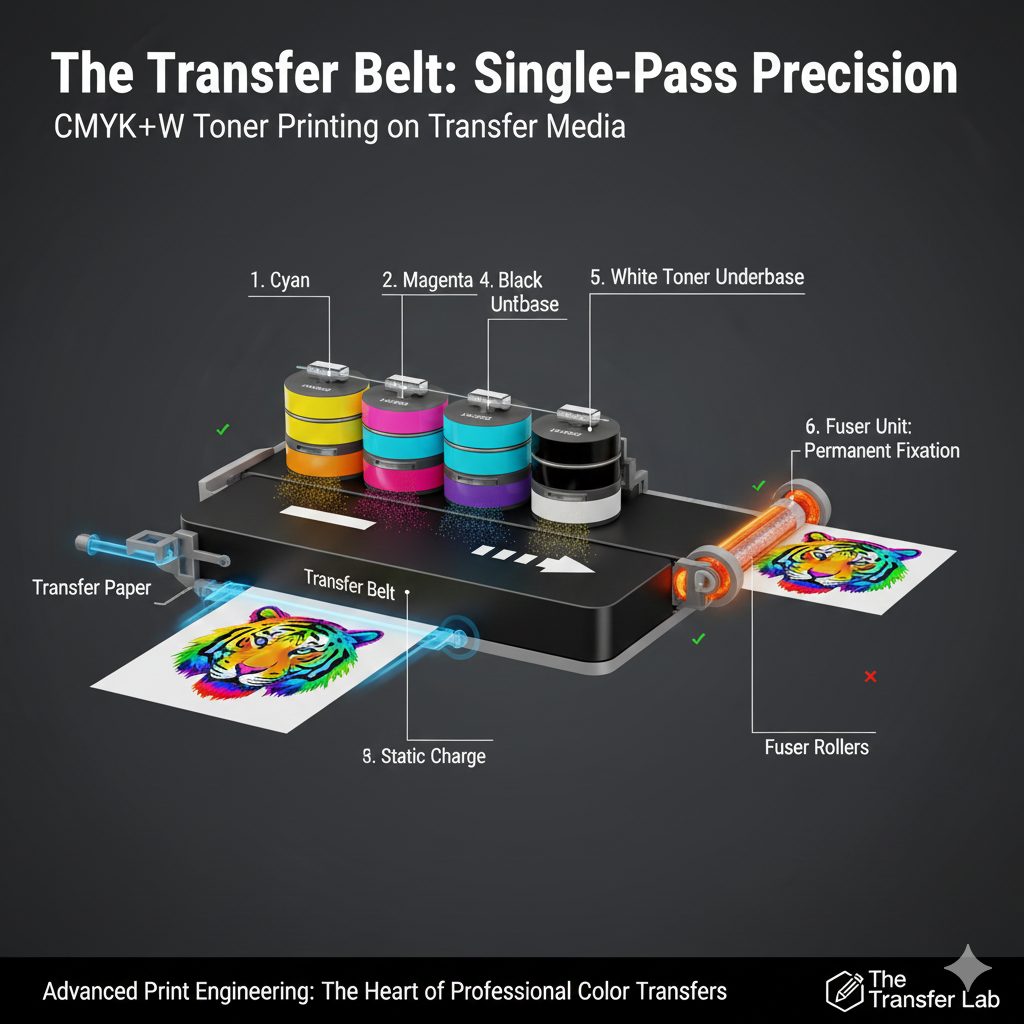

The Transfer Belt (also known as an Intermediate Transfer Belt or ITB) is a critical internal component of a color Laser or LED printer. It is a large, rotating conveyor-style belt that serves two primary roles: precisely transporting the media (transfer paper) through the internal engine and facilitating the electrostatic transfer of toner from the image drums onto that media to form the final print.

Read more

Why It Matters: Impact and Use

In the heat transfer industry, the transfer belt is the “heart” of the printing process. Its design directly determines the printer’s ability to handle the heavy, coated papers required for professional garment decoration.

- Static Precision & Toner Placement: The belt uses a controlled electrostatic charge to “pull” toner particles from the four (or five) separate color drums (CMYK + White) onto the paper. In OKI LED printers, this happens in a single pass, which is why they are renowned for perfect registration (alignment) on thick transfer sheets.

- Media Versatility (The “Straight-Through” Path): High-quality transfer belts are designed to handle “heavy” media settings. Because the belt is flat and flexible, it allows the paper to travel in a straight path rather than curling around tight rollers. This is essential for thick products like TheMagicTouch WOW Dark or TheMagicTouch CPM 6.2, which would jam in a standard office printer.

- Preventing Image Ghosting: A clean, well-maintained transfer belt ensures that no residual toner from the previous print remains to contaminate the next. Most professional belts include a “cleaning blade” to ensure every print is as crisp as the first.

- ROI and Component Lifespan: The transfer belt is a “consumable” item with a specific page life (e.g., 30,000 to 60,000 pages). Monitoring the health of the belt prevents streaks and “mottled” colors, ensuring a high ROI (Return on Investment) by minimizing wasted transfer paper, which is significantly more expensive than standard copy paper.

All clamshell Heat Presses

Comparison: Transfer Belt vs. Traditional Rollers

| Feature | Transfer Belt System (e.g., OKI/Ricoh) | Traditional Roller System |

| Paper Path | Straight-through (Best for thick media) | Curved/U-turn (Risk of jams) |

| Color Registration | High Precision (Single pass) | Variable (Multiple passes) |

| Media Weight | Supports up to 250gsm+ | Usually limited to 120gsm |

| Image Quality | Consistent across large areas | Prone to “banding” on thick media |

Frequently Asked Questions

Why is the transfer belt important for transfer paper?

Transfer papers are much heavier and more rigid than standard paper. The transfer belt provides a flat, stable surface and a straight paper path that prevents the thick media from jamming or peeling during the printing process.

How do I know if my transfer belt needs replacing?

Common signs of a failing transfer belt include repeating streaks, ‘ghost’ images from previous prints appearing on the page, or a ‘belt life’ warning on your printer’s display. For transfer printing, even small scratches on the belt can ruin an expensive transfer sheet.

Can I clean the transfer belt myself?

You should generally avoid touching the belt with your hands, as skin oils can ruin the electrostatic properties. If there is loose toner, you can gently blow it away with compressed air, but never use abrasive chemicals or sharp tools.