Transfer Media is a broad category of specialized intermediary materials—ranging from coated papers and transparent films to heat-transfer vinyls—designed to hold a graphic temporarily before it is permanently relocated to a final substrate. Unlike standard paper, transfer media is engineered with specific release agents or thermal adhesives that activate under heat and pressure to “transfer” the design onto textiles, hard goods, or skin.

Read more

Why It Matters: Impact and Use

In the digital decoration industry, selecting the correct transfer media is the foundation of product quality and business ROI (Return on Investment). Demonstrating expertise in media selection is a critical component of E-E-A-T (Expertise, Authoritativeness, and Trustworthiness), as it ensures the decorator can successfully navigate the technical requirements of different surfaces.

- Diversity of Printing Technologies: Transfer media is not universal. It is manufactured with specific coatings to match the “Ink-Acceptance” or “Toner-Fixation” requirements of various hardware:

- Laser/LED Media: Coated to withstand high fuser temperatures.

- Sublimation Media: Porous to allow gaseous ink absorption.

- DTF (Direct-to-Film): PET-based to hold wet ink and adhesive powder.

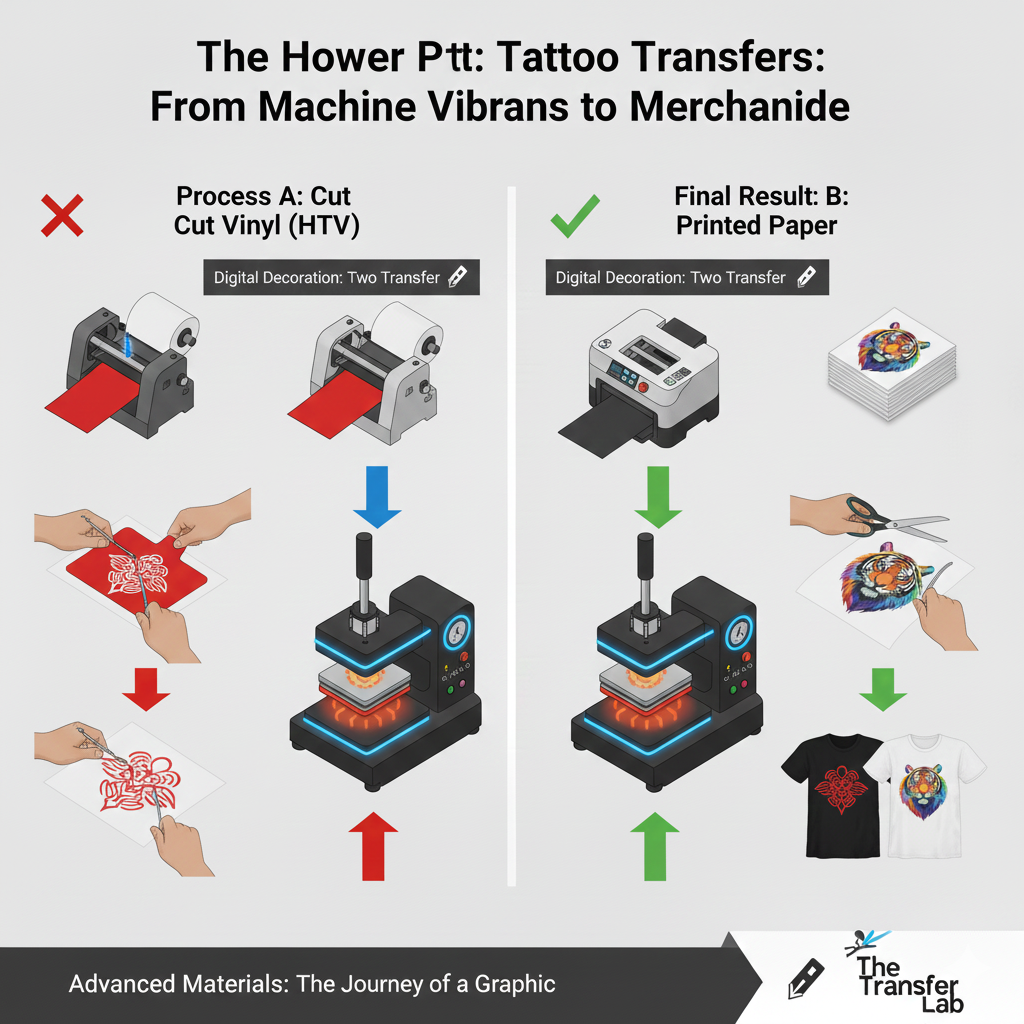

- Cut-Only Media (HTV/Flex): Media isn’t always printed. Heat Transfer Vinyl (HTV) and adhesive vinyl are types of media designed for a cutting plotter. Here, the “image” is created by removing excess material (weeding) rather than applying ink.

- Surface-Specific Solutions: The “Media” choice dictates what you can decorate. Specialized transfer media allows for the branding of items that cannot be printed directly, such as curved mugs, umbrellas, heavy workwear, or dark-colored leathers.

All clamshell Heat Presses

Comparison: Categories of Transfer Media

| Media Type | Process | Common Example | Best For |

| Transfer Paper | Printed (Laser/Inkjet) | TheMagicTouch TTC 3.1 | Cotton Garments |

| Heat Transfer Vinyl | Cut (Plotter) | Flex / Flock | Sports Jerseys (Names/Numbers) |

| Transfer Film | Printed (DTF/Subli) | PET Film | High-Stretch Fabrics |

| Water-Slide Media | Water Activation | TheMagicTouch Tattoo 2.1 | Temporary Tattoos / Ceramics |

Frequently Asked Questions

Is transfer media the same as regular printer paper?

No. While it may look similar, transfer media features technical coatings (polymers or release agents) that allow the image to leave the paper and bond to a new surface when heat is applied. Regular paper would simply burn or stick permanently to the press.

Can I use the same media for both Inkjet and Laser printers?

Generally, no. Laser transfer media is designed to handle high heat from the fuser, whereas Inkjet media is designed to absorb liquid ink. Using the wrong media can damage your printer drums or fuser unit.

What does ‘weeding’ mean in the context of transfer media?

Weeding is the process of removing the ‘negative’ or unwanted areas of the media (usually vinyl or flex) after it has been cut by a plotter, leaving only the desired design on the carrier sheet.