A Transfer Press, commonly referred to as a Heat Press, is a specialized industrial machine designed to apply a precise combination of heat, pressure, and time to a substrate. Its primary function is to activate the adhesives and release agents in transfer media—such as transfer paper, DTF film, or heat transfer vinyl—to permanently bond a graphic onto a product.

Read more

Why It Matters: Impact and Use

The transfer press is the most critical piece of hardware in the customization workflow. While a printer creates the visual, the press determines the durability and professional quality of the final result. In terms of E-E-A-T (Expertise, Authoritativeness, and Trustworthiness), using a calibrated professional press over a domestic iron is what separates a commercial-grade product from a hobbyist one.

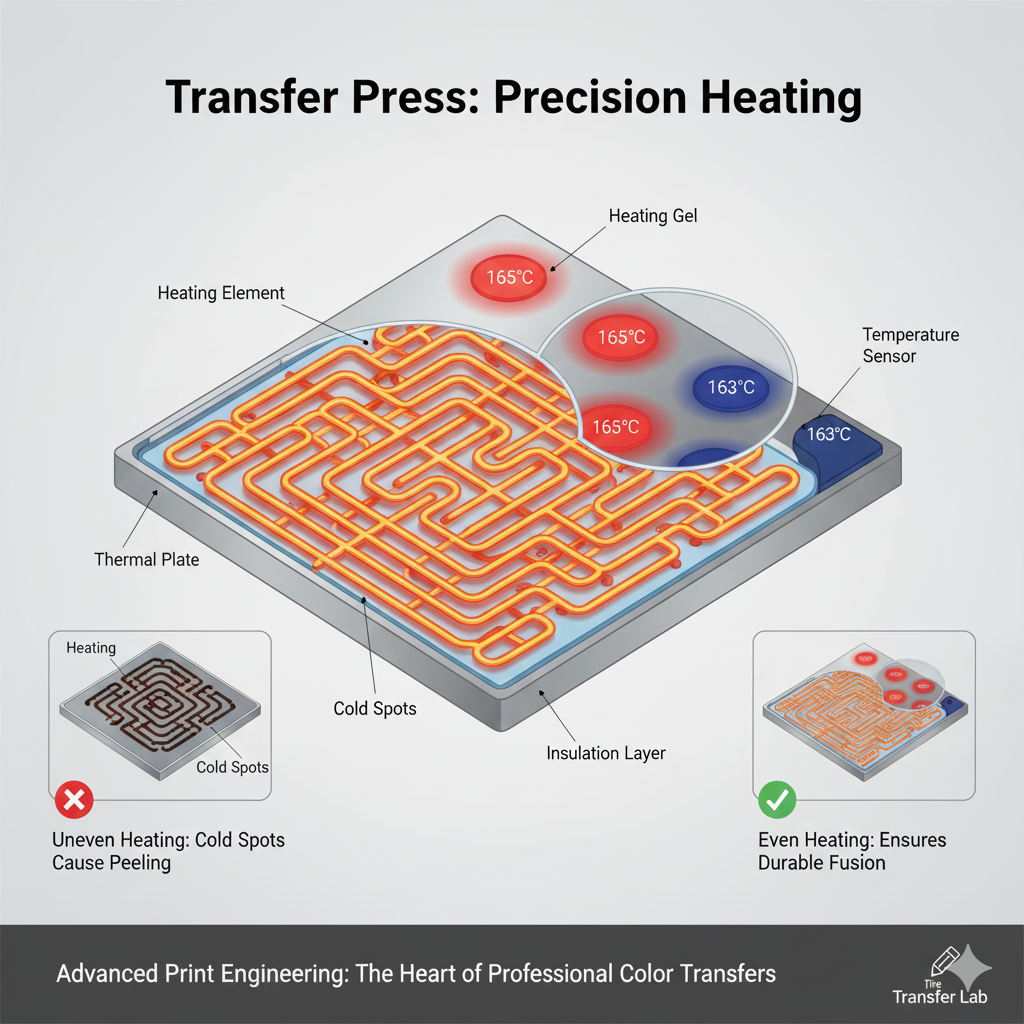

- Precision Calibration: Professional presses allow for exact control over temperature (e.g., 160°C for cotton) and pressure. This ensures that the toner or vinyl “interlocks” with the fabric fibers, which is essential for high wash-fastness and avoiding “peeling” or “cracking.”

- Uniform Heat Distribution: High-quality platens are engineered with dense heating elements to prevent “cold spots.” Inconsistent heat is a leading cause of failed transfers and can negatively impact your ROI (Return on Investment) due to wasted stock.

- Versatility Across Substrates: Beyond standard t-shirts, transfer presses are available in specialized configurations to accommodate different shapes:

- Flatbed Press: For garments, bags, and flat hard goods like wood or metal.

- Cap Press: Featuring a curved platen to match the profile of headwear.

- Mug Press: Utilizing a circular heating element for cylindrical objects like coffee mugs or tumblers.

All clamshell Heat Presses

Comparison: Manual vs. Pneumatic Transfer Presses

| Feature | Manual Heat Press | Pneumatic (Air) Heat Press |

| Operation | Requires physical force to lock/open. | Powered by an air compressor. |

| Pressure Consistency | User-dependent. | Digital and 100% repeatable. |

| Volume Suitability | Low to Medium. | High-volume industrial production. |

| Operator Fatigue | Higher over long shifts. | Minimal; button-operated. |

Frequently Asked Questions

Can I use a household iron instead of a transfer press?

While an iron provides heat, it cannot provide the high, uniform pressure or precise temperature control required for professional transfer media. Using an iron often leads to designs peeling off after the first wash.

Why is ‘Pressure’ so important in a transfer press?

Pressure forces the adhesive or melted toner into the weave of the fabric or the pores of the substrate. Without sufficient pressure, the bond is only superficial and will not be durable.

What are the three variables of a transfer press?

The ‘Big Three’ are Temperature, Time, and Pressure. Every transfer media has a specific ‘recipe’ (e.g., 150°C for 15 seconds at Medium Pressure) that must be followed for a successful application.