Ultra-High Tack refers to the maximum level of initial adhesive strength (grab) found in application tapes and adhesive films. In the world of heat transfer and sign-making, it describes a “high-bond” adhesive formulated to instantly grip surfaces that are textured, porous, or chemically resistant, ensuring that complex graphics can be lifted from their carrier and positioned without slipping or failing.

Read more

Why It Matters: Impact and Use

Selecting the correct “tack” level is a technical decision that directly impacts production speed and waste reduction. Using Ultra-High Tack media is a clear sign of E-E-A-T (Expertise, Authoritativeness, and Trustworthiness), as it demonstrates an understanding of the surface energy of different substrates.

- Precision Registration: The aggressive grab of Ultra-High Tack ensures that once a design is placed, it does not shift. This is vital for Schema (alignment) in multi-layer vinyl applications where even a 1mm offset can ruin the final product.

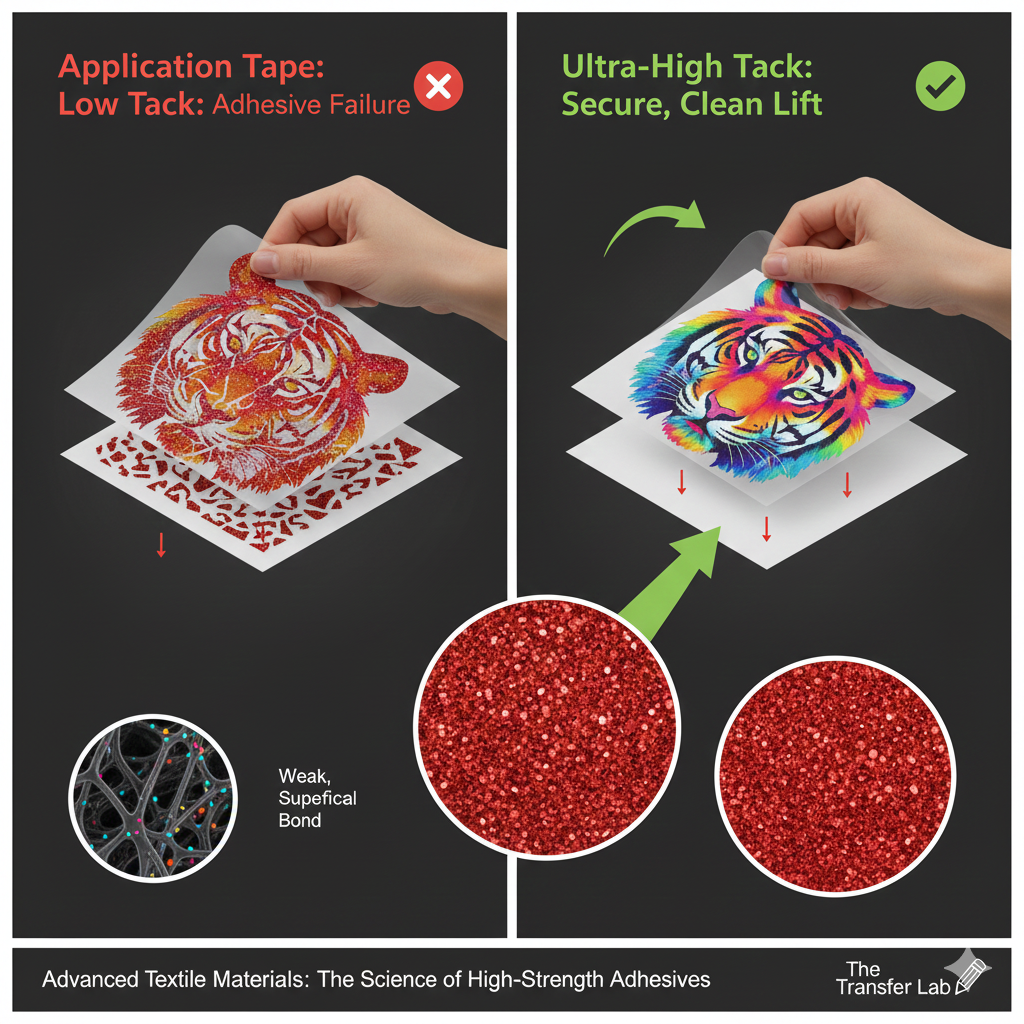

- Handling Difficult Materials: Standard application tapes often fail to grip specialty films like Glitter, Flock, or Brick because of their uneven or textured top surfaces. Ultra-High Tack tapes, such as those used with MagiCut 2Print Glitter White, provide the necessary suction to lift these heavy-duty materials cleanly.

- Production Efficiency: Using a tape that is too weak leads to “lifting failure,” where the design stays stuck to the original carrier. Ultra-High Tack prevents this, allowing for faster weeding and transfer cycles, which improves your overall ROI (Return on Investment).

- Environmental Resistance: Materials labeled as Ultra-High Tack are often designed for “heavy conditions,” such as industrial labeling or outdoor signage on low-energy plastics and powder-coated metals where standard adhesives would peel.

All clamshell Heat Presses

Adhesive Strength Hierarchy

| Tack Level | Best For | Typical Application |

| Low Tack | Delicate surfaces / Large decals | Wall graphics, temporary window clings. |

| Medium Tack | Standard smooth vinyl | General signage, vehicle lettering. |

| High Tack | Small lettering / Matte finishes | Detailed decals, standard Flex films. |

| Ultra-High Tack | Textured & Porous materials | Glitter Flex, Flock, 3D Puff, and rough wood. |

Frequently Asked Questions

When should I use Ultra-High Tack application tape?

You should use it when working with ‘difficult’ materials that have a textured or non-stick surface, such as glitter or flock heat transfer vinyls. Standard tapes lack the adhesive strength to lift these materials from their backing.

Can an adhesive be ‘too’ strong?

Yes. If you use Ultra-High Tack on a standard smooth vinyl or a delicate wall, it may be nearly impossible to remove the application tape without damaging the design or the substrate. Always match the tack level to the material texture.

Does Ultra-High Tack leave a residue?

Professional-grade Ultra-High Tack tapes are engineered to have high ‘cohesion,’ meaning the glue stays on the tape and not on your design, even though the bond is very strong.