Warm Peel refers to a specific technique in the heat transfer process where the carrier sheet (also known as the liner or backing) is removed after the garment has had a brief period to cool, but while it still retains significant residual heat. It sits technically between a Hot Peel (immediate removal) and a Cold Peel (removal only after the substrate is completely cold to the touch).

Read more

Why It Matters: Impact and Use

In the professional garment decoration industry, following the correct “peel” instruction is the difference between a perfect retail finish and a ruined product. Mastering these nuances is a hallmark as it ensures the adhesive bond is fully set before the tension of the carrier removal is applied.

- Adhesion Stabilization: For certain transfer media, like TheMagicTouch T.One, the polymer coating needs a few seconds to “set” into the fabric fibers. Peeling too hot might pull the image back up (delamination), while peeling too cold might cause the carrier to stick too aggressively to the toner.

- Production Efficiency: A Warm Peel is often the “sweet spot” for high-volume shops. It allows the operator to move the garment to a cooling station for 5–10 seconds, maintaining a faster ROI (Return on Investment) than a Cold Peel, which requires waiting several minutes per item.

- Technical Precision: The term is frequently used in technical data sheets. Misinterpreting a “Warm Peel” instruction as a “Hot Peel” is a common cause of high waste rates in production environments.

All clamshell Heat Presses

Comparison: Peel Temperature Profiles

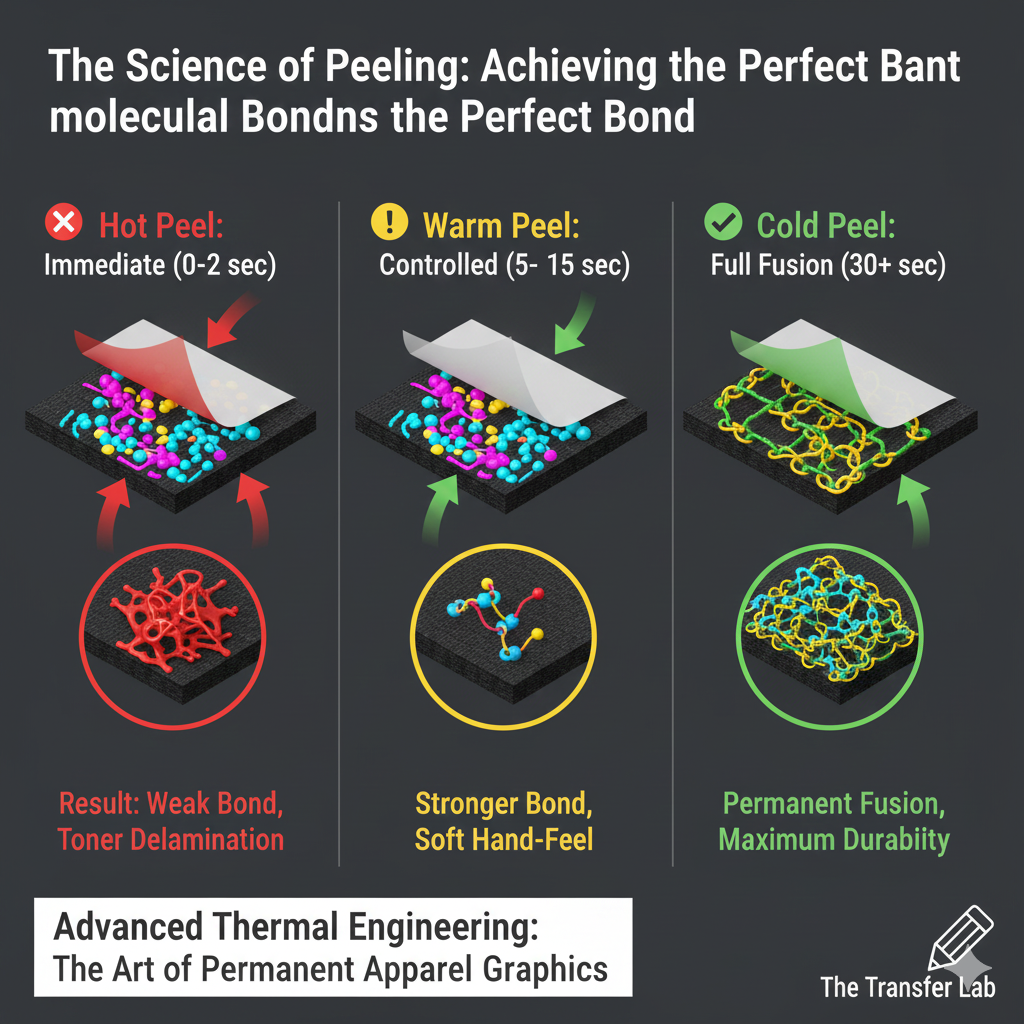

| Peel Type | Timing | Best For | Risk if Wrong |

| Hot Peel | Immediate (0–2 seconds) | Standard Flex / Vinyl | Design may “shrink” or distort. |

| Warm Peel | 5–15 seconds cooling | TheMagicTouch T.ONE, Specialty Films | Incomplete transfer or “ghosting.” |

| Cold Peel | 30+ seconds (Stone cold) | TheMagicTouch CPM 6.2, Dark Garment Transfers | Carrier sticks permanently to the design. |

Frequently Asked Questions

On what applications is a warm peel common?

On many modern polyurethane (PU) flex films and some DTF (Direct-to-Film) applications a warm peel is utilized to achieve a softer finish and better registration.

What happens if I peel a Warm Peel transfer while it’s still hot?

Peeling too early can lead to ‘adhesive failure,’ where parts of the design remain on the carrier sheet because the glue hasn’t had enough time to anchor into the fabric.

Is T.One the only paper that uses a warm peel?

No, many modern polyurethane (PU) flex films and some DTF (Direct-to-Film) applications also utilize a warm peel to achieve a softer finish and better registration.