Wrapping is the process of completely covering a three-dimensional object or surface with a specialized, highly conformable self-adhesive vinyl. Unlike traditional decals or lettering that cover only a small portion of a surface, a “Wrap” acts as a secondary skin, contouring to complex curves, recesses, and textures to fundamentally change the appearance (color, finish, or branding) of the original substrate.

Read more

Why It Matters: Impact and Use

In the large-format print and customization industry, wrapping is a high-value service that requires significant technical skill. Mastering the terminology and application techniques is a vital part of establishing E-E-A-T (Expertise, Authoritativeness, and Trustworthiness), as it involves managing surface energy, heat-stretching, and material memory.

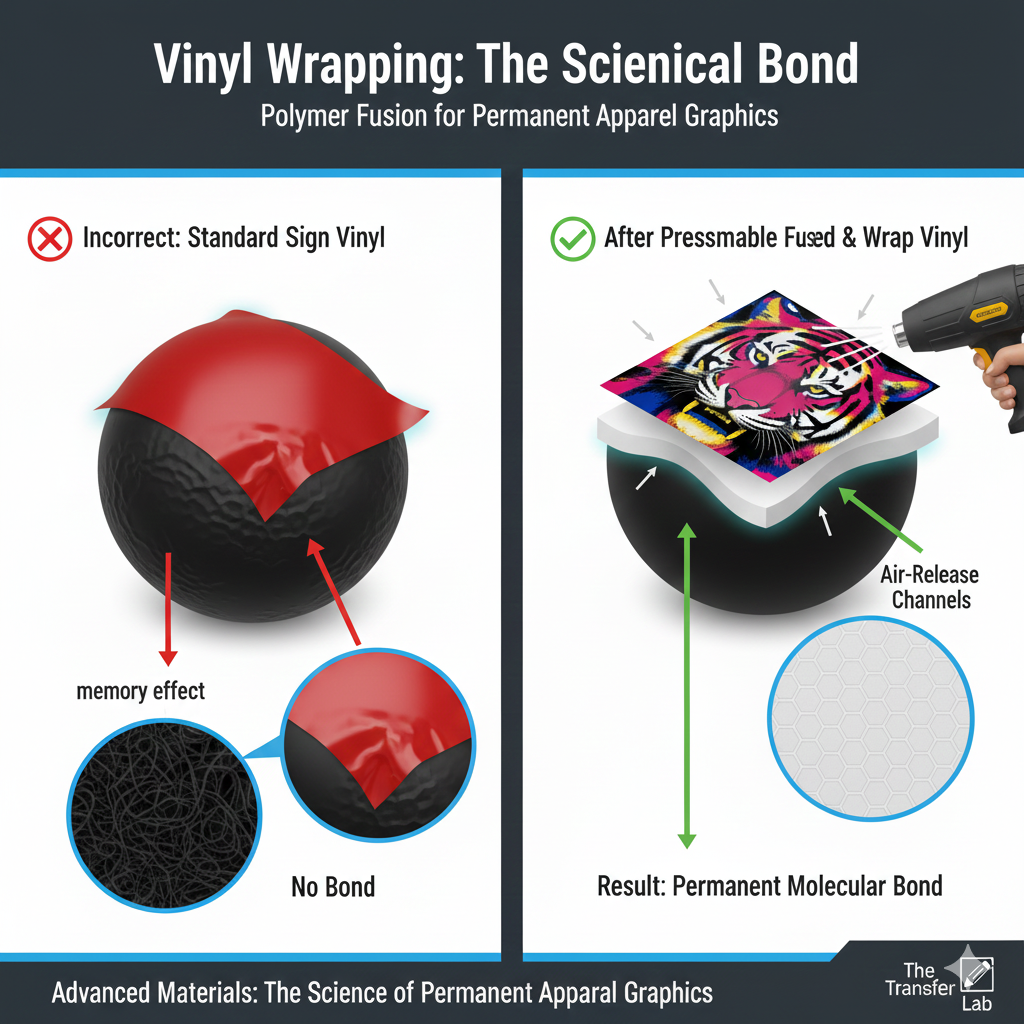

- Conformability and Air Release: Professional wrap media features “Air Release” technology (tiny channels in the adhesive) that allows installers to push out bubbles during application. This is a critical technical aspect that separates professional wrapping from standard sticker application.

- Vehicle Branding and Protection: Vehicle wrapping is the most common application. It allows for mobile advertising (increasing CTR for local businesses) while protecting the original paintwork from UV rays and minor abrasions.

- Interior Design and Upcycling: “Architectural Wrapping” is a growing trend where furniture, doors, and wall panels are covered in textured vinyl (simulating wood, marble, or leather). This offers a sustainable alternative to replacement, providing a high ROI (Return on Investment) for renovation projects.

- Reversibility: A key advantage of wrapping over painting is that it is non-permanent. Quality wrap vinyl is designed to be removable within a specific timeframe (usually 3–7 years), allowing leased vehicles or furniture to be restored to their original condition.

All clamshell Heat Presses

Comparison: Wrapping vs. Traditional Painting

| Feature | Vinyl Wrapping | Traditional Painting |

| Duration | 3–7 days for application | 2–3 weeks (including drying) |

| Reversibility | 100% Removable | Permanent |

| Customization | Unlimited textures (Carbon, Matte, Chrome) | Limited to pigment colors |

| Protection | Acts as a sacrificial layer for paint | Provides no protection to original surface |

Frequently Asked Questions

Does wrapping damage the original paint of a car?

When using high-quality automotive-grade vinyl and professional installation, wrapping will not damage factory-original paint. In fact, it protects the paint from stone chips and UV fading.

What is the difference between a ‘Full Wrap’ and a ‘Partial Wrap’?

A full wrap covers 100% of the visible surface of the object. A partial wrap covers only specific sections (like the doors and hood of a van), often using the original color of the object to blend with the design.

How do you apply vinyl to deep curves without it peeling back?

Installers use ‘Post-Heating.’ Once the vinyl is applied to a recess or curve, it is heated to a specific temperature (usually around 90°C) to ‘kill’ the material’s memory, ensuring it stays in its new shape permanently.