Are you a garment decorator, a custom t-shirt business owner, or a craft entrepreneur striving for a professional finish that truly lasts? If you work with heat transfers, especially DTF (Direct to Film) or white toner papers like TheMagicTouch WoW or T.ONE, you know the final press is everything. Enter TheMagicTouch T.Seal, a reusable silicone sheet that isn’t just another finishing paper—it’s the key to achieving unparalleled washability, softness, and stretchability in your decorated apparel.

Read more

What is TheMagicTouch T.Seal? (And Why You Need It)

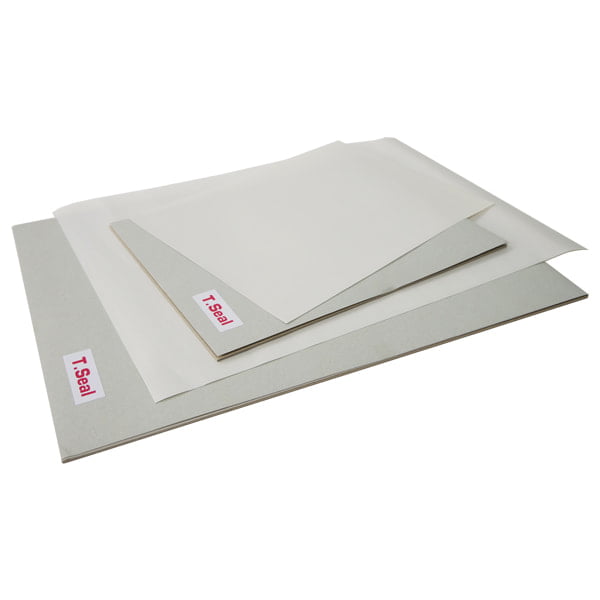

TheMagicTouch T.Seal is a specialized, reusable silicone sheet with a unique flexible, gridded coating designed for the post-pressing of your heat transfers. While a standard release paper can protect your press platen, the T.Seal does much more than just cover the print.

Its innovative design is engineered to fundamentally change the way your transfer adheres to the fabric.

Key Benefits: The T.Seal Advantage

This is where the T.Seal truly shines, delivering a massive boost in the three most critical areas for any decorated garment:

- Next-Level Durability and Washability: The T.Seal’s special coating helps to physically embed the transfer deeper into the textile fibers. This superior adhesion means the print is less likely to lift or peel, resulting in a significantly enhanced washability (often cited to last 50-60+ washes with white toner prints).

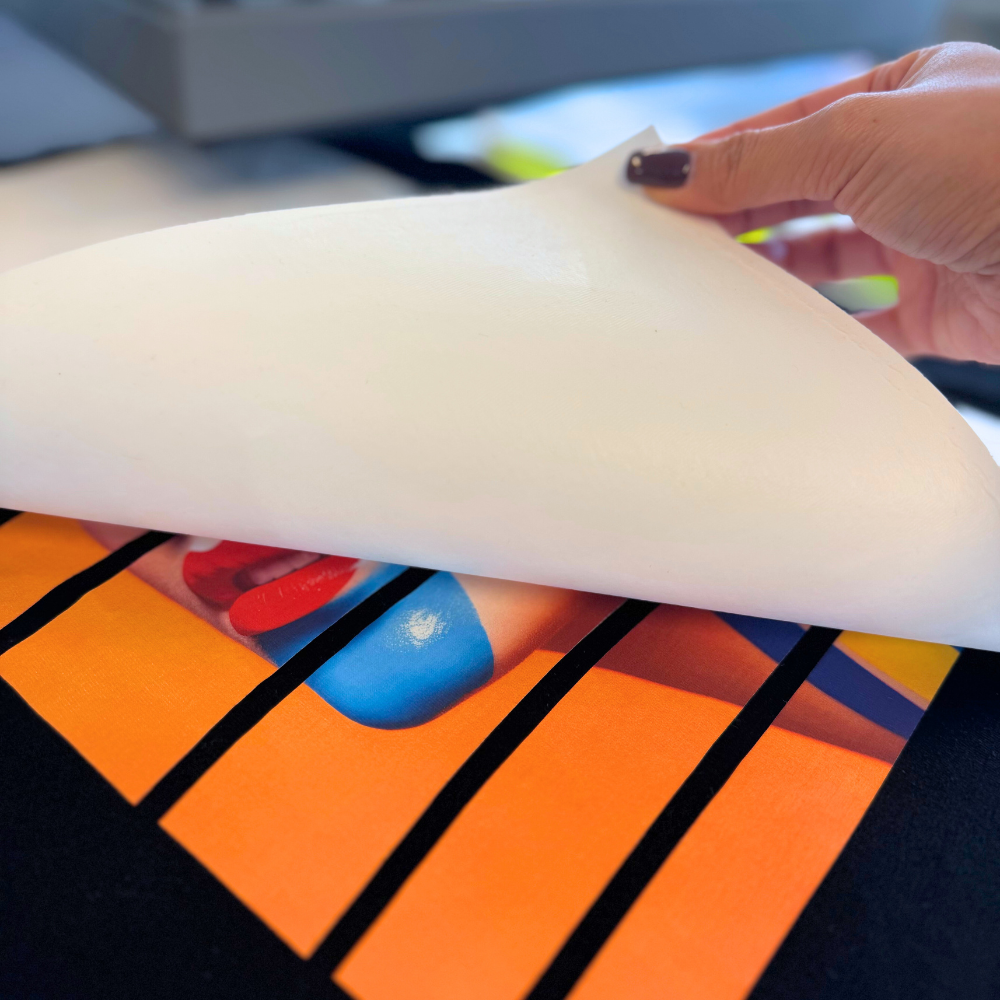

- Superior Soft Hand Feel: By pushing the toner or ink deeper into the fibers, the print doesn’t feel like it’s sitting on the fabric. This process dramatically reduces the “plastic” or vinyl-like texture, giving you a smooth, soft, and high-quality finish—a huge factor in customer satisfaction.

- Improved Stretchability & Crack Resistance: Garments need to move. The flexible coating promotes better stretching with the fabric, which is essential for preventing cracking and tearing on the final print, especially on materials like cotton and blends.

The T.Seal is the Ultimate DTF Finishing Tool

While it works wonders with TheMagicTouch’s own transfer papers, the T.Seal has become a game-changer in the Direct to Film (DTF) community. Applying it as a final press step after peeling your DTF transfer helps to matte the finish and secure the ink and powder firmly into the garment’s weave, maximizing your print’s lifespan and professional look.

How to Use Your T.Seal for a Professional Finish

Using the T.Seal is a quick and simple step that should be integrated into your post-press workflow:

| Step | Action | Details |

| 1. Primary Press | Complete your initial heat transfer press and peel (hot or cold, depending on your transfer paper/DTF film). | |

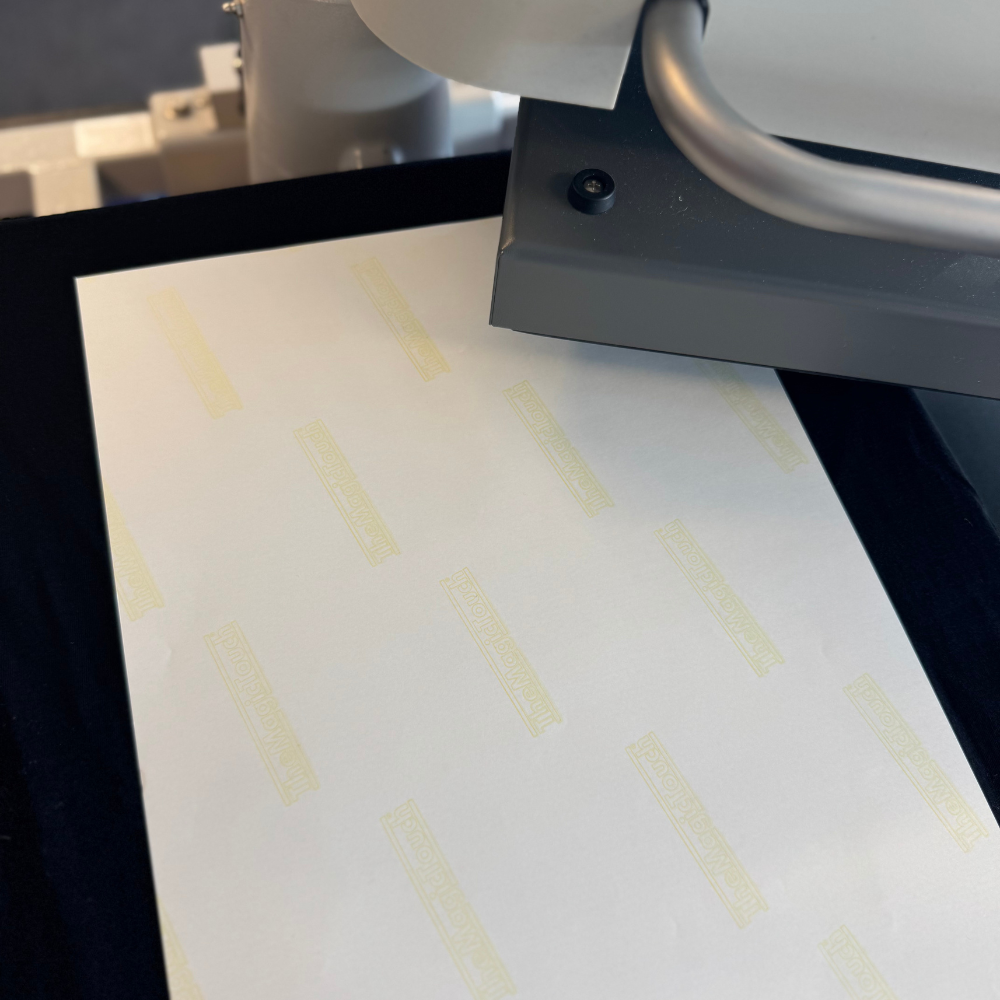

| 2. Position T.Seal | Place the T.Seal sheet over your newly applied print. Ensure the side with the rubbery/gridded coating is directly facing down onto the transfer. | This is the crucial side! |

| 3. Post-Press | Press with High Pressure for 15-20 seconds (check your specific T.Seal instructions for optimal temperature, often around 150°C/290°F. | Use high, firm pressure. |

| 4. Reveal | Remove the T.Seal while it is lukewarm to cold. | You’ll see the difference immediately—a beautiful, soft matte finish. |

Pro Tip for Longevity: Your T.Seal is reusable (up to 100+ times, depending on the application)! If the coating gets rough or contaminated, press it on a blank sheet of paper for 15 seconds once or twice to refresh the surface.

How TheMagicTouch T.Seal increases the washability of your printsWatch the T.Seal Boost Your DTF Prints

To truly see the difference the T.Seal makes, watch this excellent walkthrough from AAPrintSupplyCo. This video focuses specifically on using the T.Seal to finalize your Direct to Film (DTF) transfers, demonstrating the resulting increase in durability, stretchability, and overall hand feel.

- Why Post-Press Matters: Learn why the post-press step with the T.Seal is essential for achieving a high-quality finish [00:32].

- The T.Seal Difference: See how the rubber-coated side of the T.Seal adapts to the grooves and weaves of the garment fiber, sealing the transfer in for higher durability [00:44].

- Conditioning Your T.Seal: Discover the critical one-time step of conditioning your T.Seal in the heat press to ensure it lasts for hundreds of presses [01:11].

- Temperature Guide: Get the essential tip: never press the T.Seal above 300°F (149°C/290°F) being the recommended temperature for the final seal [03:03].

- Proof of Adhesion: Observe the clear impressions of the fabric’s weave showing through the finished print, which is a tell-tale sign of a strong, permanent bond and excellent washability [03:52].

Watch the full guide here:

Conclusion: Invest in Print Quality

In a competitive market, print quality and durability are what separate the professionals from the hobbyists. TheMagicTouch T.Seal is a small investment that delivers a huge return in the form of elevated quality, increased heat transfer durability, and happier customers. If your goal is to offer T-shirts and apparel with the best washability and a soft, non-plasticky feel, adding the T.Seal to your DTF finishing or white toner process is a non-negotiable step.

Get Your T.Seal and Boost Washability Today

Frequently Asked Questions

What is TheMagicTouch T.Seal used for?

TheMagicTouch T.Seal is a reusable, specialized silicone finishing sheet used to post-press heat transfers (like DTF and white toner prints) onto textiles. Its primary purpose is to dramatically increase the washability, improve heat transfer durability, and create a professional, soft, matte finish on the final garment.

Watch our collegue Joseph from TheMagicTouch USA talk about TheMagicTouch T.Seal

Is TheMagicTouch T.Seal reusable, and how many times can I use it?

Yes, the T.Seal is highly reusable. With proper care, a single sheet can typically be used for 100+ applications. This makes it a very cost-effective tool for consistent DTF finishing and maximizing the lifespan of your prints.

Does the T.Seal work for DTF (Direct to Film) transfers?

Absolutely! The T.Seal is an ideal tool for DTF finishing. After peeling your DTF film, pressing the transfer one final time with the T.Seal helps mat the shine, fully embed the powder/ink into the fabric, and optimize the print for superior washability and stretch.

How long and at what temperature should I press with the T.Seal?

After the initial transfer, the T.Seal is typically pressed onto the print for 15-20 seconds at a medium-high temperature, usually around 150°C/290°F, using high pressure. Always check the specific instructions for your transfer material to ensure the best results for durability.

Why do my transfers crack, and can the T.Seal help?

Transfers often crack due to poor adhesion or a lack of flexibility. The T.Seal helps by pushing the transfer material deeper into the textile fibers, securing the bond and providing a more flexible coating. This process significantly improves crack resistance and overall heat transfer durability on high-stretch garments.