Your basket is currently empty!

Buy the Cheapest DTF Printer A3 in Europe

Learn more about the fantastic features of the DTF Magic Printer Pro 30.

Easy to maintain

Direct to Film (DTF) needs maintenance. But we’ve made it as easy as possible.

Compact

Small in size, big in performance – perfect for any small space and smaller volumes.

Low investment

Benefit from a low investment and do not take a big risk by investing too much in this new printing technique.

High margin

Discover the low printing costs of Direct to Film (DTF) and use this printing technique for multiple purposes.

DTF Magic Printer Pro 30

A compact and affordable 30cm desktop DTF printer with a single print head. This user-friendly, specially designed model features a high-density Epson original DX11 print head for vibrant full-color or single-color transfers on A3+ or 30cm roll DTF Magic Films.

- Automatic wink circulation

- Print head anti-collision system

- Awaste ink and ink shortage alarm

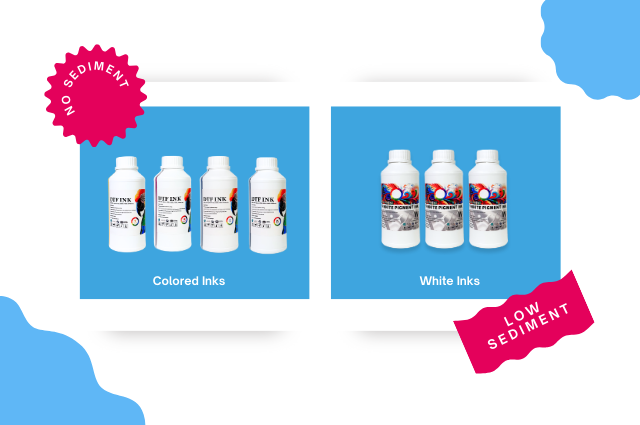

Low sedimentation DTF white ink

The white ink sedimentation is 70% less than regular white ink! The standby time is 15 hours on the printer and you don’t need to clean the printhead when you turn off the printer. The white coverage has a shelf life of 12 months and remains in good condition.

Specifications:

- Patented ink technology & OEKO-TEX certified

- Shelf life of up to 12 months!

- Low sediment to minimize nozzle clogging

DTF Powder

A special adhesive powder that melts under the influence of heat and forms an adhesive bridge between the print and the textile. The adhesive powder is applied to the DTF print after printing. This is done manually (a powder shaker is optionally available).

Specifications:

- Excellent adhesion to textiles, cotton or mixed materials

- Super soft to the touch and high quality print

- Easy to process and excellent washing results

DTF Magic Films

With the introduction of the new DTF Films under the new brand DTF Magic, you will immediately get the most impressive and amazing features:

Specifications:

- Vibrant and highly detailed DTF prints

- One-step transfer – Hot Peel application

- A3+ sheets ( 30×45 cm) or on a roll 30 cm available.

DTF Magic Software Lite

More than just RIP software, DTF Magic Software Lite offers high-fidelity color printing and professional job preparation and management tools to streamline your production workflow from start to finish.

Specifications:

- A combination of file preparation tools

- Perfect color management for all your images

- Use production automation for pure speed

FAQ

What is a DTF printer?

A DTF (Direct to Film) printer prints designs onto a special film, which is then transferred to fabric using heat and bonding powder. This printer is popular for printing on a wide variety of materials, including cotton, polyester, blended fabrics, leather, and more.

How is DTF printing different from DTG (Direct to Garment) printing?

While DTG prints directly onto fabric, DTF prints onto foil first and then transfers the design onto the fabric. DTF is generally more versatile in terms of material types and colors.

What materials can I print on with a DTF printer?

You can print on cotton, polyester, blended fabrics, nylon, silk, leather, denim and more. It works well on both light and dark fabrics.

What equipment do I need for DTF printing?

- A DTF printer

- DTF inks

- PET film

- Hotmelt powder (glue powder)

- Heat press machine

Do I need to pre-treat the fabric before applying a DTF print?

No. One of the advantages of DTF is that you don’t have to pre-treat the fabric like you do with DTG printing.

How sustainable are DTF prints?

DTF prints are highly durable, flexible and can withstand many washes without cracking or fading if applied correctly.

What kind of maintenance do DTF printers require?

Regular maintenance includes cleaning print heads, performing nozzle checks, keeping the printer dust-free, and properly storing ink and film.

How long does the transfer process take?

The heat press transfer process usually takes about 15-20 seconds at around 160-170°C (320-340°F), depending on the material.

Are DTF prints safe for skin contact?

Yes, when using certified non-toxic inks and powders, DTF prints are safe for skin contact.

Can I use a regular inkjet printer for DTF printing?

No, for DTF you need a special printer or a custom inkjet printer with compatible DTF inks and settings.

How much does it cost to print with DTF?

Costs vary depending on ink usage, film, powder and machine size, but DTF is generally considered cost effective for both short and large production runs.

What are common problems with DTF printing?

Problems can include ink clogging, film sticking issues, poor adhesion if too little powder is used, or colors not appearing vibrant if settings are not optimized.

What software is needed for DTF printing?

Most DTF configurations require Raster Image Processor (RIP) software such as Acrorip, Cadlink or EKPrint Studio for white ink layering and colour management.

Can DTF prints be ironed?

Yes, but it is recommended to iron them inside out or put a protective cover over the print to maintain the quality.