Are you fascinated by the world of personalization and eager to unleash your creativity on textiles, mugs, or other surfaces? If so, you’ve likely heard of transfer paper. At TheMagicTouch, we specialize in delivering high-quality transfer solutions that help you achieve professional results. In this blog post, we’ll dive deep into the world of transfer paper, explain how it works, and give you valuable tips for a flawless application.

Read more

What is Transfer Paper and How Does It Work?

Transfer paper is a specially coated paper designed to transfer an image or text onto another surface, typically using heat and pressure. This process is called “transferring.” There are various types of transfer paper, each optimized for specific materials and printers (inkjet, laser). The coating on the paper reacts to the heat, allowing the ink or toner to permanently adhere to the target surface.

The Advantages of Working with Transfer Paper

Transfer paper is a specially coated paper designed to transfer an image or text onto another surface, typically using heat and pressure. This process is called “transferring.” There are various types of transfer paper, each optimized for specific materials and printers (inkjet, laser). The coating on the paper reacts to the heat, allowing the ink or toner to permanently adhere to the target surface.

- Personalization: Create unique gifts, corporate wear, or promotional items.

- Flexibility: Apply designs to a wide range of materials such as cotton, polyester, wood, ceramic, and metal.

- Cost-Effective: An economical way to produce small to medium-sized runs.

- Ease of Use: With the right instructions, anyone can work with it.

Step-by-Step: The Basic Principles of Transferring

While the exact steps may vary depending on the type of transfer paper and application, here are the general basic principles:

1. Choose the Right Paper

This is crucial! Make sure you select TheMagicTouch transfer paper that is suitable for your printer (laser) and the surface you want to print on (light or dark textiles, hard substrates).

2. Prepare the Design

While the exact steps may vary depending on the type of transfer paper and application, here are the general basic principles:

Prepare the Design: Create your design in TheMagicTouch software. Choose TheMagicTouch software Basic (CMYK printers) or TheMagicTouch software Pro (CMYW) or other graphic software. Note: When you don’t use a software, you can probably use the standard printer driver.

3. Print: The Basic Principles of Transferring

While the exact steps may vary depending on the type of transfer paper and application, here are the general basic principles:

Print: Print your design onto the correct side of the transfer paper. Always consult the specific transfer paper’s instructions for the right printer settings.

Cut Out (Optional): Trim away any excess paper around your design. This can be done manually with scissors or with a cutting plotter for precision.

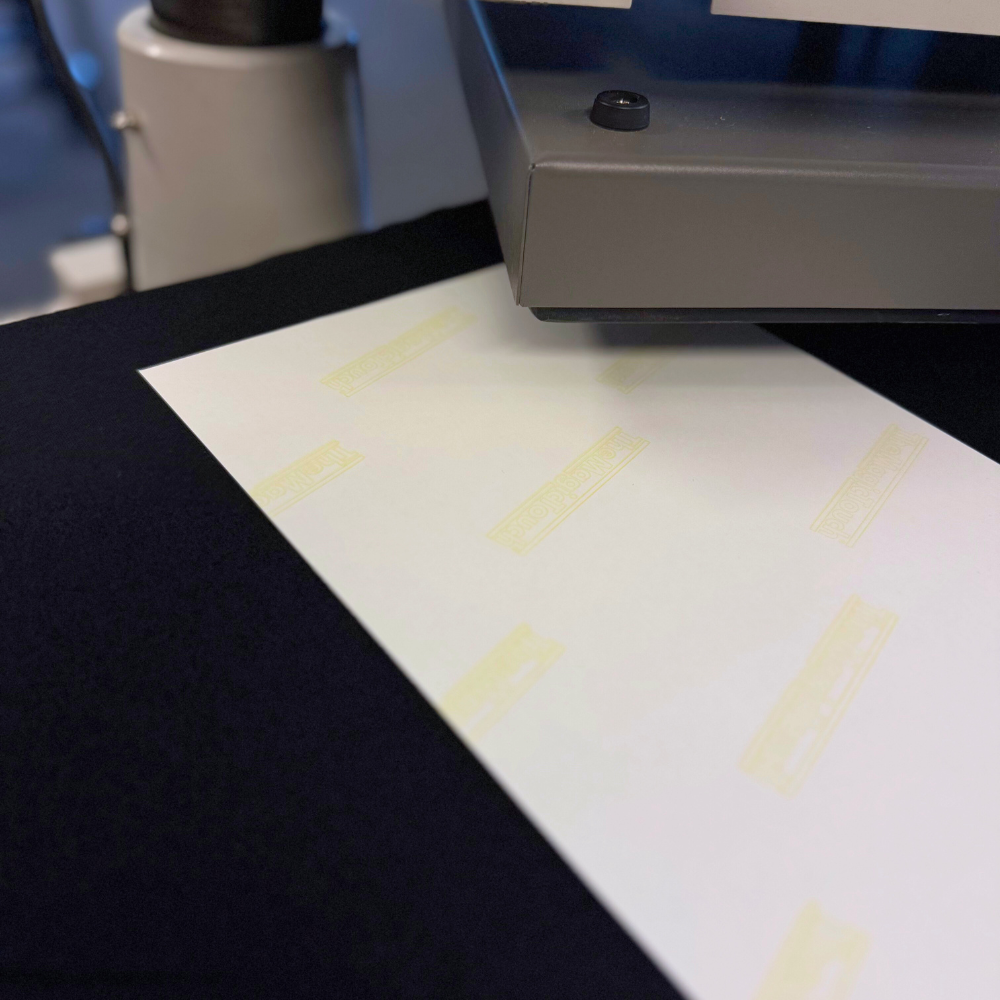

Prepare the Surface: Ensure the surface is clean, dry, and wrinkle-free. Pre-press textiles with a heat press to remove moisture.

Transfer: Place the transfer paper, printed side down, onto the target surface. Use a heat press (recommended) or an iron to transfer the design. The temperature, time, and pressure are essential and listed in the transfer paper’s instructions.

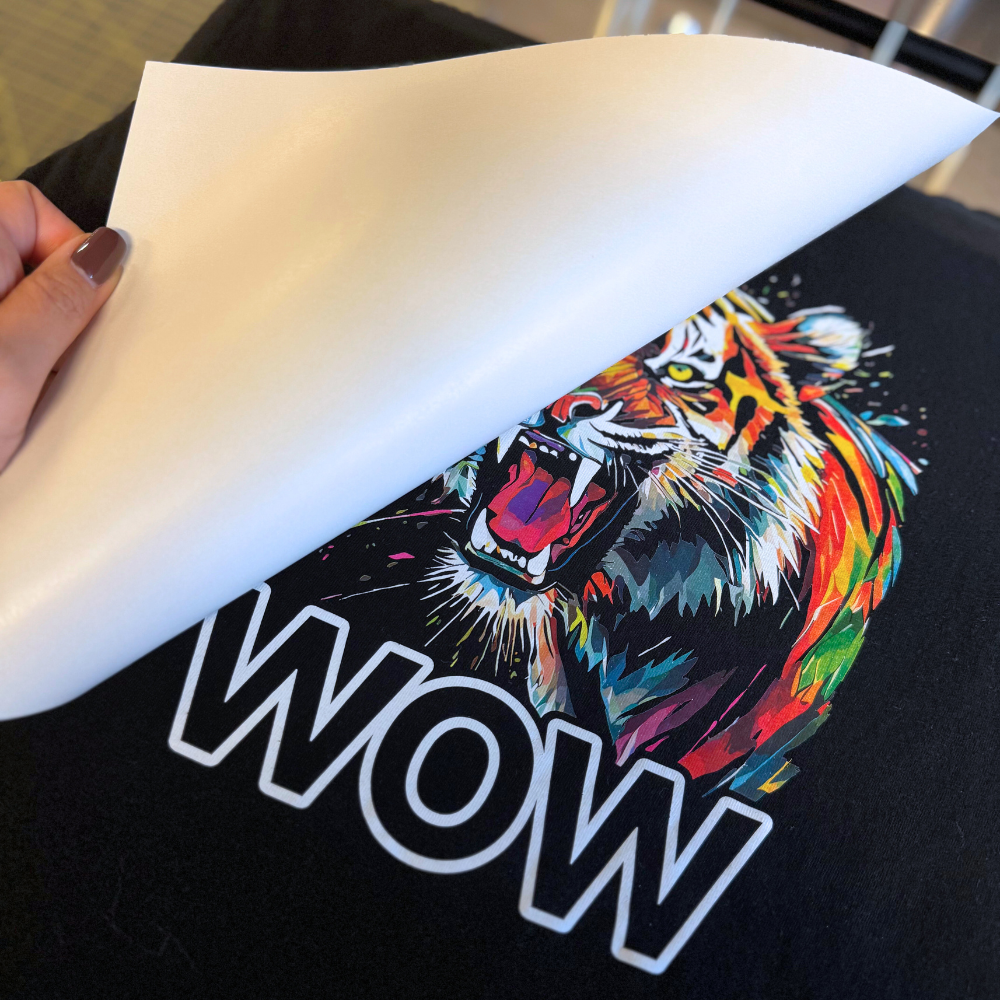

Remove the Backing: Once the transfer process is complete, carefully peel off the backing (carrier sheet) of the transfer paper. This can be done hot or cold, depending on the type of paper.

Tips for Perfect Results

Read the Instructions: This may seem obvious, but every type of TheMagicTouch transfer paper has specific instructions. Read them carefully!

Always Test: Always perform a test on a scrap piece of your material, especially when working with a new product or design.

Use a Heat Press: For the best and most consistent results, we recommend using a heat press. This ensures even temperature and pressure.

The Right Temperature, Time, and Pressure: These are the three pillars of a successful transfer. Make sure you follow the recommended settings.

Maintenance: Inform your customers about the proper care for the transferred products (e.g., washing instructions for textiles) to maximize their lifespan.

Why Choose TheMagicTouch Transfer Paper?

At TheMagicTouch, we have been the expert in transfer solutions for years. Our transfer paper is known for its high quality, durability, and ease of use. Whether you are a beginner or an experienced professional, we have the right transfer paper for your project. Discover our extensive range and be inspired by the endless possibilities of personalization.

What is the main difference between transfer paper for light and dark fabrics?

Transfer paper for light fabrics is generally translucent, meaning the color of the fabric will show through. It relies on the white color of the fabric to maintain the vibrancy of the design. Transfer paper for dark fabrics has an opaque (white) base layer that is printed, ensuring the design’s colors remain true and pop against the dark background.

Do I need to mirror my design before printing?

Yes, for most textile transfers, especially those involving heat presses, you must mirror (flip) your image horizontally before printing. The main exception is the paper designed for dark fabrics (which is often peeled hot or cold), but you should always check the specific instructions for your TheMagicTouch paper to be certain.

Can I use a regular home iron instead of a heat press?

We strongly recommend a heat press. A heat press provides even, consistent heat and pressure across the entire design, which is essential for a professional, durable result. An iron often results in inconsistent transfers and poor wash fastness.

How long do designs transferred with TheMagicTouch paper usually last?

When properly applied using the correct temperature, time, and pressure, and following the care instructions (washing inside out, cold cycle, no harsh detergents), transfers can be very durable, often lasting for the typical lifespan of the garment itself. Durability depends on the specific paper used and adherence to the application steps.

Can I transfer designs onto non-fabric items like mugs or wood?

Absolutely! TheMagicTouch offers specialized transfer papers for hard substrates like ceramics (mugs, tiles), wood, metal, and glass. These are often different from the textile papers and require a different set of press parameters (sometimes higher temperature and longer time). Look for our specific papers designed for hard surfaces.