Hotmelt Powder is a granular adhesive made from ground TPU (Thermoplastic Polyurethane) or polyester particles. Specifically engineered for the Direct to Film (DTF) workflow, this powder is applied to wet pigment ink on a PET film.

Read more

Why It Matters: Impact and Use

Hotmelt powder is the “bridge” between digital ink and physical fabric. In a professional printing environment, the choice and application of this powder are critical indicators of E-E-A-T (Expertise, Authoritativeness, and Trustworthiness), as it dictates the stretch, softness, and durability of the final garment.

Wash-Fastness: The chemical bond formed by TPU hotmelt powder is highly resistant to water and detergents. A correctly applied DTF transfer can typically withstand 50+ industrial wash cycles without cracking or delaminating.

Selective Bonding: The powder is chemically formulated to adhere only to the wet textile ink and not the surrounding DTF Film. This allows for “no-weed” transfers, meaning complex logos and fine text can be applied without manual cutting or weeding.

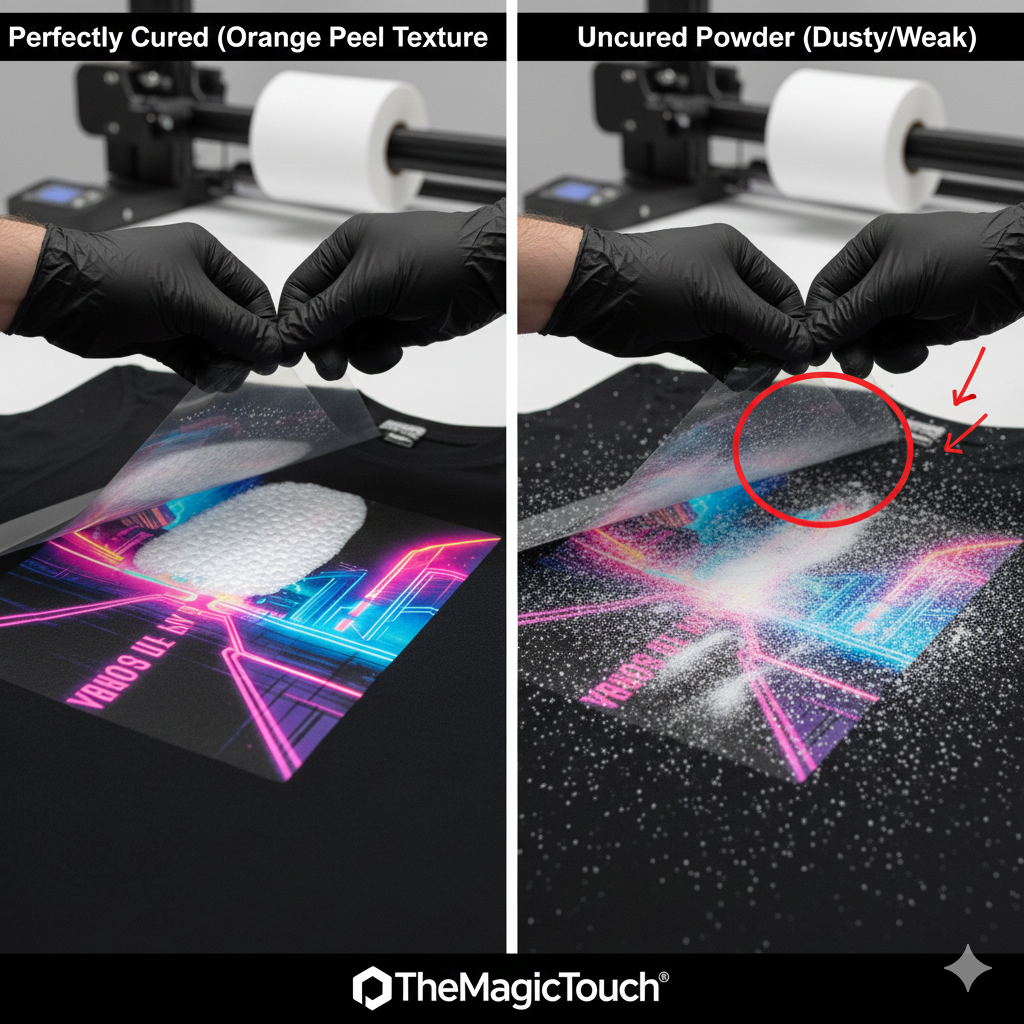

The Gelling Process: Once applied, the powder must be “cured” (usually at 110°C–150°C). This turns the granular dust into a smooth, tacky layer. If under-cured, the transfer will peel; if over-cured, the adhesive may become brittle.

Soft “Hand-Feel”: High-quality hotmelt powders are designed to be extremely fine. This ensures that even large printed areas remain soft and flexible on the shirt, rather than feeling like a thick plastic sheet.

Technical Specifications: Fine vs. Coarse

| Powder Grade | Particle Size | Best Use Case | Benefit |

| Fine (Digital) | 0–80 µm | Small text, thin lines, light fabrics. | Superior softness and high detail. |

| Medium | 80–170 µm | General t-shirt printing (Standard). | Balanced durability and flexibility. |

| Coarse | 150–250 µm | Heavy workwear, canvas, denim. | Maximum adhesive “bite” for rough textures. |

Frequently Asked Questions

Why isn’t the DTF powder sticking to my print?

This usually happens if the ink has dried too much before the powder was applied. In DTF printing, the powder must be applied while the ink (especially the white underbase) is still wet to ensure total coverage.

Can I reuse the excess DTF powder?

Yes. One of the efficiencies of the DTF process is that excess powder that doesn’t stick to the ink can be collected and returned to the container for future use, provided it remains clean and dry.

How do I know when the hotmelt powder is correctly cured?

Correctly cured powder should look like ‘melted sugar’ or an even orange-peel texture. It should no longer look like dry dust, but it should not be so melted that it becomes completely flat and loses its adhesive properties.