Monomer (or Monomeric Vinyl) refers to a type of pressure-sensitive PVC film constructed using short-chain plasticizers. During the manufacturing process, the vinyl paste is spread through rollers (calendared) to create a thin sheet. Because the plasticizer molecules are small and unlinked, they are more prone to “migration” and degradation when exposed to external elements.

Read more

Why It Matters: Impact and Use

In the signage and graphics industry, distinguishing between Monomer and Polymer films is a fundamental technical skill. Recommending the correct film for a client’s budget and timeline is a key indicator of E-E-A-T (Expertise, Authoritativeness, and Trustworthiness).

- UV Sensitivity: The chemical structure of a monomer is more susceptible to sunlight. Over time, the film may become brittle and the colors will fade faster than in higher-grade films.

- Short-Term Cost Efficiency: Monomeric vinyl is significantly cheaper to produce than polymeric or cast alternatives. This makes it the ideal choice for high-volume, short-term applications where a long lifespan is not required.

- Ideal for Temporary Campaigns: With an outdoor lifespan of 2 to 5 years, Monomer is the “go-to” material for indoor POS displays, short-term exhibition graphics, and temporary promotional window stickers.

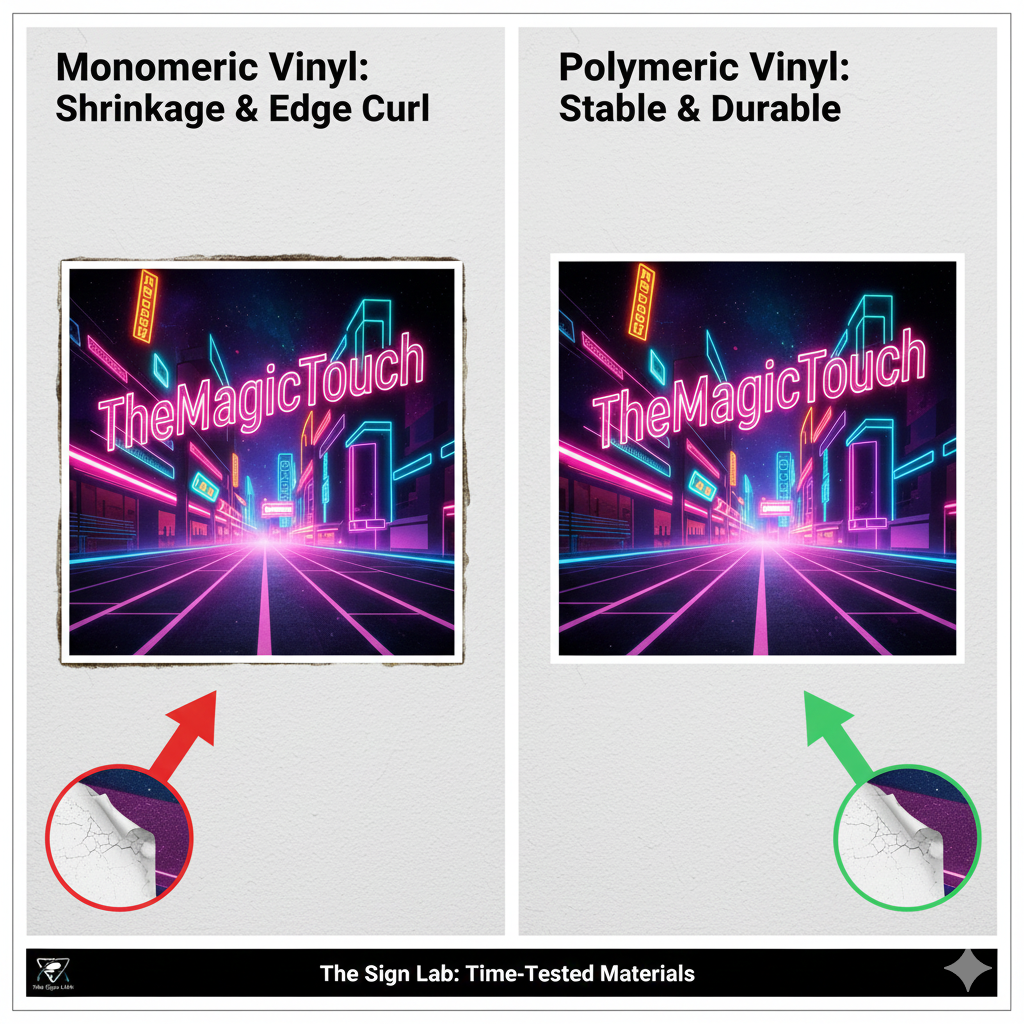

- The “Shrinkage” Factor: Because the plasticizers in Monomeric vinyl are less stable, the film has a tendency to shrink over time when exposed to UV radiation. This can result in a visible “adhesive border” around the edges of the graphic. Professional installers avoid using Monomer on curved surfaces or long-term vehicle liveries for this reason.

All clamshell Heat Presses

Comparison: Monomeric vs. Polymeric Vinyl

| Feature | Monomeric Vinyl | Polymeric Vinyl |

| Plasticizer Chain | Short-chain (Simple) | Long-chain (Complex) |

| Outdoor Durability | 2–5 Years | 5–8+ Years |

| Shrinkage Risk | High (over time) | Low / Minimal |

| Best Application | Flat surfaces, indoor, short-term. | Slight curves, outdoor, long-term. |

| Price Point | Budget-friendly | Mid-range |

Frequently Asked Questions

Can I use Monomeric vinyl for car wrapping?

It is not recommended. Monomeric vinyl lacks the ‘memory’ and stability needed for curves. It will likely shrink or pop out of recesses within a few months. For vehicles, Polymeric or Cast vinyl is the professional standard.

Why is Monomeric vinyl cheaper?

The manufacturing process (calendaring) is faster, and the chemical plasticizers used are less expensive to produce than the long-chain polymers required for more durable films.

How can I tell the difference between Monomer and Polymer vinyl?

Visually, they look identical. However, if you stretch a small piece, Monomeric vinyl will often turn white at the stress point and tear more easily. Always check the manufacturer’s technical data sheet (TDS) to confirm the composition.