A Nozzle is a microscopic opening or tube within the print head of an inkjet printer (including Sublimation, DTF, DTG, and Eco-Solvent systems). A single print head contains hundreds, often thousands, of these precision-engineered channels. They are responsible for “firing” minute droplets of ink—measured in picoliters—with extreme accuracy onto the print media to form text and images.

Read more

Why It Matters: Impact and Use

In digital garment decoration, nozzle health is the single most important factor in maintaining consistent production quality. Understanding nozzle maintenance is a cornerstone of E-E-A-T (Expertise, Authoritativeness, and Trustworthiness), as it prevents the most common cause of hardware failure in the industry.

Longevity and ROI: Print heads are the most expensive component of an inkjet system. Regular maintenance of the nozzles—such as daily test prints or using cleaning solutions—protects the machine’s ROI (Return on Investment) and prevents costly replacements.

Print Quality and Banding: If a nozzle becomes partially or fully blocked, it results in “clogging.” This manifests as horizontal white lines across a print, known as banding, or inaccurate color reproduction. In high-resolution workflows like Direct To Film (DTF), even a few missing nozzles can ruin a transfer.

The Drying Challenge: Because the inks used in professional printing (especially white ink in DTF and DTG) are highly pigmented or contain solids like titanium dioxide, they can dry quickly inside the nozzle. If the printer is left idle without a maintenance cycle, the ink solidifies, leading to a “dead” print head.

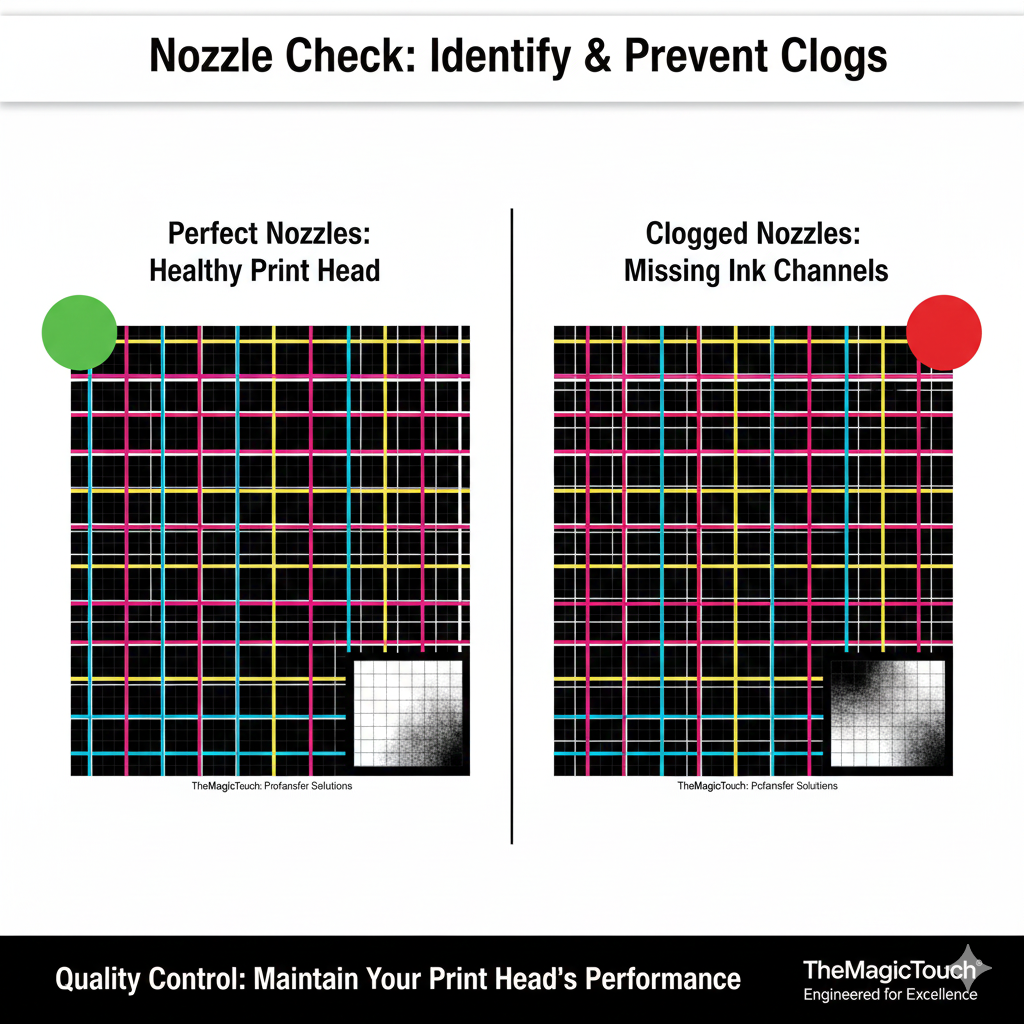

Nozzle Check Patterns: Operators perform a Nozzle Check to diagnose the health of the print head. This is a printed test pattern where each line represents an individual nozzle. A perfect pattern indicates the machine is ready for production; gaps in the lines indicate a need for a Head Cleaning.

Comparison: Nozzle Health Status

| Status | Visual Result | Production Impact | Required Action |

| Clear | Perfect, crisp images. | High-speed, high-quality output. | Continue standard operation. |

| Deflected | “Grainy” prints or blurry edges. | Lowered detail; color shifts. | Run a standard cleaning cycle. |

| Clogged | White lines (banding) through design. | Unusable prints; wasted media. | Run a deep clean or “power” flush. |

| Dried/Dead | Missing large sections of color. | Permanent hardware damage. | Manual cleaning or head replacement. |

Frequently Asked Questions

What causes nozzles to clog in DTF and DTG printers?

Clogs are primarily caused by ink drying inside the nozzle. This is common with white ink, which contains heavy pigments that settle if not agitated. Environmental factors like low humidity can also accelerate the drying process.

How often should I perform a nozzle check?

For professional printers (DTF, Eco-Solvent, Sublimation), a nozzle check should be performed daily. If the printer has been sitting idle for more than 48 hours, a check is mandatory before starting a production run.

Can a clogged nozzle be fixed?

Most minor clogs can be fixed through the printer’s internal cleaning cycles. For stubborn clogs, a ‘cleaning’ or ‘flushing’ solution can be used. However, if ink has completely dried and hardened inside the nozzle, the print head may need professional service or replacement.