A Nozzle Check is a critical diagnostic procedure performed by inkjet printers (such as Sublimation, DTF, and Eco-Solvent) to evaluate the functional status of the print head. The printer produces a specific test pattern—usually a series of stepped diagonal lines or grids—for each individual ink color. This allows the operator to verify that every microscopic nozzle is firing ink droplets correctly and precisely.

Read more

Why It Matters: Impact and Use

In professional digital printing, the Nozzle Check is the “first line of defense” against production failure. Mastering this diagnostic tool is a hallmark of E-E-A-T (Expertise, Authoritativeness, and Trustworthiness), as it prevents the most common quality issues before they waste expensive media.

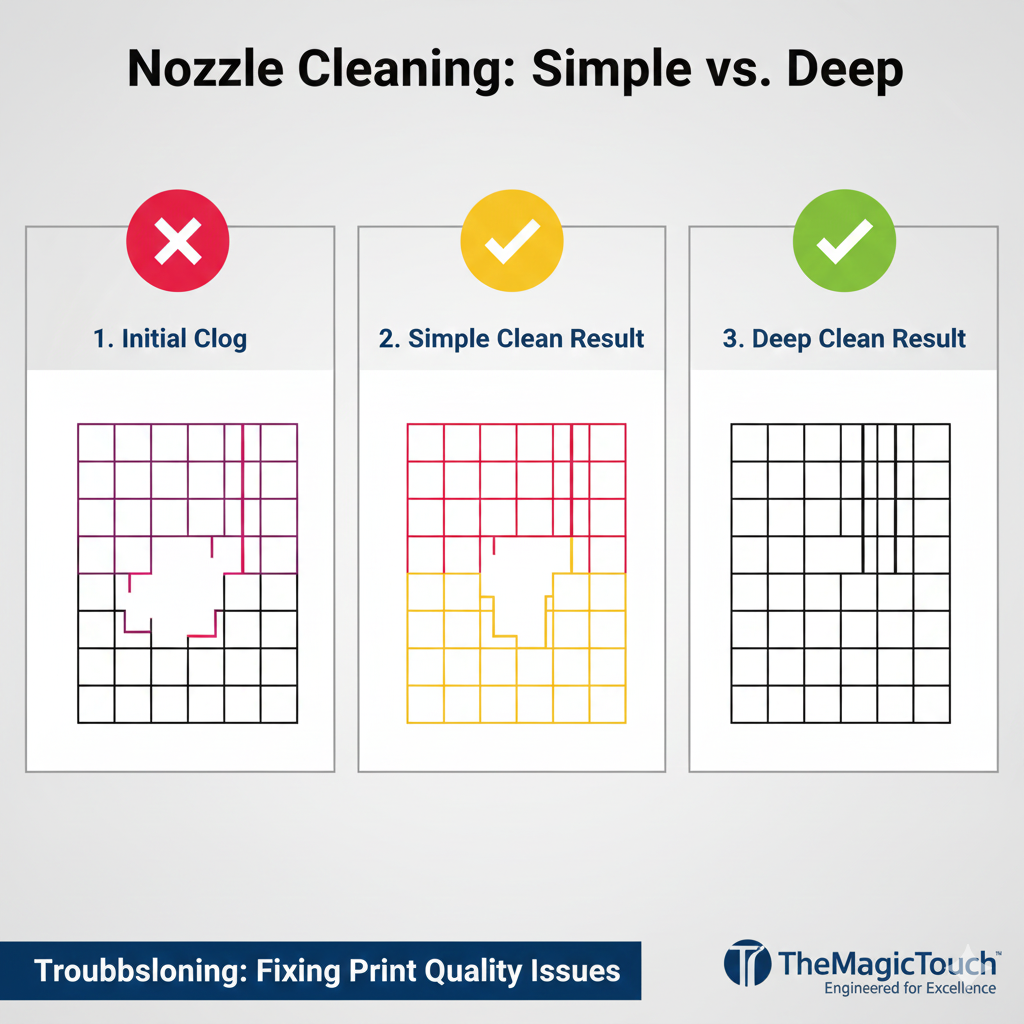

Hardware Longevity: By identifying a clog early, you can resolve it with a “Simple Clean” rather than a “Power Flush,” which uses significantly more ink and puts more wear on the print head’s delicate membranes.

Identification of “Banding”: A Nozzle Check reveals gaps or missing lines that cause horizontal “banding” across prints. By identifying these before a full job starts, you avoid wasting high-value materials like DTF Film or Sublimation Paper.

Color Accuracy: If the Cyan or Magenta nozzles are partially blocked, your final print will suffer from “color shifting” (e.g., your reds look orange). A Nozzle Check confirms that the CMYK balance is physically possible before you hit “Print.”

Preventative Maintenance: Performing a daily Nozzle Check keeps ink flowing. In systems like Direct To Film, where white ink contains heavy pigments that settle easily, the test helps ensure the ink hasn’t solidified in the channels.

All clamshell Heat Presses

Interpreting the Results

| Result | Appearance | Production Status |

| Clean Pattern | All lines are present and unbroken. | Ready: Proceed with high-quality printing. |

| Missing Lines | Visible gaps or “breaks” in the grid. | Warning: Run a cleaning cycle to clear clogs. |

| Deflected Lines | Lines are present but zigzag or overlap. | Warning: Indicates “clogging” or debris on the head. |

| Color Mixing | One color grid shows traces of another. | Critical: Indicates a “leaking” dampener or wiper issue. |

Frequently Asked Questions

How often should I perform a Nozzle Check?

For professional equipment like DTF or Sublimation printers, a nozzle check should be performed at the start of every production day. If the printer has been idle for several hours, a quick check is recommended to ensure no ink has dried in the tips.

What should I do if the Nozzle Check is missing lines?

You should perform a ‘Head Cleaning’ through the printer’s maintenance menu. After the cleaning cycle, print another nozzle check. If the lines are still missing, you may need a ‘Deep Cleaning’ or a manual wipe of the capping station.

Can a bad Nozzle Check ruin my print head?

The check itself won’t ruin the head, but ignoring the results will. Printing with clogged nozzles can cause heat buildup in the print head (since the ink acts as a coolant), potentially leading to permanent electronic failure.