Pressing (specifically post-pressing) is the critical final stage of the heat transfer process. It involves applying heat and pressure to a design a second time after the initial application and the removal of the carrier sheet (the plastic or paper backing). This stage is essential for Direct To Film (DTF), Heat Transfer Vinyl (HTV), and White Toner Transfer Paper to ensure a professional, retail-grade finish.

Read more

Why It Matters: Impact and Use

In the garment decoration industry, the “Pressing” step is what separates amateur products from professional merchandise. Mastering this technique is a core demonstration of E-E-A-T (Expertise, Authoritativeness, and Trustworthiness), as it directly impacts the longevity and “hand-feel” of the apparel.

- The T.Seal Advantage: For cotton garments, specialized sheets like T.Seal use a soft silicone coating to maximize fiber penetration. This results in a print that is not only more durable but also more flexible and breathable, significantly increasing the ROI (Return on Investment) through reduced customer returns.

- Enhanced Washability & Adhesion: The initial press bonds the adhesive to the surface of the fabric. The second press—without the barrier of a carrier sheet—liquefies the adhesive again, forcing it deep into the “valleys” of the textile fibers. This creates a mechanical lock that prevents peeling or cracking over time.

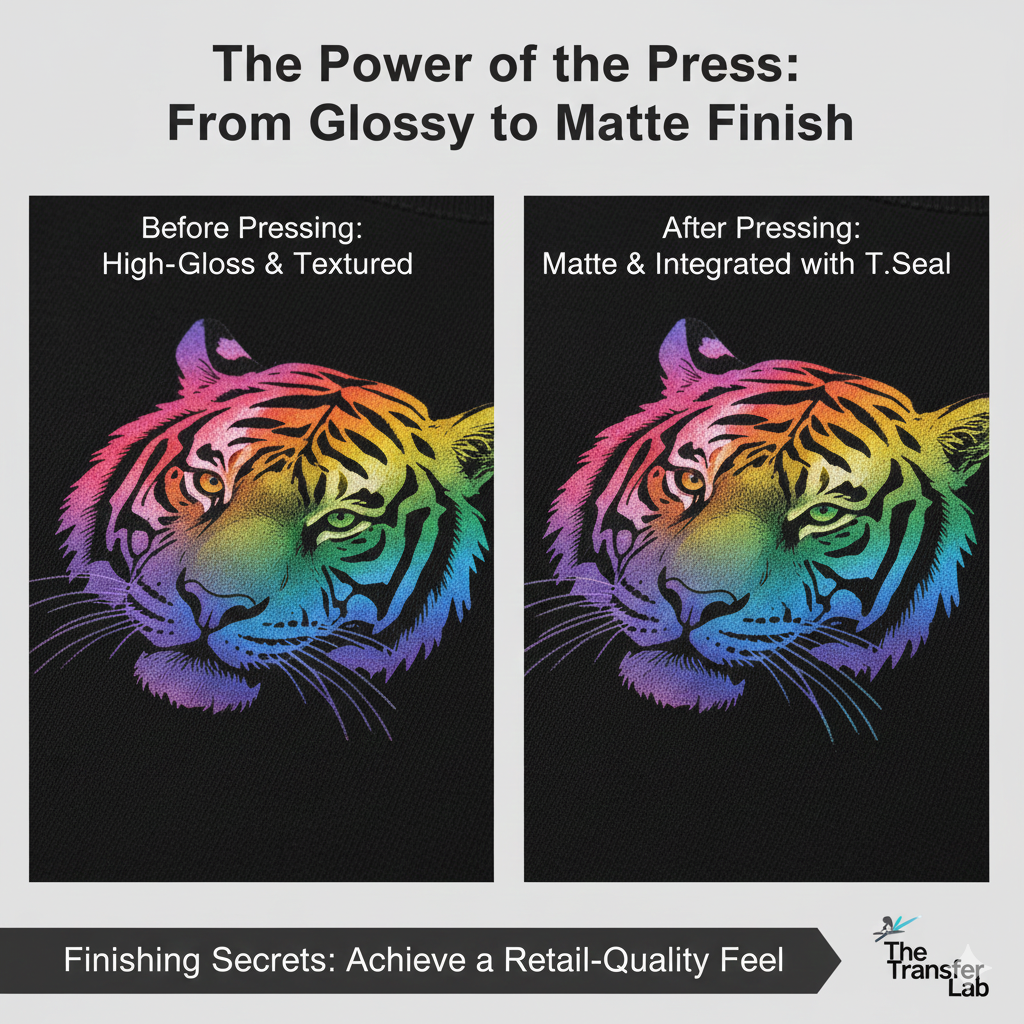

- Surface Aesthetic (Matte vs. Gloss): Freshly applied transfers often have a high-plastic sheen. Pressing the design with a finishing sheet like TheMagicTouch T.Seal or matte silicone paper removes this “shiny” look, providing a high-end matte finish that is preferred in modern fashion.

- Improved Hand-Feel: By flattening the transfer and embedding it into the weave, the design feels thinner and more integrated into the garment. This reduces the “heavy” or “rubbery” feeling often associated with lower-quality heat transfers.

All clamshell Heat Presses

Pressing Technique Comparison

| Metric | Initial Application | Post-Press (Finishing) |

| Carrier Sheet | Present (protects the film). | Removed (design is exposed). |

| Protective Layer | None needed (carrier is used). | Must use T.Seal, Teflon, or Silicone paper. |

| Pressure | Medium to Firm. | Firm (to force ink into fibers). |

| Dwell Time | 10–30 Seconds. | 5–10 Seconds. |

| Primary Goal | Adhesion to surface. | Durability and Finish. |

Frequently Asked Questions

Why do I need to press the design a second time?

The second press is vital for durability. It forces the adhesive deep into the fabric fibers, which prevents the edges from lifting and ensures the design survives repeated washing cycles.

What is the best paper to use for post-pressing?

TheMagicTouch T.Seal is the industry standard for cotton garments as it provides a matte finish and increases stretchability. Alternatively, Teflon sheets provide a glossy finish, and parchment paper provides a standard matte look.

Will pressing the design twice damage the shirt?

As long as you stay within the recommended temperature for the fabric (e.g., 140°C-160°C for cotton) and use a protective cover sheet, a short post-press of 5-10 seconds will not damage the garment.