Single Step refers to a streamlined heat transfer process where a printed design is applied directly from the transfer sheet to the final substrate (such as a T-shirt or bag) in one single heat press cycle. Unlike “Two-Step” systems, which require a secondary “marrying” process to add an adhesive layer, Single Step papers like TheMagicTouch TTC 3.1 already contain the necessary bonding chemistry within the paper’s coating.

Read more

Why It Matters: Impact and Use

In the fast-paced “Print-on-Demand” industry, the Single Step method is the gold standard for production speed and efficiency. Mastering this workflow is allowing businesses to maximize their output and decrease labor costs.

- Technical Precision: The chemistry of a Single Step paper is designed to release the transfer layer including the mirrored print on it (like TheMagicTouch TTC 3.1) or to bond the actual toner to the product (like TheMagicTouch CPM 6.2)

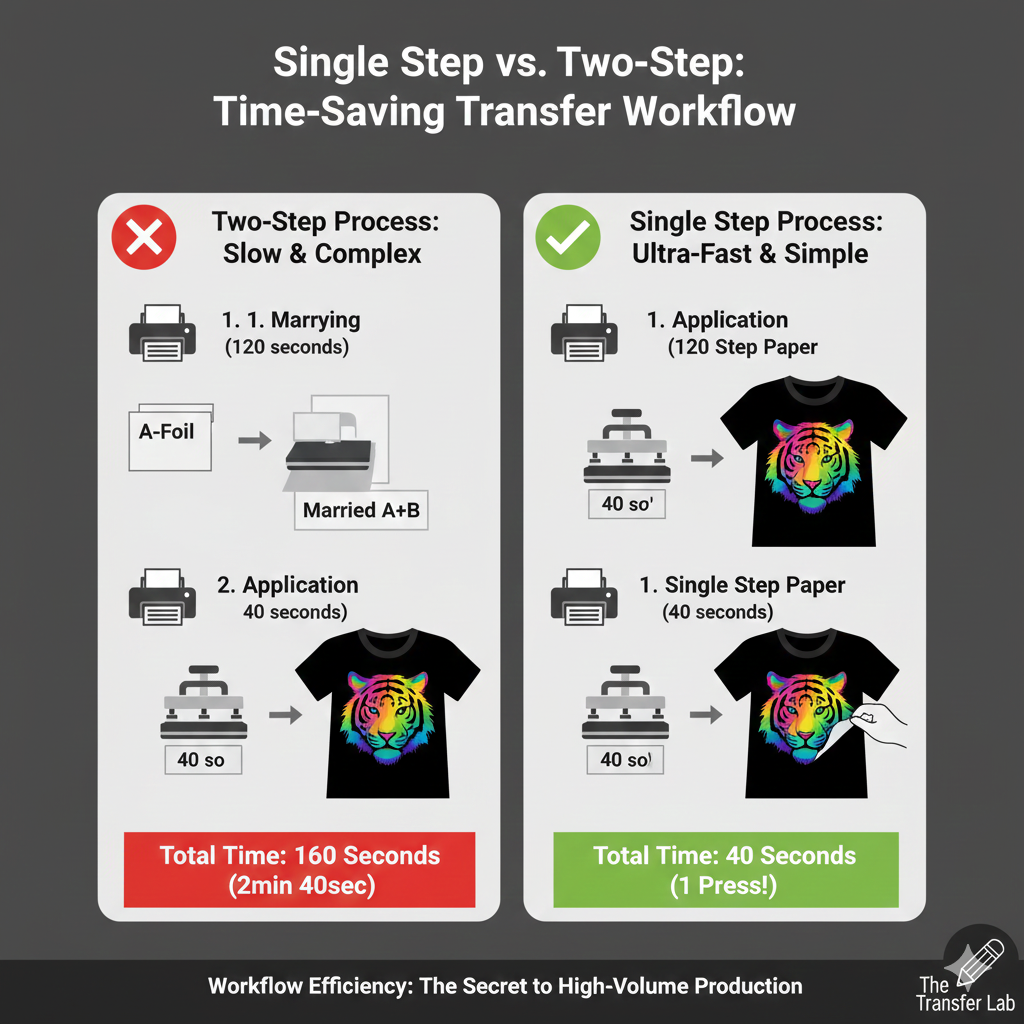

- Maximum Throughput: This is currently the fastest method to decorate a garment. By skipping the “marrying” step (the time spent pressing an A-foil to a B-paper), you effectively double your production capacity, leading to a much higher ROI (Return on Investment).

- Simplified Workflow: Because there is only one pressing cycle, there are fewer variables for error. This reduces the risk of “operator fatigue” and ensures a consistent result across hundreds of units.

- Compatibility: Single Step papers are typically used with CMYK Laser/LED printers. They are ideal for white or light-colored textiles where a white underbase (white ink or white adhesive) is not required.

All clamshell Heat Presses

Comparison: Single Step vs. Two-Step Transfers

| Feature | Single step (e.g., TheMagicTouch TTC 3.1) | Two-Step (e.g., TheMagicTouch WTT) |

| Press Cycles | 1 Press | 2 Presses (Marry + Application) |

| Production Speed | Ultra-Fast | Moderate |

| Garment Color | Light / White Textiles | Dark / Black / All Colors |

| Complexity | Low (Beginner Friendly) | High (Requires “Marrying” skill) |

| Key Advantage | Lowest Labor Cost | High Opacity / Vibrant on Darks |

Frequently Asked Questions

Can I use Single Step transfer paper on black T-shirts?

Generally no, but there are special Single Step transfer papers like TheMagicTouch OBM 5.4 that are specifically designed for darker colors and black T-shirts. These are often used with a Print & Cut process. For completely Free standing designs without Print & Cut a two-step process or DTF is required.

Is TheMagicTouch TTC 3.1 a Single Step paper?

Yes, TTC 3.1 is the world’s leading Single Step transfer paper for white and light-colored textiles, designed to work perfectly with OKI and other CMYK LED/Laser printers.

Does Single Step transfer paper feel heavy on the shirt?

No. Because it only transfers the toner and a very thin polymer layer, Single Step transfers typically have a very ‘soft hand’ or lightweight feel compared to traditional vinyl or thicker Two-Step transfers.